- Joined

- Apr 2, 2018

- Messages

- 3

- Reaction score

- 2

Awesome build! I'm contemplating the same size tank as a peninsula from customaquariums. It's neat to follow your build. Keep up the good work!

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Awesome build! I'm contemplating the same size tank as a peninsula from customaquariums. It's neat to follow your build. Keep up the good work!

Nice build

Glad I am not the only one that has trouble with the colors on the test chartsTested my QT water. I think it's good. Test colors are hard to differentiate. But ammonia levels are low. Total ammonia is either 0 or 0.1ppm. My pH is 7.6 (lowest on chart). According to the Red Sea kit, my total toxic ammonia (meaning ammonia as opposed to ammonium if I understand correctly) is 0.0023 at most. Nitrites are near 0. Nitrates are somewhere between 2 and 5ppm.

With water parameters looking OK and recent WC, I've dosed half the Prazipro. I'll add the second half tonight I think.

EDIT: Does anyone know why these images keep attaching to my replies? I didn't add the image below to this post and in my edit, I can delete it but it doesn't delete in the posting... It just shows back up.

EDIT2: TY @NY_Caveman !!!

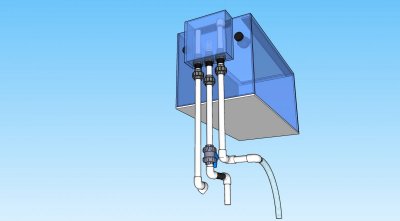

Gluing PVC in general can suck... But it especially sucks when dealing with two overflow boxes (i.e. two fixed positions) as to not strain the polycarbonate outputs. While I may be overly cautious or obsurd, one degree in an elbow angle and/or 1/16" in a run can make problems.

Plumbed my return today. Still gotta add the pump and paint the return manifold black.