Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What Do You Need 3d Designed & Printed (YouTube Channel)

- Thread starter ocpondpoacher

- Start date

- Tagged users None

@Gtinnel @ocpondpoacher

Don't shy away from PLA, it does not break down as fast you may think, PLA prints will more than likely out last the aquarium. All of my aquarium prints are PLA, have been in service for years, and have not had a single issue in saltwater or freshwater systems. You can make load bearing parts from PLA, it all depends on how you design your components.

Keep in mind that 3D printers have their applications and limitations. The mating surfaces and print layers they produce are not ideal for water retention, but it is possible to make can make water tight prints.

Don't shy away from PLA, it does not break down as fast you may think, PLA prints will more than likely out last the aquarium. All of my aquarium prints are PLA, have been in service for years, and have not had a single issue in saltwater or freshwater systems. You can make load bearing parts from PLA, it all depends on how you design your components.

Keep in mind that 3D printers have their applications and limitations. The mating surfaces and print layers they produce are not ideal for water retention, but it is possible to make can make water tight prints.

@Gtinnel @ocpondpoacher

Don't shy away from PLA, it does not break down as fast you may think. The required conditions for PLA to break down at a significant rate, would make it uninhabitable for the fish or coral. The PLA prints will more than likely out last the aquarium.

All of my aquarium prints are PLA, have been in service for years, and I have not had a single issue in saltwater or freshwater systems. Load bearing parts can be made from PLA, like any material, it all depends on how you design your components.

Keep in mind that 3D printers have their applications and limitations. The mating surfaces and print layers they produce are not ideal for water retention, but it is possible to make water tight prints.

Hey I was just reading another thread from earlier in the year where you mentioned this.Don't shy away from PLA, it does not break down as fast you may think, PLA prints will more than likely out last the aquarium.

When I first got my 3d printer I did print a part for my aquarium out of black pla and it was probably in my tank for around 6 months or so without causing any known issue before I took it. I took it out because I no longer needed it but I didn't see any obvious sign of degradation.

Solid, here is the Thingiverse file link for @TriggerFinger.Yes thats perfect!

Mermaid Voronoi Remix by Ocpondpoacher

The Voronoi is 2mm thick so print this thing with 100% infill.

I was not sure about the size so this mermaid is 250mm tall. This thing is big. Let me know if you need a smaller one. It won't work to just scale the object down because that will make the thickness of the Voronoi structure too small to print. 1/2 scale will make the thickness go from 2mm to 1mm and no way 1mm will work.

Is this the Hanna test kit you are talking about? Hanna Test Kit.I need something to mount all my hanna test and salifert test kits on for display under tank and to dry my tubes on when not in use

When a project is large and not very complex I prefer to create something that I can cut out with a CNC. I am thinking that could be the way to go on something like this. Shoot over some pictures of what all would be mounted in this test kit holder.

So about 9 or 10 inches? I'll ask her and see.Solid, here is the Thingiverse file link for @TriggerFinger.

Mermaid Voronoi Remix by Ocpondpoacher

The Voronoi is 2mm thick so print this thing with 100% infill.www.thingiverse.com

I was not sure about the size so this mermaid is 250mm tall. This thing is big. Let me know if you need a smaller one. It won't work to just scale the object down because that will make the thickness of the Voronoi structure too small to print. 1/2 scale will make the thickness go from 2mm to 1mm and no way 1mm will work.

@Gtinnel @ocpondpoacher

Don't shy away from PLA, it does not break down as fast you may think, PLA prints will more than likely out last the aquarium. All of my aquarium prints are PLA, have been in service for years, and have not had a single issue in saltwater or freshwater systems. You can make load bearing parts from PLA, it all depends on how you design your components.

Keep in mind that 3D printers have their applications and limitations. The mating surfaces and print layers they produce are not ideal for water retention, but it is possible to make can make water tight prints

I have been printing since 2012 and I rarely use PLA. The main reason is that I am always printing reef stuff and I purchase a decently large amount of ABS. Once I had the old printer dialed in printing ABS I just never took the time to switch back. I have some Matter Hackers Pro PLA that I use sometimes. I'll start using it more on applications that are not in consent contact with the water.

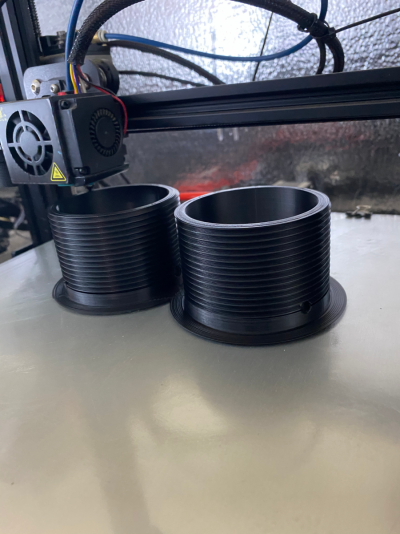

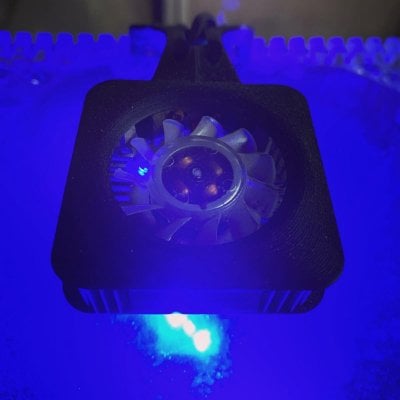

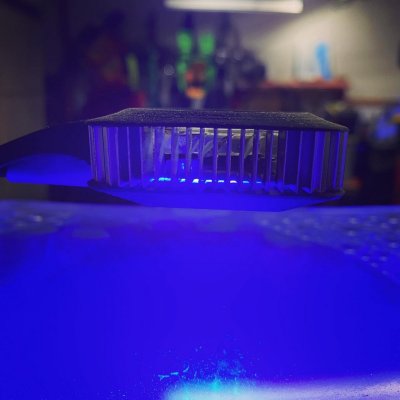

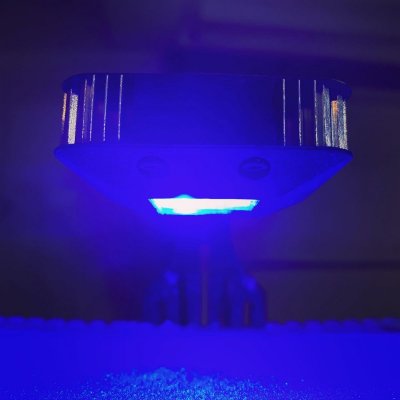

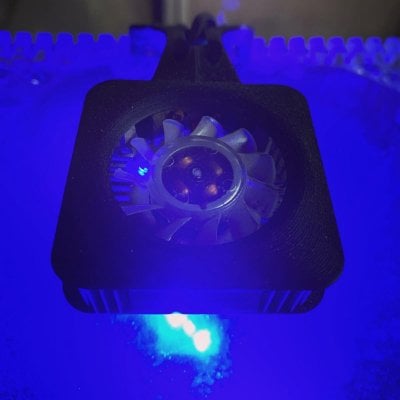

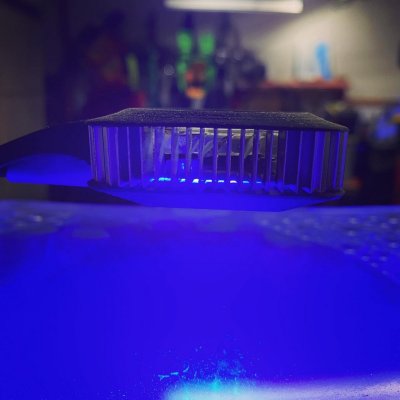

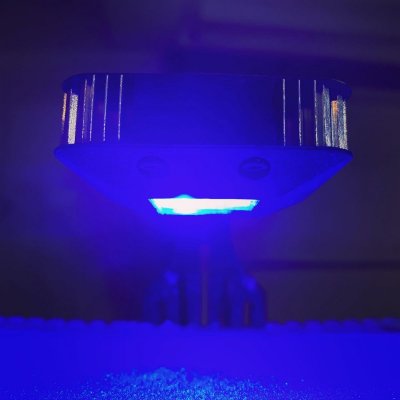

I am going to be making a 100% custom LED light and I just purchased Ice9 Thermal Conductive filament to make the heatsink. This is a nylon-based filament that is probably going to be very tricky to print with. I've made a ton of custom LED lights in the past and I have always been limited to using premade aluminum heat sinks. This time I won't be limited by anything but the ability to print. I'll create a thread when I start this project. Below are some pictures of the last light I made.

This will workSolid, here is the Thingiverse file link for @TriggerFinger.

Mermaid Voronoi Remix by Ocpondpoacher

The Voronoi is 2mm thick so print this thing with 100% infill.www.thingiverse.com

I was not sure about the size so this mermaid is 250mm tall. This thing is big. Let me know if you need a smaller one. It won't work to just scale the object down because that will make the thickness of the Voronoi structure too small to print. 1/2 scale will make the thickness go from 2mm to 1mm and no way 1mm will work.

I played around with some "exotic" filaments for some time and found that PLA was more than capable for what I use it for and hassle free. I constantly tweak my printer settings depending on the application. I mainly use my printers for prototypes, work holding, fixtures and assembly jigs.I have been printing since 2012 and I rarely use PLA. The main reason is that I am always printing reef stuff and I purchase a decently large amount of ABS. Once I had the old printer dialed in printing ABS I just never took the time to switch back. I have some Matter Hackers Pro PLA that I use sometimes. I'll start using it more on applications that are not in consent contact with the water.

I am going to be making a 100% custom LED light and I just purchased Ice9 Thermal Conductive filament to make the heatsink. This is a nylon-based filament that is probably going to be very tricky to print with. I've made a ton of custom LED lights in the past and I have always been limited to using premade aluminum heat sinks. This time I won't be limited by anything but the ability to print. I'll create a thread when I start this project. Below are some pictures of the last light I made.

Cool LED idea. Good luck with the filament and prints. Do you have an app to adjust the LED or is it manual adjustment? Ever thought about using a more printer friendly filament and using an aluminium insert to dissipate the heat?

If you want a custom aluminium housings machined, let me know. I have 5 axis capability and can get you a quote if you like.

- Joined

- Nov 10, 2018

- Messages

- 772

- Reaction score

- 1,045

I just want to say, bravo on releasing all your designs on thingiverse. With collaborative designs like this, we can all benefit, and improve on each other's work. Super awesome work too! None of my designs are that pretty, my stuff is just "functional".

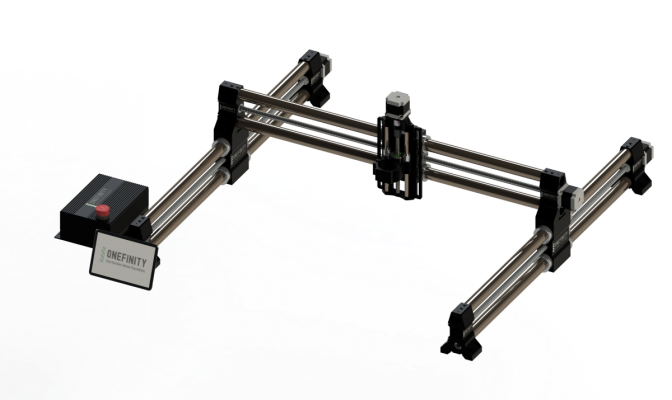

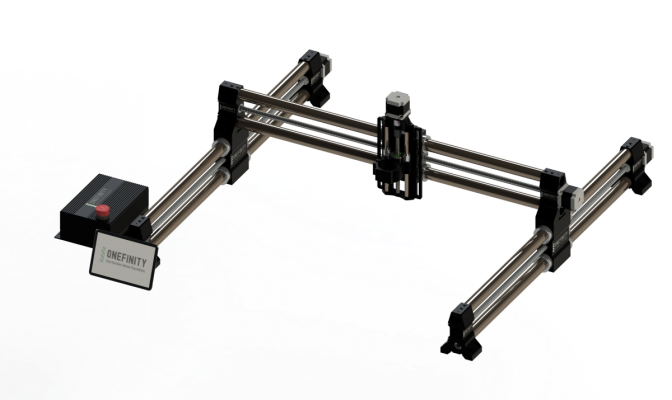

That is awesome that you have the 5 axis. I am for sure going to hit you up about that in the future. I sold my Shapeoko machine last year and am currently waiting for the Onefinity CNC which is supposed to arrive in February. I have been waiting for this machine for months and need it really back to finish some projects.I played around with some "exotic" filaments for some time and found that PLA was more than capable for what I use it for and hassle free. I constantly tweak my printer settings depending on the application. I mainly use my printers for prototypes, work holding, fixtures and assembly jigs.

Cool LED idea. Good luck with the filament and prints. Do you have an app to adjust the LED or is it manual adjustment? Ever thought about using a more printer friendly filament and using an aluminium insert to dissipate the heat?

If you want a custom aluminium housings machined, let me know. I have 5 axis capability and can get you a quote if you like.

The LED is currently being controlled with a bare-bones Arduino sketch that does nothing but set the desired PWM. I can only adjust the LEDs but modifying and loading the new sketch. I do plan on updating this but first I am trying to get the tank finished up and everything wired to the controller board.

I did start designing the app/web interface to control everything but it has a long way to go. I am very new to programming so I am sure that getting everything connection up to a web interface is going to be challenging. I am probably going to be using a Raspberry Pie Zero for the final version (I have Zero experience with Rasberry Pie).

Haha, some of my designs might look good but I am notorious for making things that don't "function" lol.I just want to say, bravo on releasing all your designs on thingiverse. With collaborative designs like this, we can all benefit, and improve on each other's work. Super awesome work too! None of my designs are that pretty, my stuff is just "functional".

Cool. A few friends started on printers, then moved up to desktop cnc routers and then they built their own. I've machined several machine frames for friends that wanted a rigid "desktop" mill, they featured 20-24mm linear rails. haha If you ever want to get into a neat DIY cnc project, look into epoxy granite machine frames. A few people have built very cool machines that are quite capable.That is awesome that you have the 5 axis. I am for sure going to hit you up about that in the future. I sold my Shapeoko machine last year and am currently waiting for the Onefinity CNC which is supposed to arrive in February. I have been waiting for this machine for months and need it really back to finish some projects.

The LED is currently being controlled with a bare-bones Arduino sketch that does nothing but set the desired PWM. I can only adjust the LEDs but modifying and loading the new sketch. I do plan on updating this but first I am trying to get the tank finished up and everything wired to the controller board.

I did start designing the app/web interface to control everything but it has a long way to go. I am very new to programming so I am sure that getting everything connection up to a web interface is going to be challenging. I am probably going to be using a Raspberry Pie Zero for the final version (I have Zero experience with Rasberry Pie).

What CAD software are you using?

Best of luck with the LED project. I built this: https://www.reef2reef.com/threads/3d-printed-5-gal-aquarium.628100/ , and it was difficult finding a small light for the system, tried to build my own light but gave up after I found one for that was perfect and adjustable.

The epoxy granite frames look solid. My plan at the moment is to build a 4'x8' rolling CNC and project assembly table but that might change.Cool. A few friends started on printers, then moved up to desktop cnc routers and then they built their own. I've machined several machine frames for friends that wanted a rigid "desktop" mill, they featured 20-24mm linear rails. haha If you ever want to get into a neat DIY cnc project, look into epoxy granite machine frames. A few people have built very cool machines that are quite capable.

What CAD software are you using?

Best of luck with the LED project. I built this: https://www.reef2reef.com/threads/3d-printed-5-gal-aquarium.628100/ , and it was difficult finding a small light for the system, tried to build my own light but gave up after I found one for that was perfect and adjustable.

Your fishbowl project is awesome. You really did a killer job with the filter design. I am going to post some questions in that thread shortly.

I started this Erlenmeyer flask 1.5 gallons closed-loop reef 7 years ago. The equipment on it kept blowing out so it got discontinued. I recently found the Erlenmeyer flask while cleaning out the garage and decided to give it another try. This time I printed all the parts. It has been running with tap water for about 2 months now. I still have to add a light, heater, stand, and controller.

I didn't think I have any pictures of the old 2014 design but I just found this living room shot with all 3 of my tanks in it. Left to right - 5g mixed reef, Erlenmeyer flask ( GSP & mushrooms), 25g mixed reef.

Thanks. The evaporation and not being able to stick your hand into the bowl without overflowing it was a real pain. Gained a new level of respect for nano tank keepers with my project.The epoxy granite frames look solid. My plan at the moment is to build a 4'x8' rolling CNC and project assembly table but that might change.

Your fishbowl project is awesome. You really did a killer job with the filter design. I am going to post some questions in that thread shortly.

I started this Erlenmeyer flask 1.5 gallons closed-loop reef 7 years ago. The equipment on it kept blowing out so it got discontinued. I recently found the Erlenmeyer flask while cleaning out the garage and decided to give it another try. This time I printed all the parts. It has been running with tap water for about 2 months now. I still have to add a light, heater, stand, and controller.

I didn't think I have any pictures of the old 2014 design but I just found this living room shot with all 3 of my tanks in it. Left to right - 5g mixed reef, Erlenmeyer flask ( GSP & mushrooms), 25g mixed reef.

Do you have any pics of your cnc?

That's some cool glass, would love to see some update pictures down the road.

The CNC is a Onefinity machine. https://www.onefinitycnc.com/. Below is the work table design. I am going to put it on casters so I can roll the table/machine around the garage. The bottom shelf is going to hold the dust collector and extra equipment. The extra length at the end of the table is going to be for assembling projects.Thanks. The evaporation and not being able to stick your hand into the bowl without overflowing it was a real pain. Gained a new level of respect for nano tank keepers with my project.

Do you have any pics of your cnc?

That's some cool glass, would love to see some update pictures down the road.

- Joined

- Oct 21, 2019

- Messages

- 854

- Reaction score

- 902

subscribed

The main draw back to moving it around on a table is that you are going to constantly twist the frame/bed. You will notice this become a problem when you take multiple passes over a flat surface. Maybe a 3 point mount system for the cnc bed or get a piece of granite and put the cnc bed over that? I would add a piece of thin foam under the granite, like most people do on rimless tanks.The CNC is a Onefinity machine. https://www.onefinitycnc.com/. Below is the work table design. I am going to put it on casters so I can roll the table/machine around the garage. The bottom shelf is going to hold the dust collector and extra equipment. The extra length at the end of the table is going to be for assembling projects.

Similar threads

- Replies

- 11

- Views

- 228

- Replies

- 1

- Views

- 122

- Replies

- 20

- Views

- 1,007