- Joined

- Nov 8, 2019

- Messages

- 27

- Reaction score

- 15

Looking for some help with my recently upgraded my RODI system. The info is below (poorly organized).

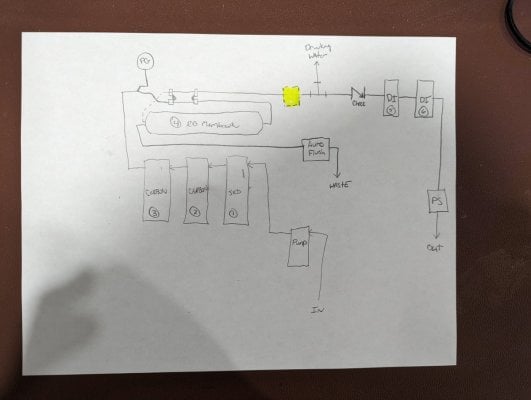

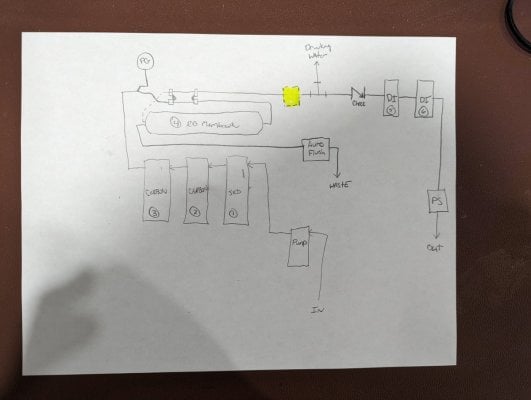

I started with an Icecap 4 stage. About a month ago I added a pump and pressure switch. Last week, I added a 2 stage DI and auto flush. The system doesn't seem to be working correctly. Attached is a diagram of how it is currently hooked up. In this configuration, the auto flush stays partially open when there is no demand for water (very slow waste water flow). I assume it shouldn't do that.

I initially wanted to put the pressure switch in the highlighted area so the pump is turns on when there is a demand for drinking water. However, when I had it there it turned on randomly. This happened before and after the auto flush valve was installed.

I should also mention that if I unplug the transformer and turn of the water supply to the unit, the pressure drops to zero over time. Shouldn't the system stay pressurized? Based on my limited knowledge of how these systems work, everything together points to a leak somewhere. I haven't seen any signs of a leak though.

Lastly, the RO doesn't seem to be performing as well as it should. I have approx. 100 TDS going in and it enters the DI at 13 TDS. The system is only 3 months old, so I would think the membrane should still be performing near spec (98% rejection rate).

Does anyone see anything incorrect with the configuration or have any suggestions?

I started with an Icecap 4 stage. About a month ago I added a pump and pressure switch. Last week, I added a 2 stage DI and auto flush. The system doesn't seem to be working correctly. Attached is a diagram of how it is currently hooked up. In this configuration, the auto flush stays partially open when there is no demand for water (very slow waste water flow). I assume it shouldn't do that.

I initially wanted to put the pressure switch in the highlighted area so the pump is turns on when there is a demand for drinking water. However, when I had it there it turned on randomly. This happened before and after the auto flush valve was installed.

I should also mention that if I unplug the transformer and turn of the water supply to the unit, the pressure drops to zero over time. Shouldn't the system stay pressurized? Based on my limited knowledge of how these systems work, everything together points to a leak somewhere. I haven't seen any signs of a leak though.

Lastly, the RO doesn't seem to be performing as well as it should. I have approx. 100 TDS going in and it enters the DI at 13 TDS. The system is only 3 months old, so I would think the membrane should still be performing near spec (98% rejection rate).

Does anyone see anything incorrect with the configuration or have any suggestions?