- Joined

- May 2, 2020

- Messages

- 116

- Reaction score

- 111

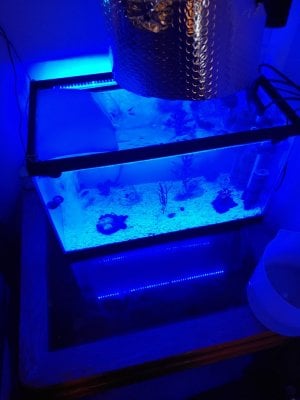

Hi all you fellow Reefers, My entry into this fine group was over my Dwarf Seahorse Breeding Pond. There are 750 gallons of Marine Ponds here. With two separate Breeding Corrals and perhaps 100 or so Ponies. It was time to share the methods. The marine ponds are a little too high in Phos for hard coral. The Gorgonia, ricordea, and Macro Algae do great as well as lots of great Frags. All Frags look drab in sunlight and there is so much Plankton that the water is golden green under UV at night. Any attempt to see the Colors Pop at night is stopped by the Green Glow of living water. I have no Reef Tank. I miss Hard Coral. The Reef Tank described below already works in all the ponds. Here is how to build the simplest, cheapest, and most effective system possible :>) Such a statement is only possible because there is no function left undone and no possible reduction in parts. There are two key points about the design and materials. The Bio Cloth must be HDPE Ribbon Knitted Shade Cloth. Only a Knitted Ribbon forms the low oxygen junctions that support Anaerobic Processes ( Nitrate removal ). Any old Bio Ball does aerobic ( ammonia/ nitrate ) breakdown. There is no low oxygen Depth to a plastic surface. The Foam Cores that are Not Used have never done Anaerobic and get loaded up. Winding new Bio Cloth Cores provides a semi permanent solution. The material is a course filter that does not load up ( good flow ). It has huge surface area for aerobic activity and all the plastic to plastic low oxygen zones for anaerobic.

The original Foam Units ( fresh water ) do not have a Protein Scrubber. To make a complete Marine System, the second Foam Unit is turned upside down and snapped onto the lower Filter Unit. It becomes a Protein Scrubber because a trimmed 5 ml Dropper is shoved up the upper tube ( picture makes clear ). It bypasses the foam from reentering the Bridge and forces all gack to leave by the now repurposed Air Ring in the upper unit.

As is seen the water being pumped up is not allowed to get back until it crosses the Bridge. The Air goes up and the Water goes across and down.

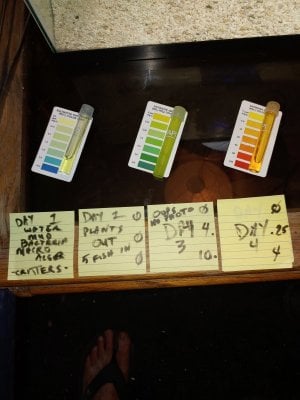

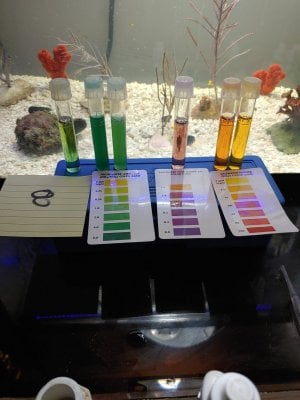

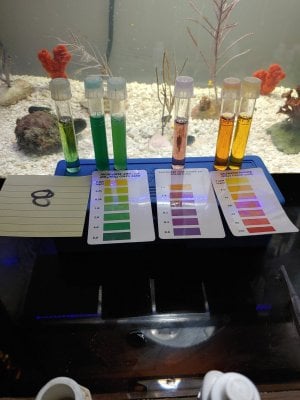

Control is achieved by one Air Valve. The System Picture shows the Air Stone glued down. It is the lowest Air Feature. The Air Lift Filter mounts are glued about 1 1/2 inches higher. The Air Valve only limits the Air to the Filter/Scimmer. At full Air to the Filter, the Air Stone is minimum and the Scimmer dumps 1 gpd. it is about 10 gph through the Filter when there is Air appearing in the Downspout. It is running at about 4 gph now and 1 cup per day Skim. It was started Saturday 6/20 with a commercial Bacteria load. It got two filtered mud dumps from the Main Pond bottom ( hydrogen sulfide type deep mud quickly transferred ) provide some living Low Oxygen Bacteria to get going. The Molly Crew was day two. They are my favorite crew and will stay after the Tank is seasoned. It takes one cap of Ammo Quell each Morning and Night for 5 days. The Bio Cloth colonizes much fast than Rock.

I included a picture of the Big Protein Cannon in the Main Pond. It dumps about 1 gpd. Behind are two 400 gph pond pumps wrapped in the magic cloth. Both the Ponds and the Reef Tank have no blades or larval hazards. All current is from Water Entry. The pumps are low suction on the surface as are the Bio Cores of the Tank System. I will post some better pictures if there is any interest. Lets test out the possibilities. This system makes quality Marine Systems possible for very low cost. It should support an interesting Reef Tank with lower Phos than possible in the Breeder Ponds. Happy Reefing

PS: the picture of the layout on the table shows the Dropper used and a second System for comparison with the installed unit.

The original Foam Units ( fresh water ) do not have a Protein Scrubber. To make a complete Marine System, the second Foam Unit is turned upside down and snapped onto the lower Filter Unit. It becomes a Protein Scrubber because a trimmed 5 ml Dropper is shoved up the upper tube ( picture makes clear ). It bypasses the foam from reentering the Bridge and forces all gack to leave by the now repurposed Air Ring in the upper unit.

As is seen the water being pumped up is not allowed to get back until it crosses the Bridge. The Air goes up and the Water goes across and down.

Control is achieved by one Air Valve. The System Picture shows the Air Stone glued down. It is the lowest Air Feature. The Air Lift Filter mounts are glued about 1 1/2 inches higher. The Air Valve only limits the Air to the Filter/Scimmer. At full Air to the Filter, the Air Stone is minimum and the Scimmer dumps 1 gpd. it is about 10 gph through the Filter when there is Air appearing in the Downspout. It is running at about 4 gph now and 1 cup per day Skim. It was started Saturday 6/20 with a commercial Bacteria load. It got two filtered mud dumps from the Main Pond bottom ( hydrogen sulfide type deep mud quickly transferred ) provide some living Low Oxygen Bacteria to get going. The Molly Crew was day two. They are my favorite crew and will stay after the Tank is seasoned. It takes one cap of Ammo Quell each Morning and Night for 5 days. The Bio Cloth colonizes much fast than Rock.

I included a picture of the Big Protein Cannon in the Main Pond. It dumps about 1 gpd. Behind are two 400 gph pond pumps wrapped in the magic cloth. Both the Ponds and the Reef Tank have no blades or larval hazards. All current is from Water Entry. The pumps are low suction on the surface as are the Bio Cores of the Tank System. I will post some better pictures if there is any interest. Lets test out the possibilities. This system makes quality Marine Systems possible for very low cost. It should support an interesting Reef Tank with lower Phos than possible in the Breeder Ponds. Happy Reefing

PS: the picture of the layout on the table shows the Dropper used and a second System for comparison with the installed unit.