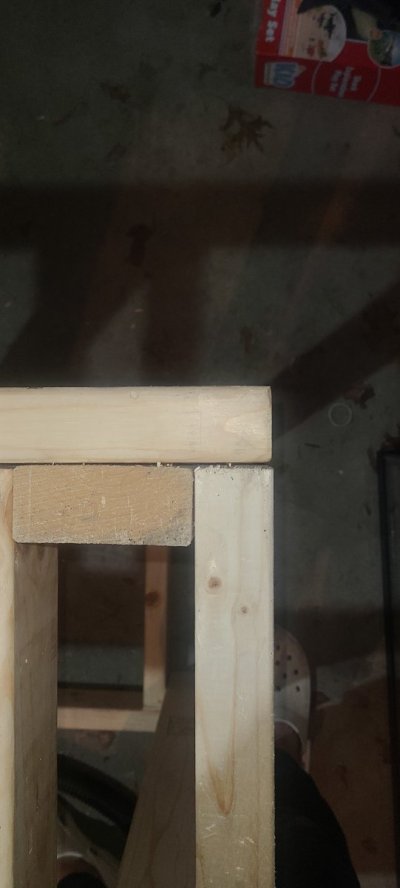

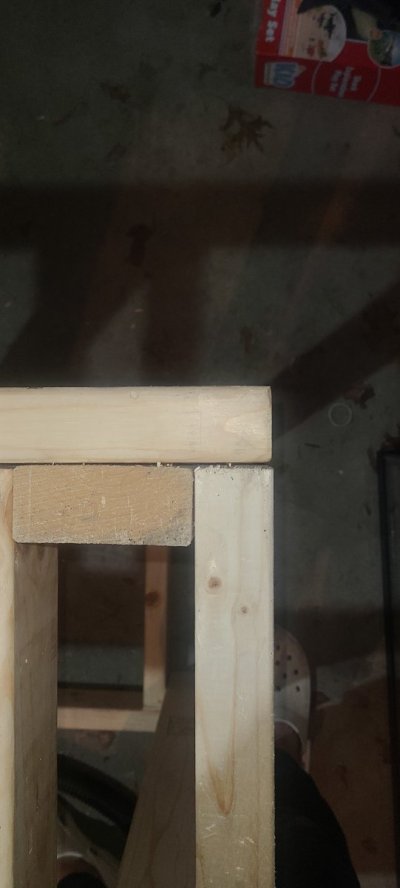

Hey all, so I'm about halfway through my 2x4 tank stand project (40'L x 20'W x 36"H) and I'm noticing that the wood is bowing on the length-wise pieces, causing an unlevel surface and gaps in the corner joints (see attached pics). My main question is: Is this even salvageable? And if so, how? I just dont want to come home one day to a collapsed stand and water everywhere.

Before you start roasting my carpentry skills, this IS my first diy tank stand (or anything with wood for that matter)

Before you start roasting my carpentry skills, this IS my first diy tank stand (or anything with wood for that matter)