I set up a used Red Sea Max E260 a few months ago and the seller gave me the pipe kit for the sump (no sump). I have never had a sump before and have no experience with plumbing but I wanted to give it a try anyway.

Equipment

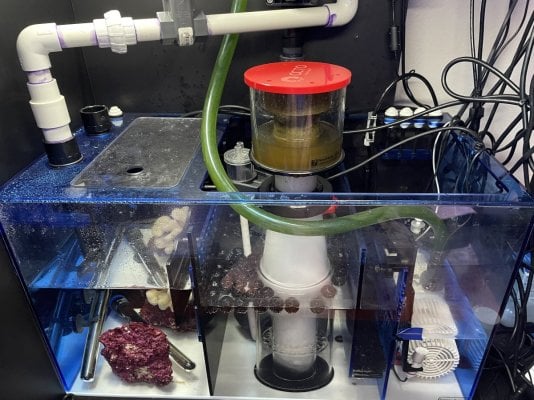

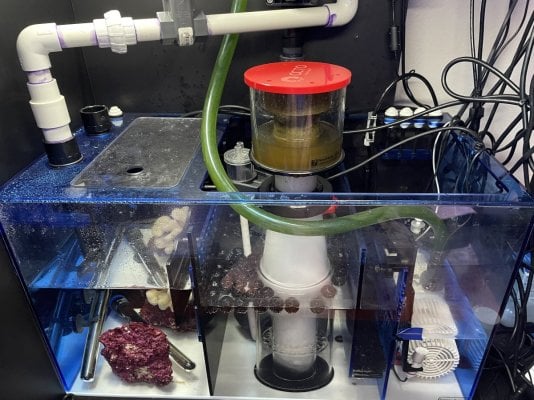

I found a good deal on a Trigger System Triton 26 v2 that fit nicely in the cabinet. I got a Tunze osmolator 3155 for my ATO and a matching Trigger Systems 10gal reservoir for my RODI water. I have a reef octopus 110 for my skimmer and a Reef Octopus Varios4 for my return pump. I have the stock pumps in each corner running and I put the closed off plugs in the bottom two corners as per the instruction from Red Sea.

Plumbing

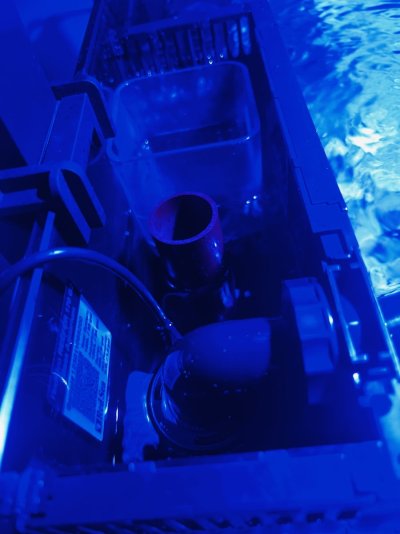

I hooked up the Red Sea pipe kit following the instructions provided but quickly realized their pipes down in the cabinet don’t line up with the sump I bought so I went out and bought some pipe and connectors (unions, elbows, and a gate valve). I then learned that Red Sea uses metric plumbing so I ordered some metric to standard pvc unions to solve the problem. I did my best to get everything measured and lined up, but it came out a bit messy. I used the tubing that came with the Red Sea kit for the return pump instead of hard plumbing it.

Problem

I cannot get my return pump section to stay even enough for my ATO to do its job properly. It inevitably drains enough in the return section and refills via the ATO until there is so much water in the system that it comes down the overflow. I think the water coming down the pipe from the back of the DT is not keeping a consistent flow for some reason. Also, the water level changes in the back of the DT (where the pipes are) when I think it should be only changing in the return pump area.

What I Have Tried

I started by filling the DT up to the downflow pipe. Then I filled up the sump almost completely full (1” to the top). I left the gate valve completely open and turned my pump to speed setting 4. I then adjusted my gate valve slowly till the downpipe got quiet (full siphon). Then tried to make very small adjustments over a long period of time to get the return pump section water level consistent. I have also tried varying speeds on my return pump. It always ends the same way where my ATO overfills the system.

Any suggestions would be very much appreciated as I have been battling it this issue for a few months now. Thanks!!

Equipment

I found a good deal on a Trigger System Triton 26 v2 that fit nicely in the cabinet. I got a Tunze osmolator 3155 for my ATO and a matching Trigger Systems 10gal reservoir for my RODI water. I have a reef octopus 110 for my skimmer and a Reef Octopus Varios4 for my return pump. I have the stock pumps in each corner running and I put the closed off plugs in the bottom two corners as per the instruction from Red Sea.

Plumbing

I hooked up the Red Sea pipe kit following the instructions provided but quickly realized their pipes down in the cabinet don’t line up with the sump I bought so I went out and bought some pipe and connectors (unions, elbows, and a gate valve). I then learned that Red Sea uses metric plumbing so I ordered some metric to standard pvc unions to solve the problem. I did my best to get everything measured and lined up, but it came out a bit messy. I used the tubing that came with the Red Sea kit for the return pump instead of hard plumbing it.

Problem

I cannot get my return pump section to stay even enough for my ATO to do its job properly. It inevitably drains enough in the return section and refills via the ATO until there is so much water in the system that it comes down the overflow. I think the water coming down the pipe from the back of the DT is not keeping a consistent flow for some reason. Also, the water level changes in the back of the DT (where the pipes are) when I think it should be only changing in the return pump area.

What I Have Tried

I started by filling the DT up to the downflow pipe. Then I filled up the sump almost completely full (1” to the top). I left the gate valve completely open and turned my pump to speed setting 4. I then adjusted my gate valve slowly till the downpipe got quiet (full siphon). Then tried to make very small adjustments over a long period of time to get the return pump section water level consistent. I have also tried varying speeds on my return pump. It always ends the same way where my ATO overfills the system.

Any suggestions would be very much appreciated as I have been battling it this issue for a few months now. Thanks!!