- Joined

- Mar 22, 2017

- Messages

- 67

- Reaction score

- 37

Thought I would start a thread for our in-wall rebuild.

Background

When we built our house ~15 years ago, we found a floor plan that was great for an in-wall. The garage had a double deep bay that backed up to the family room and would become a storage and support room. My wife and I spent an entire afternoon with a tape measure and painters tape mocking up what the wall would look like with a tank framed into it. We had two dedicated breakers wired to opposite sides of the tank to create redundancy and split the life support systems. Miracles built a great tank for us and the tank was wet within a week of moving into the house.

Fast forward 15 years; the closed loop is gone, we've gone through multiple generations of lighting from MH/VHO to Kessils/VHO, back to MH w/T5 and to XR30 G4 Pros and T5s. The tank had had it's good years and bad. There were a number of years where I was traveling internationally for work a lot and while I could monitor the tank with our Neptune, it was rough and over time we lost most of the SPS and the tank became host to some simpler corals, RBTAs that have split too many time and clowns.

It was time to drain the tank and start fresh, but if we were going that far, it didn't make sense to keep the tank as-is. Most recommend to strip and re-seal after 10-15yrs and while everyones mileage can vary, I didn't want to rebuild everything just to have problems down the road and wish I had cut the tank apart and rebuilt. Our first thought was, let's try acrylic. It's lighter, easy to get, doesn't have a history of catastrophic seam failures and we could make a few changes from the original design. After some soul searching, I couldn't pull the trigger on acrylic. I think back to all the times of going after the front glass with a razor blade and acrylic wasn't going to support my maintenance habits. Our local fish/coral shop begged me not to do acrylic and knowing my "retentive" habits, threatened to take me out on their maintenance runs in the valley to see what Acrylic scratches looked like and if I could live with it. I know LOTS of people on this board and others are very successful with acrylic and I don't want this to be a flame fest on the virtues of Acrylic versus Glass.

The Future

So glass it is. I checked around to see who the glass builders of the day were (insert 15yr gap) and while there are a few new ones out there, most didn't return emails or calls with the exception of Miracles. Derek emailed me back within hours and we started talking about the old tank and what we would do differently this time. Turns out, the guys on the floor remembered the original tank and offered a few suggestions. Drawings were exchanged and we got in the build queue. Tank ordered 4/30 and we are looking at about 9-weeks given their current backlog. We extended the depth and removed all of the closed loop features from the first tank. I seriously looked at making the tank wider and taller, but it would have been a MAJOR hassle and required some extensive work to the wall.

About the only thing I didn't like about the original tank was the way we did the overflow. An acrylic sheet with teeth was added to the back of the tank. Over the years, the acrylic started to buckle and I was concerned it was putting stress on the vertical seams in the back of the tank. A couple of the teeth had broken over time too. For the overflow this time, we are going with a 20" EMS from Taylor.

Equipment List (Some new, some reused)

Miracles Aquariums custom in-wall tank

Exotic Marine Systems overflow

Apex Classic

Return #1 | Neptune Core 15 w/Arctica Chiller

Return #2 | Neptune Core-15 w/Pentair 80w UV

MRC Dual Beckett simmer w/Pan World 150PS and automated neck cleaner

Clear Water CW-200

3ea Radion XR30-G4 Pro LED w/diffusers

4ea 54W ATI Blue-Plus T5 (0-10v controlled)

4ea Vortech MP-40s

DIY Auto-Top off

Neptune DOS for automated water changes

GHL Doser2 (Alk/Kalk/Mg)

Sump

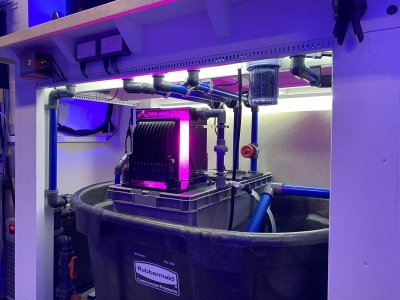

Sump is currently a rubbermaid 100g stock tank. It works well for storing extra rock and system volume, but I'd like like it to be a bit smaller under the stand for other equipment and have a way to load filter pad or socks in some way. Thinking about building a custom sump or insert in the stock tank for socks.

Display

Bare bottom with an insert this time. I love the look of sand, but hate the hassle and we want lots of random flow. I have 50# of Marco rock in the box that I'm going to start curing in a can with saltwater, power head and heater. I have another 30# in the sump and 80# I bleached recently due to a rampant aiptasia issue. The plan is to keep the structure no greater than 50% the height of the tank. At 35" deep, we can keep the rock off the back wall and push water around and behind the structure with the MPs.

That's the plan so far. Still researching options on a few things while we wait for the tank. Open to suggestions!

-Doug

Background

When we built our house ~15 years ago, we found a floor plan that was great for an in-wall. The garage had a double deep bay that backed up to the family room and would become a storage and support room. My wife and I spent an entire afternoon with a tape measure and painters tape mocking up what the wall would look like with a tank framed into it. We had two dedicated breakers wired to opposite sides of the tank to create redundancy and split the life support systems. Miracles built a great tank for us and the tank was wet within a week of moving into the house.

Fast forward 15 years; the closed loop is gone, we've gone through multiple generations of lighting from MH/VHO to Kessils/VHO, back to MH w/T5 and to XR30 G4 Pros and T5s. The tank had had it's good years and bad. There were a number of years where I was traveling internationally for work a lot and while I could monitor the tank with our Neptune, it was rough and over time we lost most of the SPS and the tank became host to some simpler corals, RBTAs that have split too many time and clowns.

It was time to drain the tank and start fresh, but if we were going that far, it didn't make sense to keep the tank as-is. Most recommend to strip and re-seal after 10-15yrs and while everyones mileage can vary, I didn't want to rebuild everything just to have problems down the road and wish I had cut the tank apart and rebuilt. Our first thought was, let's try acrylic. It's lighter, easy to get, doesn't have a history of catastrophic seam failures and we could make a few changes from the original design. After some soul searching, I couldn't pull the trigger on acrylic. I think back to all the times of going after the front glass with a razor blade and acrylic wasn't going to support my maintenance habits. Our local fish/coral shop begged me not to do acrylic and knowing my "retentive" habits, threatened to take me out on their maintenance runs in the valley to see what Acrylic scratches looked like and if I could live with it. I know LOTS of people on this board and others are very successful with acrylic and I don't want this to be a flame fest on the virtues of Acrylic versus Glass.

The Future

So glass it is. I checked around to see who the glass builders of the day were (insert 15yr gap) and while there are a few new ones out there, most didn't return emails or calls with the exception of Miracles. Derek emailed me back within hours and we started talking about the old tank and what we would do differently this time. Turns out, the guys on the floor remembered the original tank and offered a few suggestions. Drawings were exchanged and we got in the build queue. Tank ordered 4/30 and we are looking at about 9-weeks given their current backlog. We extended the depth and removed all of the closed loop features from the first tank. I seriously looked at making the tank wider and taller, but it would have been a MAJOR hassle and required some extensive work to the wall.

About the only thing I didn't like about the original tank was the way we did the overflow. An acrylic sheet with teeth was added to the back of the tank. Over the years, the acrylic started to buckle and I was concerned it was putting stress on the vertical seams in the back of the tank. A couple of the teeth had broken over time too. For the overflow this time, we are going with a 20" EMS from Taylor.

Equipment List (Some new, some reused)

Miracles Aquariums custom in-wall tank

Exotic Marine Systems overflow

Apex Classic

Return #1 | Neptune Core 15 w/Arctica Chiller

Return #2 | Neptune Core-15 w/Pentair 80w UV

MRC Dual Beckett simmer w/Pan World 150PS and automated neck cleaner

Clear Water CW-200

3ea Radion XR30-G4 Pro LED w/diffusers

4ea 54W ATI Blue-Plus T5 (0-10v controlled)

4ea Vortech MP-40s

DIY Auto-Top off

Neptune DOS for automated water changes

GHL Doser2 (Alk/Kalk/Mg)

Sump

Sump is currently a rubbermaid 100g stock tank. It works well for storing extra rock and system volume, but I'd like like it to be a bit smaller under the stand for other equipment and have a way to load filter pad or socks in some way. Thinking about building a custom sump or insert in the stock tank for socks.

Display

Bare bottom with an insert this time. I love the look of sand, but hate the hassle and we want lots of random flow. I have 50# of Marco rock in the box that I'm going to start curing in a can with saltwater, power head and heater. I have another 30# in the sump and 80# I bleached recently due to a rampant aiptasia issue. The plan is to keep the structure no greater than 50% the height of the tank. At 35" deep, we can keep the rock off the back wall and push water around and behind the structure with the MPs.

That's the plan so far. Still researching options on a few things while we wait for the tank. Open to suggestions!

-Doug