- Joined

- Sep 7, 2019

- Messages

- 589

- Reaction score

- 329

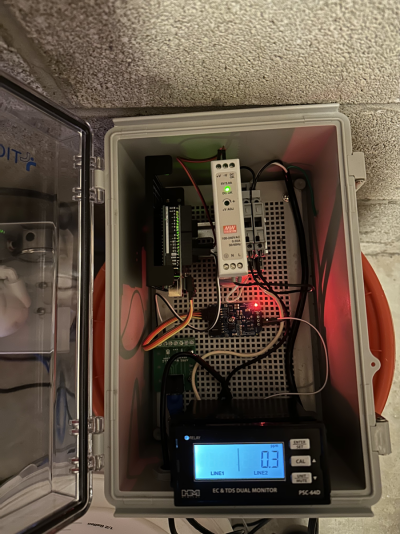

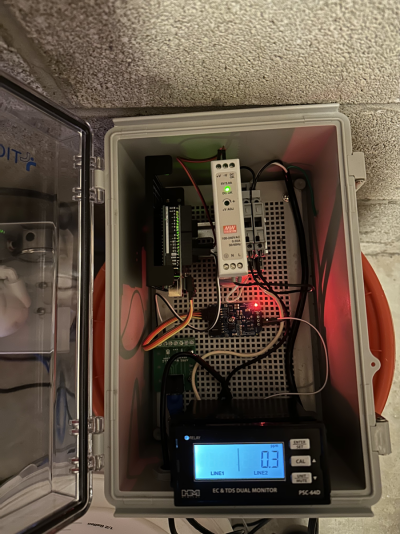

Hi everyone, I just wanted to show some of my work here. This system can tell your controller if it can allow RODI production or not. My RODI system has 2 (for redundancy) motorized ball valves electronically controlled by my Profilux 4, when these are open RODI production starts.

I used:

- a PSC-64D from HM Digital, to measure TDS down to 0.0 ppm (the classic TDS meters go down only to 0), the device puts out a 4-20mA signal.

- then I used an Arduino Uno Rev3, with a 4-20mA signal receiver to decode the signal and set the trigger for one of the Arduino's digital outputs to a specific voltage (1.7V in my case) if the TDS goes above 1.

- The digital signal is then received by a PLM-ADIN card from GHL, if the voltage goes above 1, it won't allow my Profilux 4 controller to open the valves of my RODI filtration system.

If anyone needs help with any of this or the code to make this run, just hit me up.

I used:

- a PSC-64D from HM Digital, to measure TDS down to 0.0 ppm (the classic TDS meters go down only to 0), the device puts out a 4-20mA signal.

- then I used an Arduino Uno Rev3, with a 4-20mA signal receiver to decode the signal and set the trigger for one of the Arduino's digital outputs to a specific voltage (1.7V in my case) if the TDS goes above 1.

- The digital signal is then received by a PLM-ADIN card from GHL, if the voltage goes above 1, it won't allow my Profilux 4 controller to open the valves of my RODI filtration system.

If anyone needs help with any of this or the code to make this run, just hit me up.