Quick question:

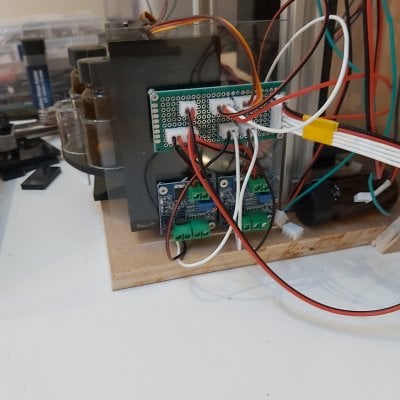

would it make economical sense in using the measurement part of this build (the light led sensor and the Arduino to control it) instead of buying the Hanna testers for alkalinity, magnezium, calcium ?

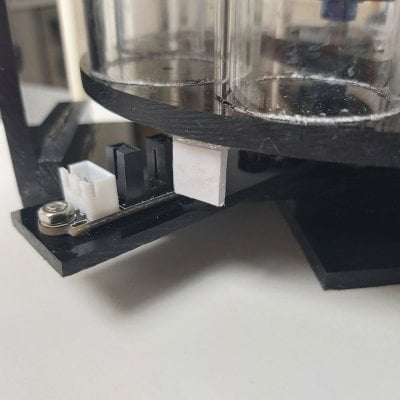

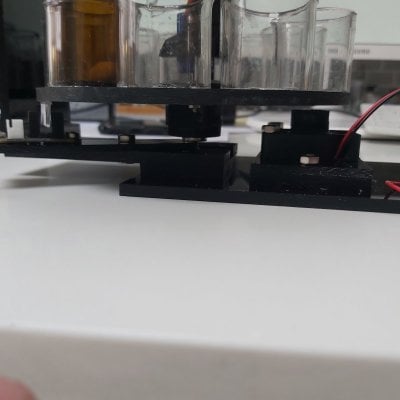

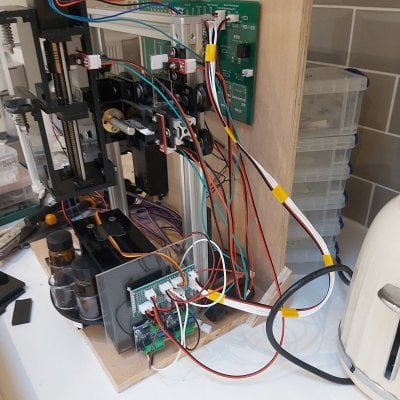

Obviously the tests will have to be done manually. Fill the bottle with water, fill it with reagent and push it into the above unit. (basically the same as Hanna units)

Should I invest time and money , considering the end result accuracy and other parameters ?

would it make economical sense in using the measurement part of this build (the light led sensor and the Arduino to control it) instead of buying the Hanna testers for alkalinity, magnezium, calcium ?

Obviously the tests will have to be done manually. Fill the bottle with water, fill it with reagent and push it into the above unit. (basically the same as Hanna units)

Should I invest time and money , considering the end result accuracy and other parameters ?