Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show Off and Discuss Your Red Sea Reefer Series

- Thread starter Broadfield

- Start date

- Tagged users None

- Joined

- Mar 2, 2019

- Messages

- 178

- Reaction score

- 176

I'm upgrading the sump on my 525. I put the gate valve on the return last year. The LFS says to use the flex hose that came with the sump for the drain because of the larger diameter. How do I control drain flow without a valve? If I have to go to the programming in Eco Tech Live for the return pump every time I need to make a minor adjustment that's going to be a hassle. I was planning on just hard plumbing it with 3/4 PVC and keeping the gate valve. The return line is 3/4 so what's the advantage of having the drain a larger diameter? I already have the Red Sea pieces and standard adapters I need to change the return and emergency drain to 3/4 PVC. I had already done the main return when I put in the gate valve.

Last edited:

- Joined

- May 6, 2019

- Messages

- 3,988

- Reaction score

- 7,897

If any part of your plumbing is 3/4 then the rest of it will be 3/4”. That means if you restrict it any where the max you can get out of it is the smallest diameter.

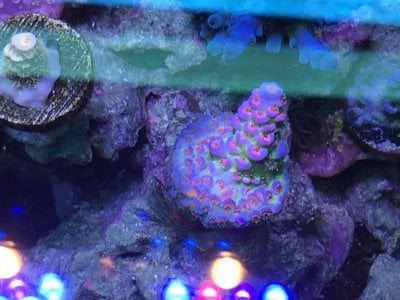

Finally a Red Sea reefer tank showcasing corals and not a sump packed with stuff.

I just don’t understand why reefer tank owners want to pack all that stuff down there? Is it really necessary? I have a reefer 250 filled with corals using only a skimmer, one tunze powerhead, and a dosing pump for two part.

- Joined

- Feb 7, 2018

- Messages

- 119

- Reaction score

- 115

It's been way longer than 1 week by now. Regardless of the validity of the situation, there definitely seems to be an agenda here.Sell it then! Why exploit every bad 750XXL for over a week?

It's been way longer than 1 week by now. Regardless of the validity of the situation, therSell it then! Why exploit every bad 750XXL for over a week?

It's been way longer than 1 week by now. Regardless of the validity of the situation, there is definitely an agenda here.Sell it then! Why exploit every bad 750XXL for over a week?

If any part of your plumbing is 3/4 then the rest of it will be 3/4”. That means if you restrict it any where the max you can get out of it is the smallest diameter.

Yeah, understood. Just sort of wondering why they want me to use the larger flex hose that is supplied with the new sump. Everythign seems to be working fine as it is.

I guess I would ask 'why' - I would have a quick release of some kind if you can - but again - the only time I've had to disconnect my pump (never so far) would be to replace it - and a union wouldn't really be that helpful (to me)@MnFish1 & @powers2001 I mostly agree with you, however, what do you think about adding a ball valve, or gate valve between the return pump and flex tubing? Or again best just keep as is?

I'm finally getting around to hard plumbing my reefer 350. I'm just now realizing that I have a new version of the sump (v3) than most of the pictures and plans that I've read. I've searched around and see that I'm not alone, but there are only a few examples of a hard plumbed manifold for the V3 sump.

Anyone else willing to share what they've got? I'm not sure if I should rotate the sump or keep it how it it's supposed to be. This is my first shot at hard plumbing anything so it would have been nice to more or less copy someone else's design like I had originally planned

Anyone else willing to share what they've got? I'm not sure if I should rotate the sump or keep it how it it's supposed to be. This is my first shot at hard plumbing anything so it would have been nice to more or less copy someone else's design like I had originally planned

I would not re-plumb it - only because I'm a total mess up trying to do these things - I would buy/do things that use the original setupI'm finally getting around to hard plumbing my reefer 350. I'm just now realizing that I have a new version of the sump (v3) than most of the pictures and plans that I've read. I've searched around and see that I'm not alone, but there are only a few examples of a hard plumbed manifold for the V3 sump.

Anyone else willing to share what they've got? I'm not sure if I should rotate the sump or keep it how it it's supposed to be. This is my first shot at hard plumbing anything so it would have been nice to more or less copy someone else's design like I had originally planned

Simplicity is a beautiful thing but I rarely seem to go that direction. I'd like to deal with the pain of complexity now, while the tank is down, so that hopefully things can be easier for me in the future. I think having a manifold with valves in a good place would make removing and changing out media reactors much easier, as well as being able to add and remove components as time goes on without having to re-plumb the whole thing.

I've decided to flip the sump 180*. I've got both of the drain pipes mostly mocked up but I'm sure I can make some improvements before gluing them down. Now comes the fun part of designing the manifold. I'm going to try and put it as high up as possible in the cupboard to give room for media reactors and other things.

I've decided to flip the sump 180*. I've got both of the drain pipes mostly mocked up but I'm sure I can make some improvements before gluing them down. Now comes the fun part of designing the manifold. I'm going to try and put it as high up as possible in the cupboard to give room for media reactors and other things.

- Joined

- May 6, 2019

- Messages

- 3,988

- Reaction score

- 7,897

You know by flipping it like that filter socks are going to be a bigger pain to change? Also by having it flipped and those other pipes are now going to limit what you can fit for a manifold. That piping consumes valuable space as you start building.Simplicity is a beautiful thing but I rarely seem to go that direction. I'd like to deal with the pain of complexity now, while the tank is down, so that hopefully things can be easier for me in the future. I think having a manifold with valves in a good place would make removing and changing out media reactors much easier, as well as being able to add and remove components as time goes on without having to re-plumb the whole thing.

I've decided to flip the sump 180*. I've got both of the drain pipes mostly mocked up but I'm sure I can make some improvements before gluing them down. Now comes the fun part of designing the manifold. I'm going to try and put it as high up as possible in the cupboard to give room for media reactors and other things.

You know by flipping it like that filter socks are going to be a bigger pain to change? Also by having it flipped and those other pipes are now going to limit what you can fit for a manifold. That piping consumes valuable space as you start building.

I'm open to all ideas as far as what would work best. Do you think it would be best to keep the sump in it's original orientation? I looked at your setup - very nice by the way. I saw you're using a separate pump for the manifold. I was hoping I could avoid that but I guess it's not a big deal.

- Joined

- May 6, 2019

- Messages

- 3,988

- Reaction score

- 7,897

The reason for the separate pump is because I lost allot of head pressure going to the tank via 1 pump and all the elbows. For manifold items I wanted to maintain a standard output or flow to feed my turf scrubber and UV. So I felt it was best to run two pumps. There are ways around this too.I'm open to all ideas as far as what would work best. Do you think it would be best to keep the sump in it's original orientation? I looked at your setup - very nice by the way. I saw you're using a separate pump for the manifold. I was hoping I could avoid that but I guess it's not a big deal.

Also a reason for two pumps was pure redundancy. If my main return fails I can swap in the accessories pump.

Thanks for the input. I think I'm going to go with your idea instead. I won't rotate the sump and I'll keep the drain pipes in the same place. I'll plan on running a second pump for the manifold.

- Joined

- Oct 13, 2019

- Messages

- 38

- Reaction score

- 16

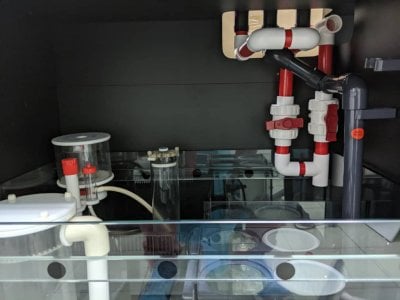

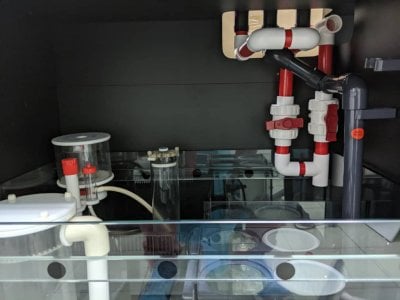

Hi Guys! I recently started a thread on my 425 XL build with a v3 sump. The placement of the return section i swear is a complete pain. But im getting there.

This is what i have for now. The return goes out to an external chiller, and comes back in on the original return line.

reason why there is an additional T and ball valve is to allow me to pump directly into the tank without going through the chiller when i have to.

everything is plumbed with 1/1/4 Sch40 pipes with industrial ball valves.

This is what i have for now. The return goes out to an external chiller, and comes back in on the original return line.

reason why there is an additional T and ball valve is to allow me to pump directly into the tank without going through the chiller when i have to.

everything is plumbed with 1/1/4 Sch40 pipes with industrial ball valves.

I've almost got the hard plumbing on my Reefer 350 (V3 sump) mocked up until I realized that the original drain pipes are 1 inch vs my 3/4 inch pipes.

Do I need to use 1 inch pipes for the drains or can I use my 3/4 inch pipes?

How about the return manifold? Should these be 1 inch pipes or is 3/4 inch okay?

Do I need to use 1 inch pipes for the drains or can I use my 3/4 inch pipes?

How about the return manifold? Should these be 1 inch pipes or is 3/4 inch okay?

Similar threads

-

- Locked

- Replies

- 2,974

- Views

- 75,629

- Replies

- 82

- Views

- 7,079

- Replies

- 24

- Views

- 2,305

- Replies

- 12

- Views

- 1,730

- Replies

- 41

- Views

- 8,573