Projects with Sam

5000 Club Member

View Badges

Partner Member 2024

Hospitality Award

Midwest Reefer

Rock Pool Reef Keepers

My Tank Thread

My Aquarium Showcase

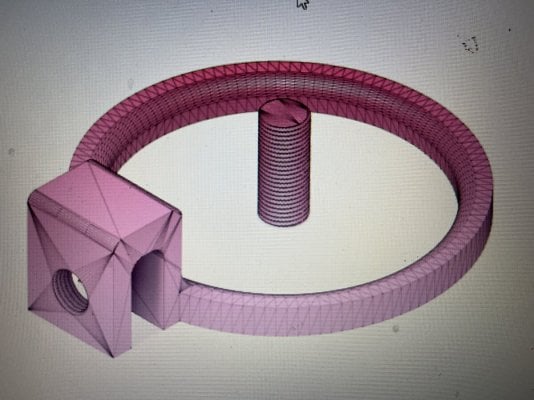

I've found that with the MK8 hot-end, you need to tighten everything up when its hot. Also, the heat break (filament guide tube between hot and cold sides) going into the top of the heat block should be tightened first, then the nozzle; ideally you'll bump the nozzle against the break and have ~1/2 a thread left so you know you've got them together.The nozzle maxes out at 260 C , I tried running it at that temp for a couple of minutes but still didn't budge

I ordered replacement silicone shields and have a bunch of extra nozzles from when I ordered the blue tubing to replace the junky white tubing that connects extruder to hot end. Just seems so crazy that both printers crapped out on me within 24 hours of each other

Also, if you're using a full metal hot-end, the capricorn tubing doesn't provide that much of a benefit; I've found it sometimes adds friction to the extrude.