Hi all, I'm setting up my first tank with a sump, and despite all the research i have done, I still have so many questions, so im hoping for some guidance. The tank is a "reef ready" seapora 90 gallon, with two holes in the bottom, a one-inch hole, and a 3/4 inch hole. for a sump i have a trigger system saphire 34. And for a return pump I chose a synchra sdc 7.0

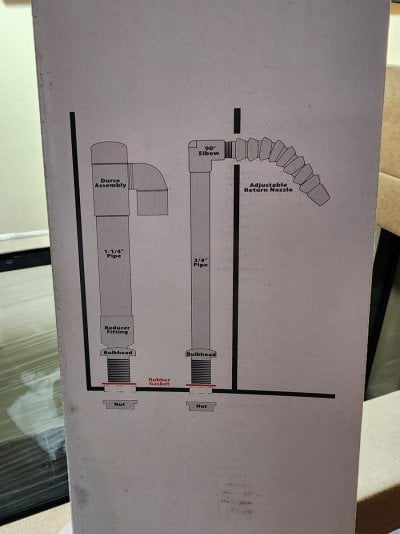

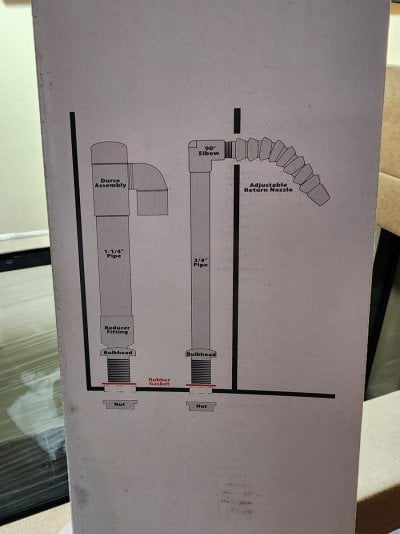

The original tank design looks like it calls for an durso style setup, and came with super cheap feeling hard plastic bulkheads with barbed ends. I was planing on switching it to a herbi style, and use the 3/4 inch for my main siphon, and the 1 inch for my emergency overflow. All plumbing will be hard plumbed.

I'm reading that I should invest in some quality sched 80 bulkheads like hayward. Just not sure If I should use glue, or threaded pvc. Also it looks like I should have a quality sched 80 gate valve to dial in the siphon, and probably some unions to disconnect. Im not sure if any or all of these should be glue fit or threaded. I want to be able to take things apart as needed to clean or if the tank ever needs to be moved.

Next, the sump intake has two long black 3/4 intake tubes, am I suppose to hard plumb to them with glue, dry fit them, or do they get removed for my own plumbing. If so, how far down do I need to run the plumbing into the sump. I'm assuming if I leave it too high the setup would be noisy.

For the return, it looks like I should run a short piece of flex directly off the pump to help with vibrations, and then convert to hard plumbing. How far up or down is ideal to place a ball valve and some unions? Glue vs threaded? Since I will utilize both holes for draining, I need to plumb up the backside of the tank for the return. Is it best to just 90 a pvc tube over top, and down in, or should i look into an hob water box type attachment to plumb into? And also where should I be drilling a drain for emergency siphon break on the return?

Also plumbing related, should I keep the original sizes all the way thru? At some point they have to be the same, as the two intakes on the sump are both 3/4. Im not sure where in line it's best to convert the 1 inch to 3/4. Also for the return line, what size plumbing should be ran off the pump to the overhang? And is it OK to run all 90 degree elbows thruout, or should multiple 45s be used? I haven't seen any images of people doing different sizes on the plumbing so I wasn't sure

Thanks for any helpful input you guys can share. I know this isn't going to go perfect for a first time, but as I need to order these plumbing parts (hard to source localy) I don't want to be in the middle of the build and find out I need another part.

The original tank design looks like it calls for an durso style setup, and came with super cheap feeling hard plastic bulkheads with barbed ends. I was planing on switching it to a herbi style, and use the 3/4 inch for my main siphon, and the 1 inch for my emergency overflow. All plumbing will be hard plumbed.

I'm reading that I should invest in some quality sched 80 bulkheads like hayward. Just not sure If I should use glue, or threaded pvc. Also it looks like I should have a quality sched 80 gate valve to dial in the siphon, and probably some unions to disconnect. Im not sure if any or all of these should be glue fit or threaded. I want to be able to take things apart as needed to clean or if the tank ever needs to be moved.

Next, the sump intake has two long black 3/4 intake tubes, am I suppose to hard plumb to them with glue, dry fit them, or do they get removed for my own plumbing. If so, how far down do I need to run the plumbing into the sump. I'm assuming if I leave it too high the setup would be noisy.

For the return, it looks like I should run a short piece of flex directly off the pump to help with vibrations, and then convert to hard plumbing. How far up or down is ideal to place a ball valve and some unions? Glue vs threaded? Since I will utilize both holes for draining, I need to plumb up the backside of the tank for the return. Is it best to just 90 a pvc tube over top, and down in, or should i look into an hob water box type attachment to plumb into? And also where should I be drilling a drain for emergency siphon break on the return?

Also plumbing related, should I keep the original sizes all the way thru? At some point they have to be the same, as the two intakes on the sump are both 3/4. Im not sure where in line it's best to convert the 1 inch to 3/4. Also for the return line, what size plumbing should be ran off the pump to the overhang? And is it OK to run all 90 degree elbows thruout, or should multiple 45s be used? I haven't seen any images of people doing different sizes on the plumbing so I wasn't sure

Thanks for any helpful input you guys can share. I know this isn't going to go perfect for a first time, but as I need to order these plumbing parts (hard to source localy) I don't want to be in the middle of the build and find out I need another part.

Last edited: