I'm actually pretty annoyed with Sicce's unusual threading size on their pump.

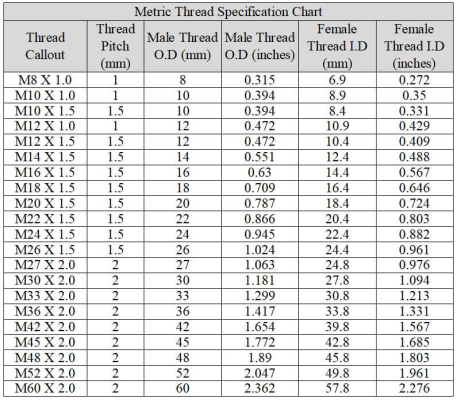

My current return line is plumbed for 1 1/4" to get maximum flow out of my waterbox 150.4 setup. It seems the Sicce 7 SDC pump has a thread around it sized for 1 3/8" which is unusual and quite questionable (why ‽).

I'm able to find reducers to go from 1" to 1 1/4" pretty easily -- matching the slip Sicce provides with their 1 3/8" thread, but this isn't what I want. I want to reduce from 1 3/4" to 1 1/4" and retain that flow as much as possible. Better yet, I'd love to use my existing 1 1/4" union attached to the COR 20 I'm removing and replace the end attaching it to my Sicce.

Does anyone know where I could get a threaded reducer fitting my needs?

My current return line is plumbed for 1 1/4" to get maximum flow out of my waterbox 150.4 setup. It seems the Sicce 7 SDC pump has a thread around it sized for 1 3/8" which is unusual and quite questionable (why ‽).

I'm able to find reducers to go from 1" to 1 1/4" pretty easily -- matching the slip Sicce provides with their 1 3/8" thread, but this isn't what I want. I want to reduce from 1 3/4" to 1 1/4" and retain that flow as much as possible. Better yet, I'd love to use my existing 1 1/4" union attached to the COR 20 I'm removing and replace the end attaching it to my Sicce.

Does anyone know where I could get a threaded reducer fitting my needs?