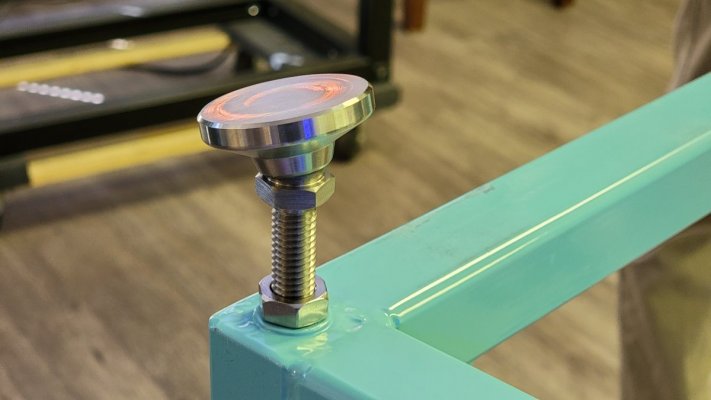

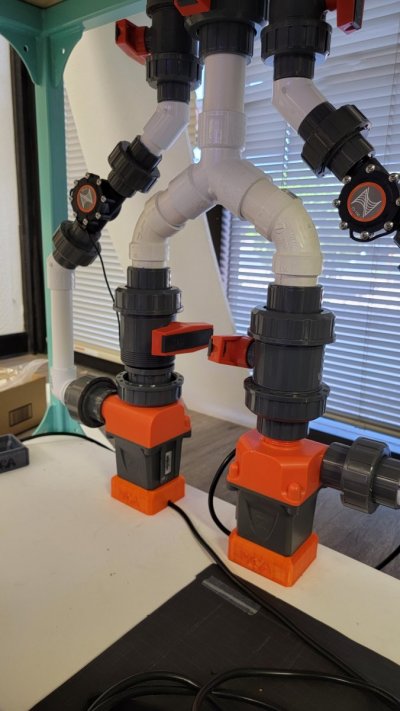

The plumbing sticks out about 8.5 to 9in , but we have it sitting in near the front windows in our lobby - so it's about 22 inches between the tank and the wall/windows.how far does the system have to sit from the wall with the plumbing and overflow box

for this build, the space was less of a concern than if it where sitting in my living room at home. If that where the case, i think I would have tried to make it a but more compact.