https://github.com/reef-pi/pH-Board This board!Nice ! What boards do you use and how does the data look ?

can I use the temperature from my sensor to optimize my ph reading? the ph is influenced by temperature.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

https://github.com/reef-pi/pH-Board This board!Nice ! What boards do you use and how does the data look ?

I struggled a little with the guide, ChatGPT got me through it. You can tell it what you’re doing and copy/ paste the code, it’ll tell you if it sees errors and give you something to copy and paste back in. You can also drop long error codes into it and it can usually figure them outI would like to move to the Grafana / Prometheus setup, but I am still doing my research, as I don't fully understand the "installation guide". It seems to assume the reader has a more intimate knowledge of Linux etc than I do. Working through all the steps so I at least get a partial understanding of what I'm doing. Then I can abandon the Adafruit idea.

I'm also running a Pi4 2GB. I have just upgraded an old desktop PC, so have the old one sitting as "spare" - thinking to set that up as the server.

Ah, cool. That would make this rather easy regarding adresses ^^https://github.com/reef-pi/pH-Board This board!

can I use the temperature from my sensor to optimize my ph reading? the ph is influenced by temperature.

Hi all, I'm a 10 year survivor of Apex. I will never, ever invest in their products again. More frustration than problems over the years. I came on here to see what its like in the DIY / open source world.

Just scanning through the pages my first reaction is ReefPi seems very technical and may have to spend lots of time troubleshooting. I'm not a developer but I work in technology and am fairly tech saavy.

- Is this something for a somewhat techy person but not an engineer?

- How much better than Apex?

- Is there a basic / newbie / beginner path? I dont need to control a ton of things but would be nice to automate things like lights and get some basic readings an monitoring

Back to more reading here! Thanks in advance!

I'm never used it for light, but you can just type float value in interface.I know that the PCA9685 supports 12 bit PWM, which accounts to 4096 steps. Is it possible to break the selected percentage down lower than 1% steps manually in reef-pi for sub 1% PWM output?

What problems do you want to solve by switching to reef-pi?Hi all, I'm a 10 year survivor of Apex. I will never, ever invest in their products again. More frustration than problems over the years. I came on here to see what its like in the DIY / open source world.

Just scanning through the pages my first reaction is ReefPi seems very technical and may have to spend lots of time troubleshooting. I'm not a developer but I work in technology and am fairly tech saavy.

- Is this something for a somewhat techy person but not an engineer?

- How much better than Apex?

- Is there a basic / newbie / beginner path? I dont need to control a ton of things but would be nice to automate things like lights and get some basic readings an monitoring

Back to more reading here! Thanks in advance!

Reef-pi accepts a float value 0-100, for jack control (Pwm connector ) and the individual drivers maps it back to corresponding range (0-4095 for pca9685) .. this should not require any software changes .. on reef-pi side, you should be able to get this working by standard pwm circuitry,.. software drivers should take care of restHey Ranjib, just a question on PWM with the PCA board for lighting.

I know that the PCA9685 supports 12 bit PWM, which accounts to 4096 steps. Is it possible to break the selected percentage down lower than 1% steps manually in reef-pi for sub 1% PWM output?

The reasoning behind this request is as follows-

My current Arduino setup uses a PCA9685 board for PWM, with Meanwell LDD -L and LDD-H drivers. The output is set by manually filling in the value from 0000-4095. I run my white channels at a 0001 or 0002 value, as anything higher is much too bright on my main channels. I also am not interested in adding specific moonlights at this time, as the main lights are excellent when appropriately dimmed.

Is this something that can be done easily in reef-pi, or does the ability to set/view actual steps versus 0-100% not currently exist?

reef-pi is a DIY project, it can be as hard as a furniture making/fine woodworking or even more (if you do not have any prior experience with computer stuff). Expect some learning, time involvement etc. It's an involved thing. its a project :-/

There are some off the shelf components that you can use to make it simpler and less cumbersome, albeit with compromises.

Its no where near as smooth experience as Apex. But it does the basic jobs (equipment control, temperature, ato control, ph monitoring etc ) fairly well. Many of us are running it for years now. I am of course biased :0) , I have been running 5+ tanks for 3+ years, few of them are more than 7 years old. All are on reef-pi from ground up, they are not super fancy, but also proper mix reef tanks (with beginner to intermediate level acros)

Hope this help,

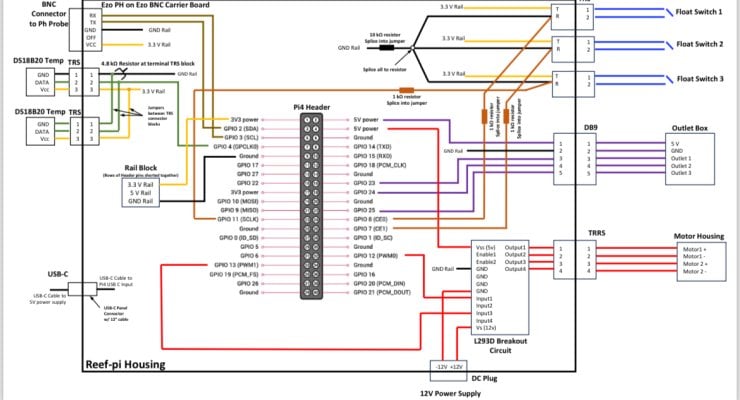

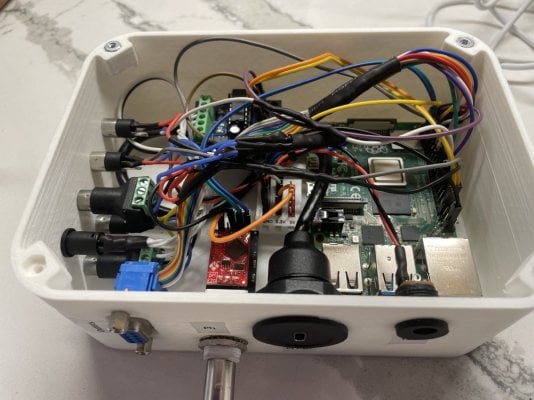

It wasn’t too bad for me but things that help are knowing how to use a multimeter for continuity/ resistance and voltage, good soldering / wire splicing skills with a good soldering iron (I prefer a solder gun which heats up really fast), using a heat gun and shrink sleaving, CAD and 3D printing. Programming skills come in handy but are more accessible with chatGPT etc. Will also save time and headache to do the more complicated circuits like L293D motor driver with an off the shelf breakout board so you can just connect leads to it.

An old version of my wiring diagram is below (had to make some changes, float switches each needed their own 10kohm resistor was biggest change) along with some pics. With time and patience it will be a rewarding project.

What problems do you want to solve by switching to reef-pi?

I can say that the biggest challenge that you are going to face in this way - commercial equipment like dosers, KH auto-testers etc just do not have any API or interfaces for reef-pi integration.

So you will use "Apex" any way because functionality is limited by available hardware, not software.

Thanks for the insight and feedback....

Thanks this is encouraging, altho would never attempt making fine furnitureAs I'll detail below I am looking to do the most basic stuff.

Oh good - I'm very comfortable with basic wiring, using a multimeter, soldering skills, shrink sleeving. But no experience with CAD or 3D printing. Will I need a 3D printer? I have basic programming skills. Thanks for sending the diagram. How large are those boxes you show with all of the circuits?

So I'm really only looking to do some basic things: read temp, PH, Salinity, and turn on and off things like lights and pumps.

Is this something that can be kept as simple or complex as desired?

I also read somewhere someone mentioned their chip catching fire and had someone not been there could've burnt down the house (always a consideration with reef tanks) but is this a real risk?

Ideally I'd love to make something a simple as possible to:

1) Reporting of Parameters:

- Temperature

- Salinity

- PH

2) Turn on and off outlets:

- LED lights (Kessil A360) and maybe ramp up and down like I could with my apex

- pumps / powerheads on an off as needed

- Skimmer

- Heaters

If I could do that without burning down the house or my bank account I'd be thrilled!

Actually if you already have Apex- why need to switch? For these anything is good enough.So I'm really only looking to do some basic things: read temp, PH, Salinity, and turn on and off things like lights and pumps.

Is this something that can be kept as simple or complex as desired?

I also read somewhere someone mentioned their chip catching fire and had someone not been there could've burnt down the house (always a consideration with reef tanks) but is this a real risk?

Ideally I'd love to make something a simple as possible to:

1) Reporting of Parameters:

- Temperature

- Salinity

- PH

2) Turn on and off outlets:

- LED lights (Kessil A360) and maybe ramp up and down like I could with my apex

- pumps / powerheads on an off as needed

- Skimmer

- Heaters

If I could do that without burning down the house or my bank account I'd be thrilled!

What do you mean by reef-pi does not have any api ? Entire ui is powered by api, and the api also exposes lower level direct controls instead of full feedback loopsAnd about esp32 integration in reef-pi 6.

I don't like idea of direct Pin control over wifi.

I can easily imagine how it will kill the tank/burn the house if wifi will be disconnected.

Thats why i'm building all system on smart, standalone moduls controlled over REST API.

Reef-pi do not have such functionality to work over API, so I have to make my own realization.

All "drivers" are hardcoded, no way to add random device without updating code of reef-pi.What do you mean by reef-pi does not have any api ? Entire ui is powered by api, and the api also exposes lower level direct controls instead of full feedback loops

I am totally lost with the e-mail alerts. I thought i had set it up correctly but apparently not. is there a link to tutorial.Just an update on this, I removed all temperature probes except for two and it has been stable. Ill try to add a probe every few days to see if I can find the culprit.

For some reason my google app password for alerts stopped working, so I generated a new password and this seems to be working again. I also created an adafruit.io account and set up alerts for extra safety.

I still need some help on how I can get my relay board to turn off my metal halide light.

Think you need to make your own softwareAll "drivers" are hardcoded, no way to add random device without updating code of reef-pi.

For example esp32 driver.

By the way, my pool request is still waiting

That’s is very different than saying reef-pi has no api. Drivers have specifics (like i2c protocol) that’s very different across .. hence driver types are fixed. There’s file based driver that you can use to integrate arbitrary devicesAll "drivers" are hardcoded, no way to add random device without updating code of reef-pi.

For example esp32 driver.

By the way, my pool request is still waiting