So I played around like a cat with a ball of string. I checked the saddle clamp to ensure it was punctured cleanly which it was. See picture below.

I also double checked ALL lines.

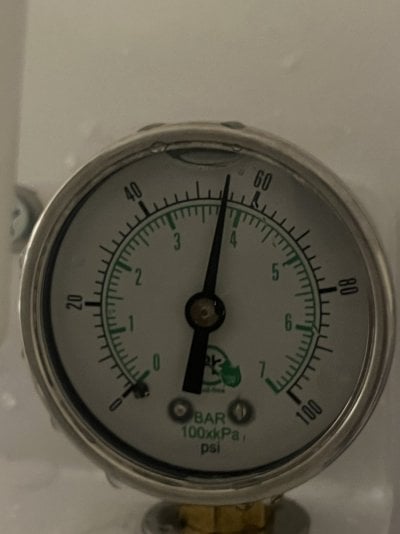

Right after the RO system and pressure gauge, I added a ball valve to stop flow. Miraculously I was getting approximately 58 PSI. When I turned on the system it went to absolutely zero even after bypassing the membranes, flush valve, and Auto Shutoff Valve. With the mentioned above it would still show zero.

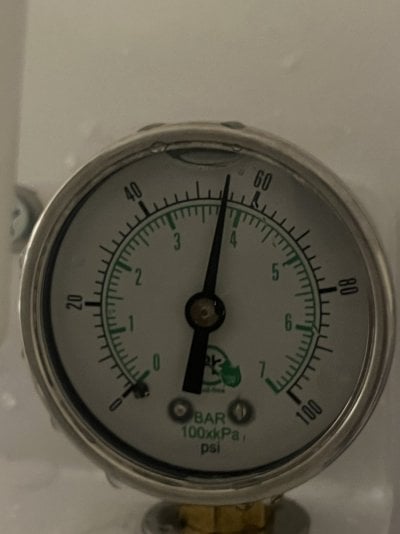

I put all the systems back together and got the same results before. 20 psi stationary and 22-24 psi with booster pump on.

I also double checked ALL lines.

Right after the RO system and pressure gauge, I added a ball valve to stop flow. Miraculously I was getting approximately 58 PSI. When I turned on the system it went to absolutely zero even after bypassing the membranes, flush valve, and Auto Shutoff Valve. With the mentioned above it would still show zero.

I put all the systems back together and got the same results before. 20 psi stationary and 22-24 psi with booster pump on.