Projects with Sam

5000 Club Member

View Badges

Partner Member 2024

Hospitality Award

Midwest Reefer

Rock Pool Reef Keepers

My Tank Thread

My Aquarium Showcase

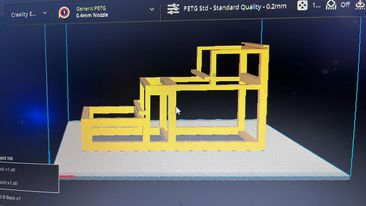

That is why core XY printers are so much better then bed slingers and why I am so surprised Prusa is still releasing bed slingers and expecting people to pay what they're asking.that is awesome, I am looking into purchasing a second printer. I can't keep myself satisfied with only one, ender 3 with the auto bed leveler and pei sheet. I am using PETG plastic and can hit about 65 mm/s , will have to look into the ender 5 model. wowzers !