- Joined

- Dec 23, 2019

- Messages

- 13

- Reaction score

- 19

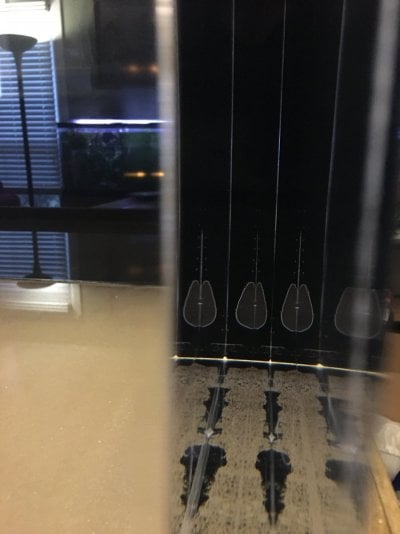

Thanks for all the replies! I hear you as far as the amount of work that it would take to remove those overflows, and likely the clairity wouldn't be up to my standard. I will just have to figure out how to make these two corner overflows work, my current tank is running a bean animal set up and I am very pleased with how quiet it is.