Hey R2R,

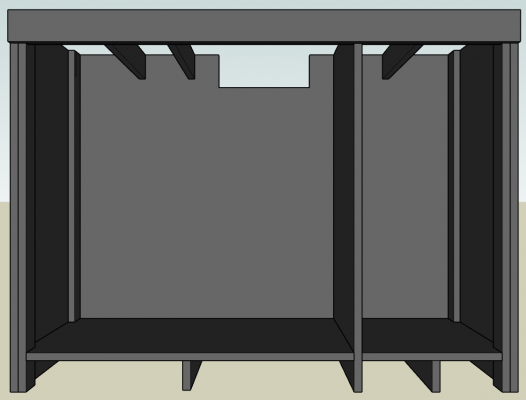

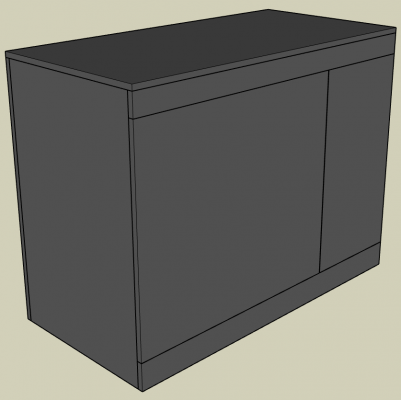

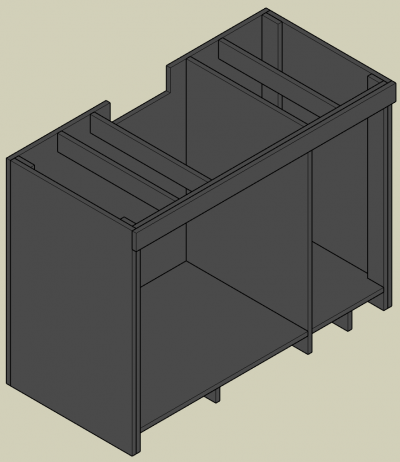

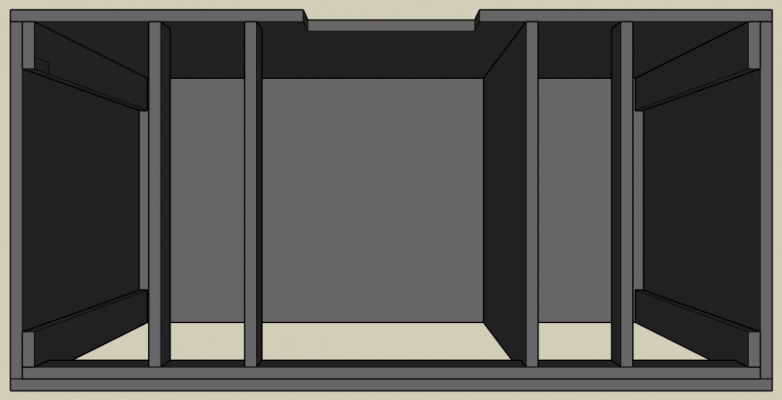

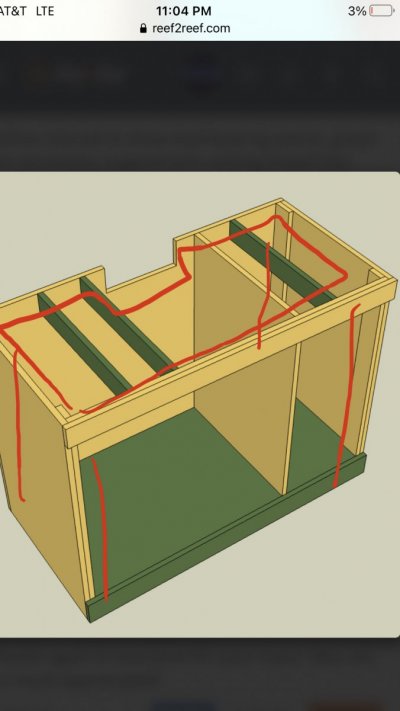

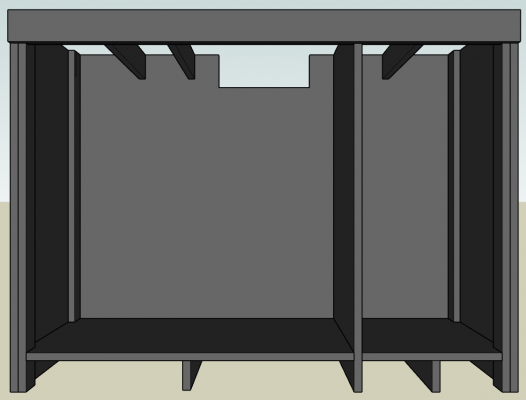

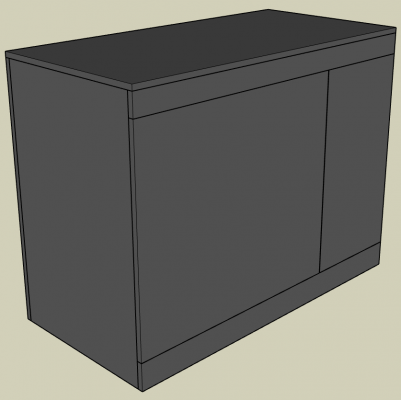

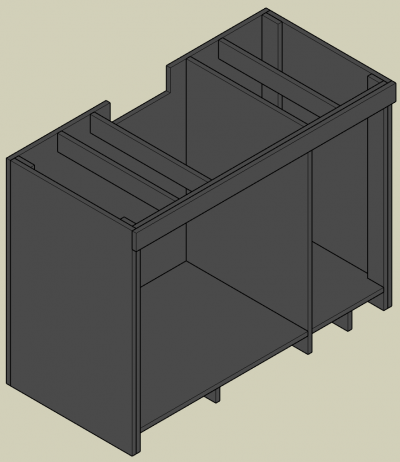

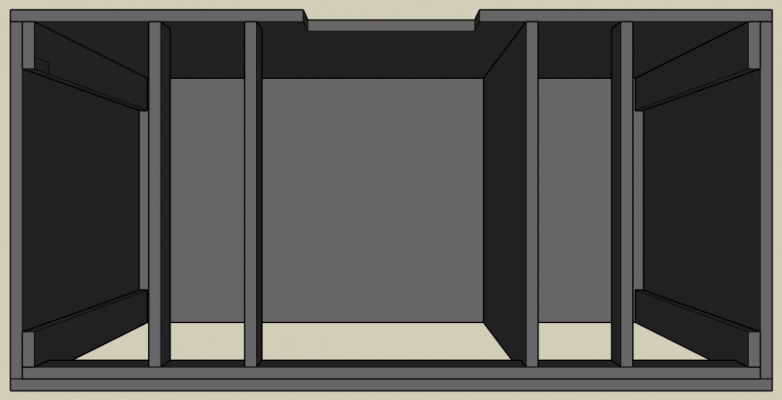

First post here (I think). I'm totally new to the saltwater world, and am looking to setup a SCA 120 gallon eurobraced tank. I'd like to tackle building the stand/cabinet myself, but I'm no woodworker. But, with a little help from a few friends, I think I can get it done.

Could someone more wise than myself look at my design and give me a go/no-go? All wood will be 3/4" birch (not Baltic probably, just the HD/Lowes 7 ply), Kreg Pocket screws w/ Titebond III, concealed euro-hinges with a 1.5" overlay.

Thanks!

First post here (I think). I'm totally new to the saltwater world, and am looking to setup a SCA 120 gallon eurobraced tank. I'd like to tackle building the stand/cabinet myself, but I'm no woodworker. But, with a little help from a few friends, I think I can get it done.

Could someone more wise than myself look at my design and give me a go/no-go? All wood will be 3/4" birch (not Baltic probably, just the HD/Lowes 7 ply), Kreg Pocket screws w/ Titebond III, concealed euro-hinges with a 1.5" overlay.

Thanks!