Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

reef-pi :: An opensource reef tank controller based on Raspberry Pi.

- Thread starter Ranjib

- Start date

-

- Tags

- controller raspberry-pi

- Tagged users Ranjib

NiceNope. After I removed the pots, I noticed the blue channel on that light wasn't dimming. Tested everything and came down to something in the driver. Had power, ground and pwm signal all the way to the driver.

Traced the pwm pin from the jst on the driver board to something that looked suspiciously like a smoked AO3400 mosfet. Just so happened to have a spare on my desk.

May not be that exact mosfet, but good enough. It's working correctly now.

Well, more like the d@mned thing is off like it should be for this time of night. We'll see tomorrow.. ;-)

No. There is plan to add a tasmota driver. I have to first get a compatible device first .Does reef-pi support control for smart switches running Tasmota?

- Joined

- Nov 20, 2018

- Messages

- 29

- Reaction score

- 44

The 8825 is a good standard driver that isnt overly priced. I have 3d printers and used about all the drivers out there. but dont need the fancy stuff that the higher end drives offer like stall protection thats used for sensorless homing. I can breadboard up a demo and even design a pcb for controlling the drives. I just dont know coding. you write code I can design the circuit and test it. I wonder if the pca9685 can be used to output the pulses to control a stepper.i mean, we have to do some design & coding work, and follow up testing/validation. The design work will involve at least settling on a common stepper driver (e.g. 8825??) for the standard build, the coding work i.e. HAL integration and any UI(driver??) work, and finally testing it out.

- Joined

- Nov 20, 2018

- Messages

- 29

- Reaction score

- 44

replace with quality relay.I think I know what is happening. Power off the reboot did nothing. Power off, tap the relay with a screw driver and reboot and it functions correctly. That suggests they are sticking due to arcing right? If that is the case what do I do?

- Joined

- Apr 19, 2019

- Messages

- 143

- Reaction score

- 79

These are boards with multiple relays and pins ready for the pi. They were cheap but I was following a guide. I am more than willing to get some quality relays, but lack the technical knowledge to know what to get. Can you reccomend some or provide a resource?replace with quality relay.

- Joined

- Feb 28, 2020

- Messages

- 22

- Reaction score

- 43

I have been using tmc2209 on my 3D printer and dosing pumps for awhile. They’re a lot quieter than the pololu drivers and support UART, so they’re very easy to configure (eg you can set the motor current programmatically rather than with a potentiometer).i mean, we have to do some design & coding work, and follow up testing/validation. The design work will involve at least settling on a common stepper driver (e.g. 8825??) for the standard build, the coding work i.e. HAL integration and any UI(driver??) work, and finally testing it out.

- Joined

- Nov 20, 2018

- Messages

- 29

- Reaction score

- 44

can you send me a pic? and do you know how to solder? it sounds like the relays arc welded. and once it starts it continues. what was the amp rating on the relay? most are 2 amp. also what is the power draw on the item plugged into it?These are boards with multiple relays and pins ready for the pi. They were cheap but I was following a guide. I am more than willing to get some quality relays, but lack the technical knowledge to know what to get. Can you reccomend some or provide a resource?

- Joined

- Nov 20, 2018

- Messages

- 29

- Reaction score

- 44

with 4988 or 8825 you can hard wire everything and control the stepper with just a single line pulse. (need a common ground but that wont be an exclusive pin, so not taking up a pin.) so would use 1 pin per doser pump. but wonder if a pca9685 could be used for the pulses to the driver? not to mention that 4988 are $1.60-$180 each and 8825 are $2 each on amazon. might be cheaper on aliexppress but the wait. 2209 are $6 each. and i dont think the noise will be that bad as dosers shouldnt run that much. and most aquariums arent that silent so would cover most of the noise.I have been using tmc2209 on my 3D printer and dosing pumps for awhile. They’re a lot quieter than the pololu drivers and support UART, so they’re very easy to configure (eg you can set the motor current programmatically rather than with a potentiometer).

- Joined

- Feb 28, 2020

- Messages

- 22

- Reaction score

- 43

True but with UART its 4 drivers on a 2 pin buswith 4988 or 8825 you can hard wire everything and control the stepper with just a single line pulse. (need a common ground but that wont be an exclusive pin, so not taking up a pin.) so would use 1 pin per doser pump. but wonder if a pca9685 could be used for the pulses to the driver? not to mention that 4988 are $1.60-$180 each and 8825 are $2 each on amazon. might be cheaper on aliexppress but the wait. 2209 are $6 each. and i dont think the noise will be that bad as dosers shouldnt run that much. and most aquariums arent that silent so would cover most of the noise.

- Joined

- Nov 20, 2018

- Messages

- 29

- Reaction score

- 44

does uart control steps and everything? I just thought it controlled the settings. but still used the old standards for enable direction and and step? if 2 pins control everything then that would be the way to go. is 4 drivers a hard limit or just what youre using? most printers use 4 drivers while some use 5. (dual z in my case not wired in series or parralle had 6 drivers so used 5 on a fysec f6) Ive never looked into how printer boards work just compiled the marlin. but have looked into controling steppers, and looked at what the pins do on older drivers. also what would be easier to code? 1 wire per dosing pump or serial bus control? also is 2209 uart? or spi? i2c? i know 2208 is 1 and 2209 is the other. think spi and i2c is the sameTrue but with UART its 4 drivers on a 2 pin bus

Last edited:

- Joined

- Apr 19, 2019

- Messages

- 143

- Reaction score

- 79

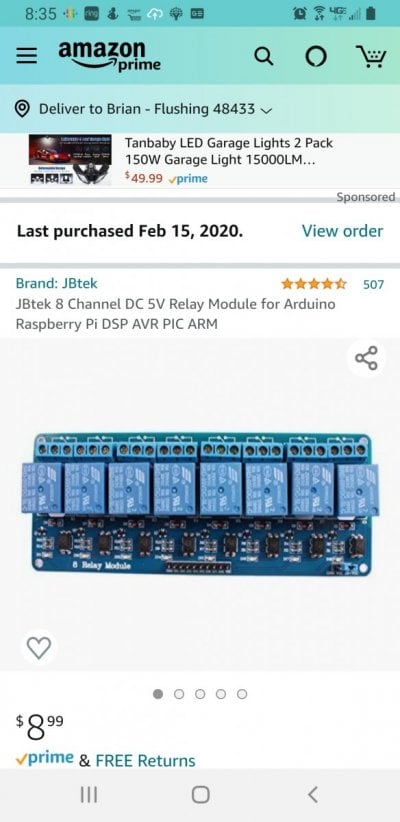

Sure thing. I bought an 8 relay unit and a 4 relay unit off Amazoncan you send me a pic? and do you know how to solder? it sounds like the relays arc welded. and once it starts it continues. what was the amp rating on the relay? most are 2 amp. also what is the power draw on the item plugged into it?

Attachments

- Joined

- Nov 20, 2018

- Messages

- 29

- Reaction score

- 44

it says its 10 amp rated. you using ac or dc? i dont remember the exact usage. also you solder?Sure thing. I bought an 8 relay unit and a 4 relay unit off Amazon

- Joined

- Feb 28, 2020

- Messages

- 22

- Reaction score

- 43

Tmc2209 is UART. You can set the speed using the serial interface and it maintains that indefinitely. That’s how I use them. You can address up to 4 drivers on one UART bus by setting address bits on the drivers themselves. They are sophisticated devices. I haven’t explored all their features and maybe there’s a way to address even more. For the noise, I agree with dosing it’s not a big deal. For AWC the steppers move pretty fast and noise becomes an issue. I haven’t tried the 8825, but the a4988 really fills the room when you run it that fast.does uart control steps and everything? I just thought it controlled the settings. but still used the old standards for enable direction and and step? if 2 pins control everything then that would be the way to go. is 4 drivers a hard limit or just what youre using? most printers use 4 drivers while some use 5. (dual z in my case not wired in series or parralle had 6 drivers so used 5 on a fysec f6) Ive never looked into how printer boards work just compiled the marlin. but have looked into controling steppers, and looked at what the pins do on older drivers. also what would be easier to code? 1 wire per dosing pump or serial bus control? also is 2209 uart? or spi? i2c? i know 2208 is 1 and 2209 is the other. think spi and i2c is the same

- Joined

- Nov 20, 2018

- Messages

- 29

- Reaction score

- 44

ive used that brand before with no issues, but with chinese knock offs who knows if i had real, or if yours are real. I also never used mine with much power it was an amp or 2 of 12v dc. heres a compatible part ( https://www.digikey.com/en/products...er-brumfield-relays/ORWH-SH-105D1F000/4925028 ) from a repitable supplier, but the cost it might be worth buying another and hoping it was just a fluke.Its controlling AC 120. Yes I know how to solder. Not great, but well enough for connectors and plugs.

- Joined

- Nov 20, 2018

- Messages

- 29

- Reaction score

- 44

well my thing is I think I would need atleast 8 if not 9 dosers for everything. I dont know if pi has multiple uart pins. and the number of dosers needed is why i was wondering if pca9685 could be used to deliever the pulses. each 9685 has 16 output and can be chained together to give massive number of outputs using just i2c. and If i design a board it can have 48 output easy, which should be more than enough for dosers and anything else that the and the pwm powers the doser, the faster the pwm the faster the doser doses, but think the pi uses 1 pwm for everything, so not sure how it works on that side, or how to limit the number of pulses.Tmc2209 is UART. You can set the speed using the serial interface and it maintains that indefinitely. That’s how I use them. You can address up to 4 drivers on one UART bus by setting address bits on the drivers themselves. They are sophisticated devices. I haven’t explored all their features and maybe there’s a way to address even more. For the noise, I agree with dosing it’s not a big deal. For AWC the steppers move pretty fast and noise becomes an issue. I haven’t tried the 8825, but the a4988 really fills the room when you run it that fast.

- Joined

- Apr 19, 2019

- Messages

- 143

- Reaction score

- 79

Those aren't too bad. Only way I would want to just rebuild is if any of the issue may be due to theive used that brand before with no issues, but with chinese knock offs who knows if i had real, or if yours are real. I also never used mine with much power it was an amp or 2 of 12v dc. heres a compatible part ( https://www.digikey.com/en/products...er-brumfield-relays/ORWH-SH-105D1F000/4925028 ) from a repitable supplier, but the cost it might be worth buying another and hoping it was just a fluke.

Is there muxh chance any part of the board would cause it? That would be an argument to rebuild. Otherwise the digikey relays aren't very expensive.ive used that brand before with no issues, but with chinese knock offs who knows if i had real, or if yours are real. I also never used mine with much power it was an amp or 2 of 12v dc. heres a compatible part ( https://www.digikey.com/en/products...er-brumfield-relays/ORWH-SH-105D1F000/4925028 ) from a repitable supplier, but the cost it might be worth buying another and hoping it was just a fluke.

- Joined

- Nov 20, 2018

- Messages

- 29

- Reaction score

- 44

if its sticking till you tap it its arc welded. the tap breaks the weak weld. but once it arc welds, it builds carbon, and then then it becomes more prone to arc due to increased resistance from the carbon causing it circle and get worse. i was looking at 8 port you bought for $9 where the digikey are $12 for just the relays plus shipping.Those aren't too bad. Only way I would want to just rebuild is if any of the issue may be due to the

Is there muxh chance any part of the board would cause it? That would be an argument to rebuild. Otherwise the digikey relays aren't very expensive.

Similar threads

- Replies

- 2

- Views

- 247

- Shipping Available

- Replies

- 2

- Views

- 223