I knew I'd be going slow, but I never imagined this slow.

One might imagine by this point in time i'd have the tank set up, some inhabitants to care for, and I'd be overthinking whether or not I was feeding to much, providing enough light, etc...

Well I'm not quite there yet. I did tear up some carpet and make some probably ill-advised home modifications though! Behold, the tank pad!

I didn't want to place the tank on the carpet, nor did I want to replace the carpet yet (even though it's in pretty bad shape), so I decided to make this little tiled pad to put the tank on, allowing me to further postpone the decision to replace the carpet.

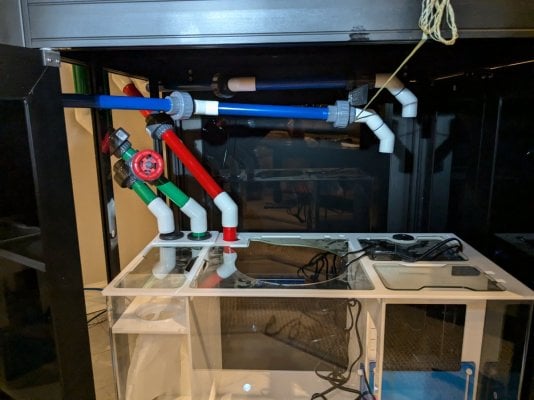

Also, not pictured here, I've hung my lighting, and have got a PVC pipe sticking up through the floor (and routed 25' across the basement inside a support beam) as a conduit for my water change and ato supply tubing! Just trying to figure out and test if I can get the apex to dos comms running over a cat5 cable w/ USB on the ends before that piece of the system is more or less complete.

So, it's getting there, slowly and painfully, it's getting there. I think I'll be ready in oh, 3-4 years at this rate .

Thanks for reading!!

One might imagine by this point in time i'd have the tank set up, some inhabitants to care for, and I'd be overthinking whether or not I was feeding to much, providing enough light, etc...

Well I'm not quite there yet. I did tear up some carpet and make some probably ill-advised home modifications though! Behold, the tank pad!

I didn't want to place the tank on the carpet, nor did I want to replace the carpet yet (even though it's in pretty bad shape), so I decided to make this little tiled pad to put the tank on, allowing me to further postpone the decision to replace the carpet.

Also, not pictured here, I've hung my lighting, and have got a PVC pipe sticking up through the floor (and routed 25' across the basement inside a support beam) as a conduit for my water change and ato supply tubing! Just trying to figure out and test if I can get the apex to dos comms running over a cat5 cable w/ USB on the ends before that piece of the system is more or less complete.

So, it's getting there, slowly and painfully, it's getting there. I think I'll be ready in oh, 3-4 years at this rate .

Thanks for reading!!