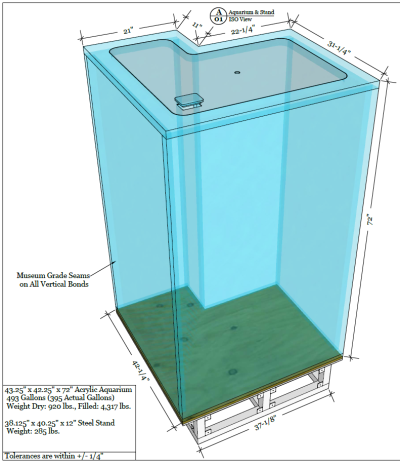

Current build is a 6' tall column style tank, only about 40" x 40" footprint. EST. 500 gallons.

Currently have (2) A500x Tuna Blue Kessil LED's with 35 degree reflector, manufacturer says light will penetrate 4' deep.

I could use some help with ideas on how to stock the tank with corals, obv. low light at bottom, but what would do well down there? How about up top with the 35 degree, is that too focused for some species at the top (thinking focused intensity)?

Any supplemental lighting suggestions in addition to the Tuna Blues?

Regarding flow, tank is setup for 10x true turnover at the DT. I can also pipe in additional returns if needed. Have 2 convective cycles setup for suction / supply at top, and bottom. Returns will be: TOP spray bar, Medium High, Medium Low. Each return will be loc-line fittings with WYE's so I can split it off in multiple directions.

RED is suction

BLUE is return from filter

monster tank, tall tank, 500 gallons

Currently have (2) A500x Tuna Blue Kessil LED's with 35 degree reflector, manufacturer says light will penetrate 4' deep.

I could use some help with ideas on how to stock the tank with corals, obv. low light at bottom, but what would do well down there? How about up top with the 35 degree, is that too focused for some species at the top (thinking focused intensity)?

Any supplemental lighting suggestions in addition to the Tuna Blues?

Regarding flow, tank is setup for 10x true turnover at the DT. I can also pipe in additional returns if needed. Have 2 convective cycles setup for suction / supply at top, and bottom. Returns will be: TOP spray bar, Medium High, Medium Low. Each return will be loc-line fittings with WYE's so I can split it off in multiple directions.

RED is suction

BLUE is return from filter

monster tank, tall tank, 500 gallons

Last edited: