Super, thanks for this info!It appears that MT uses 2 optical IR sensors and cutouts in the carousel plastic to encode the position of which vial is under the home position.

I have still not decided whether to use optilcal sensors (which would encode start/end position) or to use RGB sensor which can encode the same informtion but possibly in a more granular way...

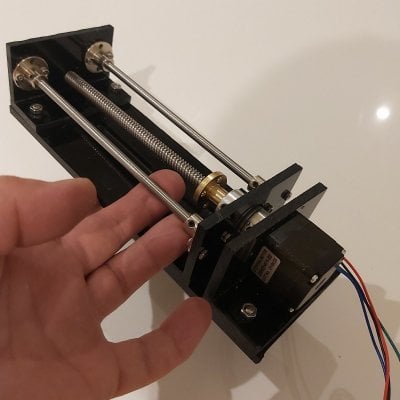

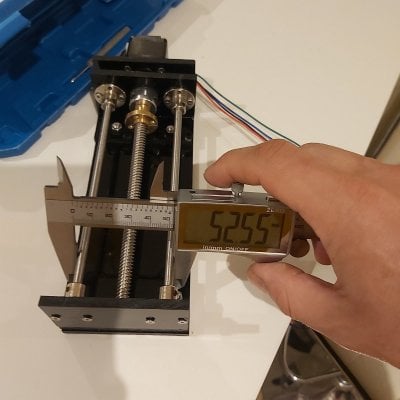

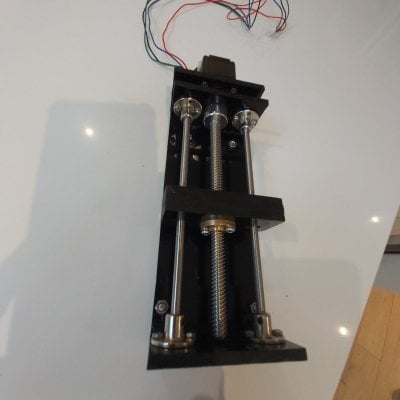

For the rig moving moving parts - it will be optical switches (definitely), the one thing I am a bit hesitant is whether to have 2 switches (start/end) or just 1 end switch.. I don't think I need 2 switches for each axis, but I look forward to your comments and will decide in due time..