Just recapping the progress.

July 8th. 2024

No3 Levels: 130ppm down to 60ppm

5.75l of media = 260ml/min. ORP: -200

Effluent: 0ppm @ 260ml/min

Too much media, removed some on July 26th when DT reached 60ppm No3.

July 26th. 2024

No3 Levels: 45ppm

2.6l of media = 175ml/min. ORP: 0

Effluent: 6.5ppm @ 170ml/min

No3 stabilized and held at ~40ppm, starting to rise very slowly in DT, now 45ppm. Feeding heavy. Could be No3 bound in rock.

August 5th. 2024

No3 Levels: 40ppm*

4l of media = 200ml/min. ORP:-65

Effluent: ?ppm @ 200ml/min

Added another 1.4l of sulfur media. Haven’t tested effluent yet.

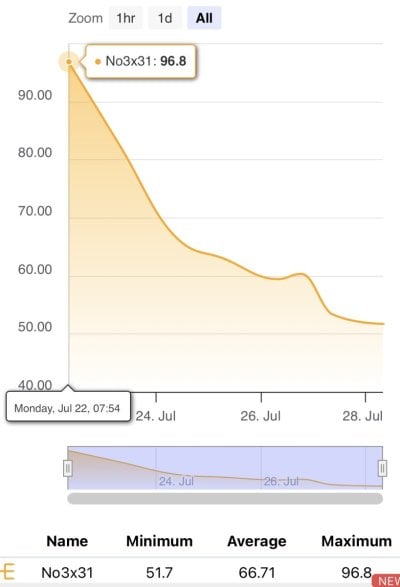

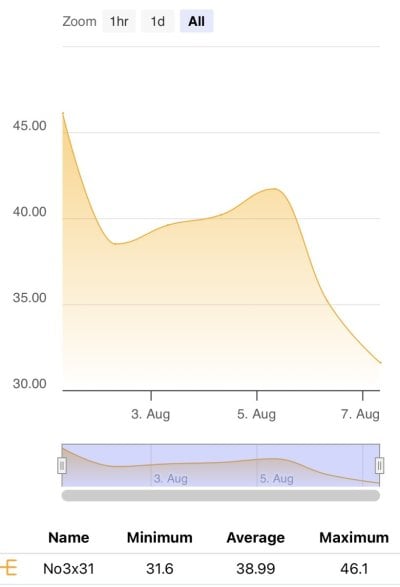

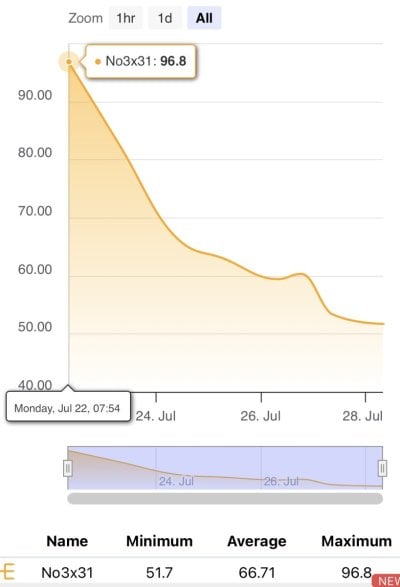

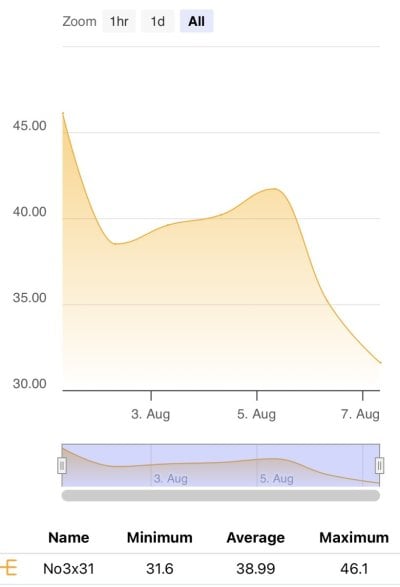

No3 Levels visualized by Trident NP on apex graphs:

July 8th. 2024

No3 Levels: 130ppm down to 60ppm

5.75l of media = 260ml/min. ORP: -200

Effluent: 0ppm @ 260ml/min

Too much media, removed some on July 26th when DT reached 60ppm No3.

July 26th. 2024

No3 Levels: 45ppm

2.6l of media = 175ml/min. ORP: 0

Effluent: 6.5ppm @ 170ml/min

No3 stabilized and held at ~40ppm, starting to rise very slowly in DT, now 45ppm. Feeding heavy. Could be No3 bound in rock.

August 5th. 2024

No3 Levels: 40ppm*

4l of media = 200ml/min. ORP:-65

Effluent: ?ppm @ 200ml/min

Added another 1.4l of sulfur media. Haven’t tested effluent yet.

No3 Levels visualized by Trident NP on apex graphs:

Last edited: