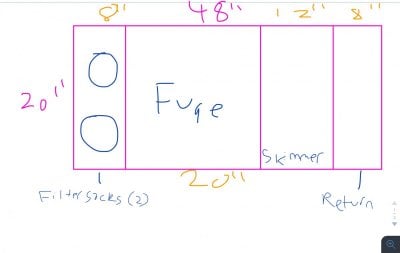

Actually I was thinking of using the inside of the tank. I’ve drawn a sketch to show what I want. But still plan on flattening the top.

As I already mentioned the euro brace will meet the same fate as the braces you were able to knock off. Make sure you use something better than weld on 4. There is a mix that is listed in this thread that will give you much better bond strength. A full top will give you much better strength than a euro brace in my experience.