I have a 320 gallon display, 75 gallon sump, 30 gallon frag system all plumbed together. I dose based on 400 gallons of actual water.

Electricity has become increasingly expensive in the state I live in and solar is less economically feasible. This is all different discussion, but in an effort to remove some of the reliance on electricity.

I started discussing this in another thread but in an effort to not completely hijack that, I'm posting this idea here.

The idea would be to use a small tankless water heater, specifically the NR501-OD-NG.

The advantage of a tankless water heater to heat the fish tank would be that it is as on demand same as an electrode heater. Meaning it only fires when the pump calls for circulation through the system. The water heater I listed will run as low as .5 GPM (which is 30 gph) and as high as 5 gpm with a 100° temperature rise at 2 GPM which should be easy enough to do with a 200 gph pump. Not to mention the majority of the water that will circulate which would be fresh water would primarily be sitting in the " heat exchanger" made out of PEX In the sump. So if it is off for any amount of time, the water should hold at roughly 78°. When the pump calling for heat turns on it would be circulating 78° water through a 100° temperature rise.

Will pex do the trick for the heat exchanger because it's really only happy at 200° or less and we are getting close to that threshold in this system?

I'd love to hear some thoughts on the basic idea.

Electricity has become increasingly expensive in the state I live in and solar is less economically feasible. This is all different discussion, but in an effort to remove some of the reliance on electricity.

I started discussing this in another thread but in an effort to not completely hijack that, I'm posting this idea here.

The idea would be to use a small tankless water heater, specifically the NR501-OD-NG.

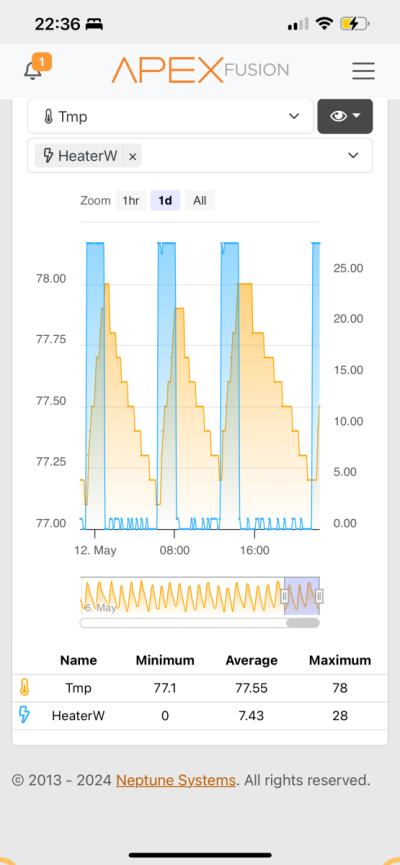

The advantage of a tankless water heater to heat the fish tank would be that it is as on demand same as an electrode heater. Meaning it only fires when the pump calls for circulation through the system. The water heater I listed will run as low as .5 GPM (which is 30 gph) and as high as 5 gpm with a 100° temperature rise at 2 GPM which should be easy enough to do with a 200 gph pump. Not to mention the majority of the water that will circulate which would be fresh water would primarily be sitting in the " heat exchanger" made out of PEX In the sump. So if it is off for any amount of time, the water should hold at roughly 78°. When the pump calling for heat turns on it would be circulating 78° water through a 100° temperature rise.

Will pex do the trick for the heat exchanger because it's really only happy at 200° or less and we are getting close to that threshold in this system?

I'd love to hear some thoughts on the basic idea.