Great post. I have a Reefmat 500 and the drive unit would not rotate the spool one evening last week. No attempts or motor noise and a Jam message present in the app with a blinking alarm light on the drive unit itself were the observed symptoms. I tried a couple power resets and a 12 hour power down without any success. The unit has been working w/o issue for just over a year. I contacted RedSea and they quickly replied by email to offer sending a replacement motor. I was surprised they offer internal replacement parts for the drive unit, but the replacement was straight forward and simple to complete. No signs of moisture intrusion or burned components. The replacement motor resolved the concern.

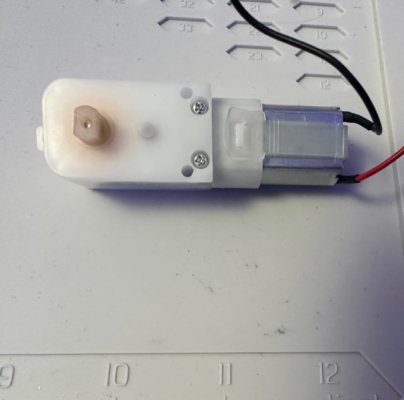

I was curious on what caused the failure. The drive motor (looks like a permanent magnet DC motor) is attached to a plastic gearbox. I removed the motor from the gearbox (held by a plastic strap) and the gearbox turned freely and smooth. Reduction ratio is likely pretty low as it's difficult to turn the output side when the motor is connected. I hooked the DC motor to my bench power supply @ 12.0V and tried a low amperage 1st 100 mA, no movement, 200 mA no movement, the motor finally turned at over 500 mA. After this initial power up, the motor would move @ 100 mA every time. Reinstalled the motor in the gearbox and put some good load on the output end w/o any large increases in amperage draw. I've put the old motor in the parts bin, but I suspect some brush issue?

Thanks for posting the info on the driver side. I'm curious if it uses the same PCB as the 1200. If I have to open the drive unit up again, I'll take some pictures.

I was curious on what caused the failure. The drive motor (looks like a permanent magnet DC motor) is attached to a plastic gearbox. I removed the motor from the gearbox (held by a plastic strap) and the gearbox turned freely and smooth. Reduction ratio is likely pretty low as it's difficult to turn the output side when the motor is connected. I hooked the DC motor to my bench power supply @ 12.0V and tried a low amperage 1st 100 mA, no movement, 200 mA no movement, the motor finally turned at over 500 mA. After this initial power up, the motor would move @ 100 mA every time. Reinstalled the motor in the gearbox and put some good load on the output end w/o any large increases in amperage draw. I've put the old motor in the parts bin, but I suspect some brush issue?

Thanks for posting the info on the driver side. I'm curious if it uses the same PCB as the 1200. If I have to open the drive unit up again, I'll take some pictures.