Something to think about is how tall the stand will be will determine how many 2x4’s you will need to support your stand. The shorter the upright 2x4 the more weight it can hold if mounted correctly to another board, solid surface, etc… 2- 2x4’s on all 4 corners in an L shape would support your tank and instead of putting a 2x4 in the middle of the front and back I would put 45degree corner bracings on each of the 4 legs for access to a sump incase you use one. Stand could be built under $150 even at today’s crazy prices on wood. Standard pine would support the weight. And oh btw, most 2x4 built stands for tanks are over built anyways so don’t worry if the stand can hold the weight but rather worry and take great care to make it level by it being squarely built. I build all my stands out of 2x4s. Paint or water seal the would for stands that’ll last generations

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aquarium stand wood type

- Thread starter valley

- Start date

- Tagged users None

If you aren’t going marine those screws would be fine. I put titanium screws in the inside of my stand where humidity will be high. Titanium won’t rust and cause issues with potential poisoning your water if a screw takes a dip in the tank without you knowingThank you so much for this help! This has really answered all my questions regarding the wood. Just for confirmation, are these the 2x4’s you’re referring to?

2 in. x 4 in. x 96 in. Premium Burrill Fir Stud 1000020053 - The Home Depot

Burrill branded studs are the Pro's choice when it comes to 2 in. x 4 in. x 96 in. Studs. Visibly pleasing to the eye, Burrill branded end markings for easy identification stand for a super-premium gradedwww.homedepot.com

Also, these are the screws I’ll be using:

Grip-Rite #8 x 2-1/2 in. #2 Phillips Bugle Head Coarse Thread Wood Screws 5 lb. Box 212GS5 - The Home Depot

Grip-Rite 212GS5 #8 x 2-1/2 in. #2 Phillips Bugle Head Coarse Thread Wood Screws feature a sharp point which makes driving fast and efficient. Designed for interior, wood to wood applications, the coarsewww.homedepot.com

Regarding the wood glue, how would I use it? Do i just put it in between the 2x4 pieces so both the glue and the screws work to bring the pieces together?

- Joined

- Dec 8, 2017

- Messages

- 2,200

- Reaction score

- 4,115

Good advice!Something to think about is how tall the stand will be will determine how many 2x4’s you will need to support your stand. The shorter the upright 2x4 the more weight it can hold if mounted correctly to another board, solid surface, etc… 2- 2x4’s on all 4 corners in an L shape would support your tank and instead of putting a 2x4 in the middle of the front and back I would put 45degree corner bracings on each of the 4 legs for access to a sump incase you use one. Stand could be built under $150 even at today’s crazy prices on wood. Standard pine would support the weight. And oh btw, most 2x4 built stands for tanks are over built anyways so don’t worry if the stand can hold the weight but rather worry and take great care to make it level by it being squarely built. I build all my stands out of 2x4s. Paint or water seal the would for stands that’ll last generations

No problem, happy to help!Thank you so much for this help! This has really answered all my questions regarding the wood. Just for confirmation, are these the 2x4’s you’re referring to?

2 in. x 4 in. x 96 in. Premium Burrill Fir Stud 1000020053 - The Home Depot

Burrill branded studs are the Pro's choice when it comes to 2 in. x 4 in. x 96 in. Studs. Visibly pleasing to the eye, Burrill branded end markings for easy identification stand for a super-premium gradedwww.homedepot.com

Also, these are the screws I’ll be using:

Grip-Rite #8 x 2-1/2 in. #2 Phillips Bugle Head Coarse Thread Wood Screws 5 lb. Box 212GS5 - The Home Depot

Grip-Rite 212GS5 #8 x 2-1/2 in. #2 Phillips Bugle Head Coarse Thread Wood Screws feature a sharp point which makes driving fast and efficient. Designed for interior, wood to wood applications, the coarsewww.homedepot.com

Regarding the wood glue, how would I use it? Do i just put it in between the 2x4 pieces so both the glue and the screws work to bring the pieces together?

I'm not familiar with those 2x4's, but if they look straight and you like them, go for it. I personally have used these before, just try to get the straight, nice ones:

https://www.homedepot.com/p/2-in-x-4-in-x-8-ft-Prime-Stud-058449/312528776

You'd probably be fine with those screws. I might suggest an exterior screw or even a deck screw, which would give you more resistance to corrosion than a regular wood screws. Maybe something like these:

https://www.homedepot.com/p/DECKMAT...Deck-Screw-1-lb-Box-87-Piece-115923/313358323

For the wood glue, yep! Spread a nice layer between the wood where the two pieces of wood are in contact, then drive your screws right through both pieces of wood. When the glue dries, you could *practically* remove all the screws and the glue would probably still hold the stand together. The glue makes a very, very strong joint. For the glue, look for TiteBond II (water resistant), TiteBond III (waterproof), or Gorilla Glue has a wood glue at Home Depot too.

And as for having the employees at Home Depot cut your lumber, they will do it, but admittedly some of them begrudgingly. People are people, some are more willing to help you and are better at working the saws, some employees don't want to help you and/or don't know how to run the saw. Try to find one of the better employees and have them take some time to get your cuts right. Definitely make sure the vertical pieces that are really what's supporting the weight of the tank are all cut to the same length. Home Depot should be able to do that for you.

Or, if you can't or don't want to rely on Home Depot to cut your wood, if you can beg or borrow even a small miter saw, you could make all your own cuts really easily (at least for your 2x4's, not so much your plywood, but the 2x4's are most important for stability). Maybe ask a family member, friend or neighbor if they have a miter saw you could borrow, or if they would even help you with your build. Even if you can find a circular saw or jig saw there are tricks and tips to get nice, straight cuts with these simple hand saws.

I hope this is helpful, please let us know if you have any more questions!

Last edited:

- Joined

- Dec 8, 2017

- Messages

- 2,200

- Reaction score

- 4,115

Nice looking stand, thanks for posting!As long as you use good paint (I used a cabinet grade paint which is super durable and has a little oil in it) I think you are safe to go with regular 2x4s and wrap everything with 3/4” birch plywood or poplar. It gives the smooth and nice looking finish. It all depends on how well you seal your lumber inside and out.

I’ve been struggling to find some pics of anything I’ve done, just so you know I’m not just making this stuff up ;-)

Here’s a rack I put together very recently. This is NOT the best or strongest design, but I built this because I needed something fast and temporary for a QT system and at the time I was trying to help another R2R member build a simple stand with little experience or tools, and this is just about the easiest design I could think of. A lot of people gave me flack for suggesting this design, but I’m just showing what I did and it’s been holding three 10’s and a 20 long for about 3 months without the slightest sign of failure or sagging. No plywood top, no side skins, and no wood glue. I don’t recommend any of that, just showing what’s possible. If you do add the top, sides and glue, a stand like this would be rock solid for years, and plenty strong for your 60 gallon, no doubt at all.

This one is older now and was just supposed to be a prototype of sorts, I have always wanted to rebuild this design with nicer wood. This stand is for an IM Fusion 15 freshwater and is made from nothing but cheap 2x4’s and that Radiata pine plywood I mentioned in a previous post. I do have woodworking machines that can clean up and straighten the 2x4’s so they look a little nicer than off the shelf, but same stuff as the rack above.

- Joined

- Sep 3, 2019

- Messages

- 999

- Reaction score

- 1,091

Someone pinged me but TL: DR.

Here is the basic design I’ve been showing for a long time. The green boards are optional if you know how to join boards. I would avoid pressure treated and metal brackets. Treated boards near reef critters sounds like a bad idea and metal and saltwater tends to rust.

Regarding boards: take the time and hunt for the good ones. Look in the other aisles as they tend to hide the nicer stuff from the framing section. Be picky.

Other than that, decent deck screws to hold it together, maybe some glue at the joints and you should be good.

Here is the basic design I’ve been showing for a long time. The green boards are optional if you know how to join boards. I would avoid pressure treated and metal brackets. Treated boards near reef critters sounds like a bad idea and metal and saltwater tends to rust.

Regarding boards: take the time and hunt for the good ones. Look in the other aisles as they tend to hide the nicer stuff from the framing section. Be picky.

Other than that, decent deck screws to hold it together, maybe some glue at the joints and you should be good.

General comments:

1. Home Depot/Lowes/etc are selling 2x4 for framing a house, not precision joinery. You’ll get imperfections in the pieces because that’s what the grade of wood for this purpose has.

2. You really want a saw to cut the wood yourself. These stores are, as noted above, selling for construction purposes, not joinery. The precision flatly won’t be there. If you want precision cut pieces you’re looking at 10x the cost.

3. However you build/cut the pieces you’ll want to allow for shims of some sort, because there’s almost no chance your floor is as flat as your tank.

4. Be very careful about middle supports. Many of these tanks are designed to span from one end to the other, if you have a middle support and it’s very slightly above the end ones - we’re talking 1/64 inch or less here, and all the load will go through that and the tank will span the opposite way it’s designed. Additionally - you need all six support points to be aligned and active. Four is easy enough - any three exist in the same plane as each other, leaving you to shim and adjust one to bring it to the exact same plane. If you have six support points (four corners and two mid-span) you’re making a lot more work for yourself to get all six points aligned to very high precision as only three start out inherently in the same plane.

1. Home Depot/Lowes/etc are selling 2x4 for framing a house, not precision joinery. You’ll get imperfections in the pieces because that’s what the grade of wood for this purpose has.

2. You really want a saw to cut the wood yourself. These stores are, as noted above, selling for construction purposes, not joinery. The precision flatly won’t be there. If you want precision cut pieces you’re looking at 10x the cost.

3. However you build/cut the pieces you’ll want to allow for shims of some sort, because there’s almost no chance your floor is as flat as your tank.

4. Be very careful about middle supports. Many of these tanks are designed to span from one end to the other, if you have a middle support and it’s very slightly above the end ones - we’re talking 1/64 inch or less here, and all the load will go through that and the tank will span the opposite way it’s designed. Additionally - you need all six support points to be aligned and active. Four is easy enough - any three exist in the same plane as each other, leaving you to shim and adjust one to bring it to the exact same plane. If you have six support points (four corners and two mid-span) you’re making a lot more work for yourself to get all six points aligned to very high precision as only three start out inherently in the same plane.

Alright thank you all for the help. I think I’ll be going to a lumberyard instead of a Home Depot for my wood. I contacted this lumeryard I found online and they said they’ll be able to cut the wood I buy for me. I’ll be buying any wood species that isn’t pressure treated and isn’t wet like hemlock for my 2x4’s. On second thought, I won’t be wrapping my entire stand. Considering the way I plan on positioning the stand, I think it’ll actually look better if it wasn’t wrapped. I’ll still be putting plywood on top though, and for that I’ll get anything that isn’t treated and is 1/2” or 3/4” thick. I’ll use shims to level the stand and use those deckmate screws alongside wood glue to build the stand. I’ll also be sure to take all the advice I’ve been given into account. As for paint, I’m not sure which paint I’ll use. Does anyone have any recommendations?

Alright thank you all for the help. I think I’ll be going to a lumberyard instead of a Home Depot for my wood. I contacted this lumeryard I found online and they said they’ll be able to cut the wood I buy for me. I’ll be buying any wood species that isn’t pressure treated and isn’t wet like hemlock for my 2x4’s. On second thought, I won’t be wrapping my entire stand. Considering the way I plan on positioning the stand, I think it’ll actually look better if it wasn’t wrapped. I’ll still be putting plywood on top though, and for that I’ll get anything that isn’t treated and is 1/2” or 3/4” thick. I’ll use shims to level the stand and use those deckmate screws alongside wood glue to build the stand. I’ll also be sure to take all the advice I’ve been given into account. As for paint, I’m not sure which paint I’ll use. Does anyone have any recommendations?

Also, wood moves, it just does. You could buy a crappy 2x4 from Home Depot or you could go to a real hardwood lumber store and pay big money for a stick of exotic hardwood, and when you get it home it can and will move. Wood reacts to changes in temperature and humidity and will warp, twist, and cup, and often quickly. For 2x4's specifically, drier wood will move less, so that's why I suggested looking for kiln dried wood in my last post.

Look at the giant stacks of 2x4's on the upper racks at Home Depot, and notice how they are all nylon banded together at the ends. The boards in these stacks stay relatively straight and true. Then look at the pile where those nylon bands have been cut and the boards have been moved and picked through by customers. Look at how many of those boards are now so warped they would make a good hockey stick. Once those bands are cut, the boards can and will move freely on their own.

Typically, it's advised to buy your rough cut lumber and let it acclimate to your house for weeks to months, then mill and cut it to size for your project. Of course, no one building an aquarium stand has that kind of patients for wood to acclimate lol! So my advice would be to choose the straightest 2x4's you can find, and when you get them home stack them with some weight on them to hold them together. Try to emulate the stacks all banded together like I mentioned in the last paragraph, which prevents warping. Try not to leave them loose where they can more easily warp. Don't cut them to size and let them hang around you shop, cut them and then screw the parts together. Try to build the frame in one afternoon so once altogether it will resist individual pieces warping.

Use both screws and a good wood glue, the glue will make the stand rock solid. And predill your screw holes, it will make things much easier and prevents splitting your wooden pieces. I like Spax brand screws, though my Home Depot no longer sells them (My Lowes does have them). Any good exterior screw will work, deck screws would be a good choice. #8 or #10 (or the equivalent in a deck screw), and 2.5" long. should do it. Counter sink the screw heads just bellow the surface of the 2x4's so the screw heads don't interfere with your plywood skin.

If you put your stand together correctly and come back the next day and it seems a little wobbly because your 2x4's moved around a little, don't panic. Put some weight on it. Put your tank on it and fill the tank just a little bit and let it sit overnight again. This will force everything down and level out your stand.

Good luck and let us know how it turns out!

Attachments

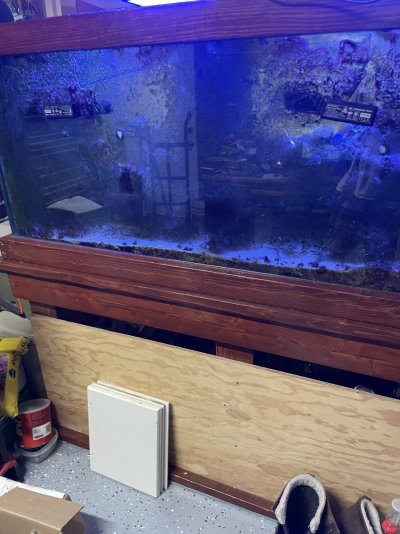

These are what I use for a stand

This aquarium has Been running for 12 plus years

We used 2x6 from home Creepo and it worked great

Had an earthquake 4 years ago and had to brace it with the plywood that is not stained .

The tank is 36”height

36” deep

72” long

This aquarium has Been running for 12 plus years

We used 2x6 from home Creepo and it worked great

Had an earthquake 4 years ago and had to brace it with the plywood that is not stained .

The tank is 36”height

36” deep

72” long

Totally overkill, but I use 4x4 posts joined with 2x4 and 2x6 and wrapped with rift sawn oak (wife wanted it to match other furniture). Just be sure to make everything square. I opted for drawers under as sump and equipment are in “fish room” under the staircase. Still need to add trim pieces at top and bottom.

If my memory serves me correctly, Tidal Gardens used to have a lot of their tanks supported just on the ends with cinder blocks with nothing spanning between them. It’s important as you said that anything in the middle is even or slightly lower to prevent a high point.4. Be very careful about middle supports. Many of these tanks are designed to span from one end to the other, if you have a middle support and it’s very slightly above the end ones - we’re talking 1/64 inch or less here, and all the load will go through that and the tank will span the opposite way it’s designed. Additionally - you need all six support points to be aligned and active. Four is easy enough - any three exist in the same plane as each other, leaving you to shim and adjust one to bring it to the exact same plane. If you have six support points (four corners and two mid-span) you’re making a lot more work for yourself to get all six points aligned to very high precision as only three start out inherently in the same plane.

When you take a look at paint, make sure you get a good quality primer. The paint is only there to give it color, it’s actually the primer that gives you the protection. I know a lot of people like using the Kilz primer. I’m fond of Benjamin Moore’s Fresh Start High Hiding primer. It goes on nice and thick and seals well. But any good latex primer will work.Alright thank you all for the help. I think I’ll be going to a lumberyard instead of a Home Depot for my wood. I contacted this lumeryard I found online and they said they’ll be able to cut the wood I buy for me. I’ll be buying any wood species that isn’t pressure treated and isn’t wet like hemlock for my 2x4’s. On second thought, I won’t be wrapping my entire stand. Considering the way I plan on positioning the stand, I think it’ll actually look better if it wasn’t wrapped. I’ll still be putting plywood on top though, and for that I’ll get anything that isn’t treated and is 1/2” or 3/4” thick. I’ll use shims to level the stand and use those deckmate screws alongside wood glue to build the stand. I’ll also be sure to take all the advice I’ve been given into account. As for paint, I’m not sure which paint I’ll use. Does anyone have any recommendations?

- Joined

- Dec 8, 2017

- Messages

- 2,200

- Reaction score

- 4,115

With standard rimmed/framed tanks, like the OP has, you can support them from either the ends or across the two long sides. The frame adds a lot of strength.If my memory serves me correctly, Tidal Gardens used to have a lot of their tanks supported just on the ends with cinder blocks with nothing spanning between them. It’s important as you said that anything in the middle is even or slightly lower to prevent a high point.

Clearly, you wouldn't want a "hump" in the middle of your frame's rail or crossmember, you do want to take some care and make sure all the vertical support pieces including any center supports are the same length, whether you cut your own or have Home Depot do it.

As said, you wouldn't want a hump in the center, but I don't really see that as a big concern here. The OP's tank is just 48" long, I don't see how they'd manage to fit a center support piece in place that would be so long that it would push the rail up in the middle.

To the OP, dry fit your pieces before assembling, meaning, you can drill and screw the frame pieces together to see if everything is coming together as you planned. If things are lining up and looking good, just back the screws out and reassemble everything with your wood glue.

And, something to keep in mind is that it's very important to make sure that all the vertical support pieces are cut to the same exact length, but it does not matter what length that is. What I mean is, if your stand plans called for the vertical pieces to be 30" long, for example, and you cut them to 29.75" or 30.125" it doesn't really matter as long as all the pieces are the same length. The only thing this will change is that your final stand will be a fraction of an inch higher or lower than you planned on paper. Not a big deal for most of us, unless you require an exact height.

My Home Depot has a good panel saw and a radial arm saw, and the radial arm saw has a stop block. Tell the person helping you that you really need at least the vertical pieces to be all the same. I would suggest you ask that they use the radial arm saw with a stop block, they should know how to set the stop block to whatever length you want, and then all the pieces should come out exactly the same length. It can also be done on the panel saw, so if the person is confident, I'd say go for it. It's only a 2x4, they have more of them ;-) Either way, have them slice one or two and then stop and check with your tape measure.

Whether or not Home Depot does a good job cutting your material really comes down to the person who happens to be helping you at Home Depot. I've had pretty good luck with them for the most part, so maybe give them a shot if you can't find your own saw to use. I mean, we are talking about a few bucks worth of 2x4's to try it, and if the Home Depot person really screws up, you don't have to buy the wood, they through it on their discount pile. Bring your own tape measure and double check what they are doing.

- Joined

- Dec 8, 2017

- Messages

- 2,200

- Reaction score

- 4,115

Another suggestion, I would buy, cut and assemble your 2x4 frame before buying (or at least cutting) your top, side skins and any trim material. As I was saying before, your 2x4 stand may for whatever reason come out slightly larger or smaller in some direction than you had planed on paper or in your head. Get your 2x4 frame going first, it's easily the most important part of your build, and once it's finished then cut your top and sides to fit your frame exactly.

Ok so I am a cabinet maker and most of what people are telling is true. 2x4 are great for fish tank stands. You do not need to skin it in ply wood all are true. I use desk screws for my stands. If you want to skin it Home depot sells cabinet grade plywood for like 65$. I would paint the bones of the cabinet with water blocking paint. You can get if from Home depot. If you want more help just let me know. Have fun building

What kind of paint do you recommend? I was looking at high gloss enamel.Ok so I am a cabinet maker and most of what people are telling is true. 2x4 are great for fish tank stands. You do not need to skin it in ply wood all are true. I use desk screws for my stands. If you want to skin it Home depot sells cabinet grade plywood for like 65$. I would paint the bones of the cabinet with water blocking paint. You can get if from Home depot. If you want more help just let me know. Have fun building

Ok for the inside ugly drylok this water proofs the in side form salt and water. The outside primer, sand it after it drys. Then urethane cabinet paint. I like Sherwin Williams or Benjamin Moore. Urethane wears like oil paints like water base. Cleanup is easy too. Keep in mind high gloss will show any little flaws with a spotlight. If your a highly detailed person it will drive you nuts. Do remember you can always sand it down and do it againWhat kind of paint do you recommend? I was looking at high gloss enamel.

Similar threads

- Replies

- 26

- Views

- 454

- Replies

- 7

- Views

- 188