Hydros 101

What is a collective?

In order for a temperature sensor(Input) on one Control to operate a heater(Output) on a different Control, both devices need to be a member of the same collective. All shared Inputs, Outputs and associated Schedules are configured and managed from a common user interface. A collective may start small--possibly even as a single Control or Wave Engine--and scale to include multiple devices as tank automation needs and wants grow. In addition to sharing resources between Controls, other advantages of a collective include redundant brains and, potentially, redundant power.

Collective requirements

Before attempting to create a collective, review basic requirements:

• You must have command bus cables to connect devices. Typical command bus cables are sold in various lengths up to 15'. If Controls are further apart a data only command bus cable must be used.

• A minimum of one command bus terminator is required. For collectives which will include a XP8 and/or Wave Engine, two are recommended. If purchased as a Pro Pack, two command bus terminators are included.

• Collective members should be powered off while connecting command bus cables and terminators to avoid potential of electrostatic discharge damage.

• If collective includes XP8 and/or Wave Engine, power supply for each XP8/Wave Engine must be plugged in. If not, device will appear to function but outlets and direct drive pump ports will not operate.

• Collectives that do not include XP8 and/or Wave Engine should have only one power adapter plugged in powering all members.

• The ONLY exception to above is IF data only command bus is used. A single Control on each leg of the data only cable must have a power adapter.

• Controls/Wave Engines should be upgraded to current firmware prior to joining the collective.

• Wave Engine V1 and Wave Engine LE can not be the first member joined to the collective.

• Configuration of the first collective member, if exists, will be imported. Subsiquent additions will be wiped.

Creating the collective

From within the Hydros app, click on the three bars in the upper left corner then the + symbol in the top center to show all Controls/Wave Engines.

Click Create New Collective to proceed. Acknowledge minimum collective requirements and continue.

Specify the name of the collective and press Return. Upload Changes to complete.

Click the three bars in the upper left and select DEVICES to join additional members to the collective.

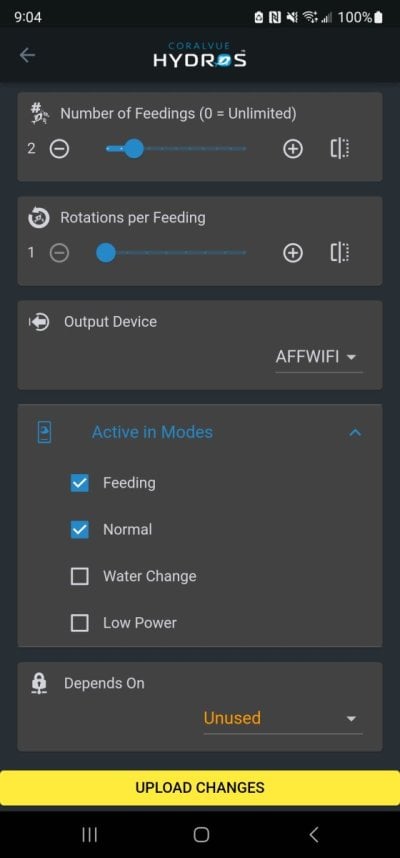

Click the + symbol in the bottom right to add members to the collective. Select the next collective member from the Hydros Device dropdown. Only devices which are not already members of a collective will appear in the dropdown. Wifi Master Priority should be set as Never for Wave Engine V1 and Wave Engine LE. All other devices may use Normal default. If one particular Control/Wave Engine is positioned closer to wifi auto feeders, plugs or strips then it may be configured as Wifi Priority Preferred. Only the Wifi Master will communicate with these devices. Upload Changes to continue.

Repeat device add for all remaining Controls/Wave Engines.

Up Next: MODES and basic collective OPTIONS.

What is a collective?

In order for a temperature sensor(Input) on one Control to operate a heater(Output) on a different Control, both devices need to be a member of the same collective. All shared Inputs, Outputs and associated Schedules are configured and managed from a common user interface. A collective may start small--possibly even as a single Control or Wave Engine--and scale to include multiple devices as tank automation needs and wants grow. In addition to sharing resources between Controls, other advantages of a collective include redundant brains and, potentially, redundant power.

Collective requirements

Before attempting to create a collective, review basic requirements:

• You must have command bus cables to connect devices. Typical command bus cables are sold in various lengths up to 15'. If Controls are further apart a data only command bus cable must be used.

• A minimum of one command bus terminator is required. For collectives which will include a XP8 and/or Wave Engine, two are recommended. If purchased as a Pro Pack, two command bus terminators are included.

• Collective members should be powered off while connecting command bus cables and terminators to avoid potential of electrostatic discharge damage.

• If collective includes XP8 and/or Wave Engine, power supply for each XP8/Wave Engine must be plugged in. If not, device will appear to function but outlets and direct drive pump ports will not operate.

• Collectives that do not include XP8 and/or Wave Engine should have only one power adapter plugged in powering all members.

• The ONLY exception to above is IF data only command bus is used. A single Control on each leg of the data only cable must have a power adapter.

• Controls/Wave Engines should be upgraded to current firmware prior to joining the collective.

• Wave Engine V1 and Wave Engine LE can not be the first member joined to the collective.

• Configuration of the first collective member, if exists, will be imported. Subsiquent additions will be wiped.

Creating the collective

From within the Hydros app, click on the three bars in the upper left corner then the + symbol in the top center to show all Controls/Wave Engines.

Click Create New Collective to proceed. Acknowledge minimum collective requirements and continue.

Specify the name of the collective and press Return. Upload Changes to complete.

Click the three bars in the upper left and select DEVICES to join additional members to the collective.

Click the + symbol in the bottom right to add members to the collective. Select the next collective member from the Hydros Device dropdown. Only devices which are not already members of a collective will appear in the dropdown. Wifi Master Priority should be set as Never for Wave Engine V1 and Wave Engine LE. All other devices may use Normal default. If one particular Control/Wave Engine is positioned closer to wifi auto feeders, plugs or strips then it may be configured as Wifi Priority Preferred. Only the Wifi Master will communicate with these devices. Upload Changes to continue.

Repeat device add for all remaining Controls/Wave Engines.

Up Next: MODES and basic collective OPTIONS.

Last edited: