I didn’t make any kind of build thread when I first set up this tank in 2004, which I have regretted several times over the years when I try to recall something I did and can’t, or worse, remember it wrong! I decided a few months ago to move the sump and various support items from under the tank to the basement to give my knees and back a break. (It’s tough to get old!); so this thread is about the tank update/renovation relating to that move.

Current tank:

Background and Description: Tank is a custom 225 gallon that’s 72” x 30” x 24” tall. It sits in the corner of my family room between the fireplace and the front wall of the house. Overflow is in the back right corner and there’s a “dry box” next it on the right side that is essentially a closed loop for the chiller. The whole overflow is one of my regrets that I would do very differently now if I had it to do over. Tank is lit by three metal halide PFO fixtures, original, 250 watt DE with Ice Cap HQI ballasts, also original. I’ve resisted temptation to change them out but one of these days a ballast will fail and I’ll have to.

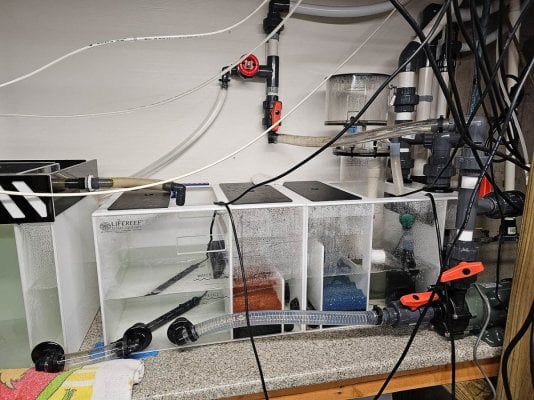

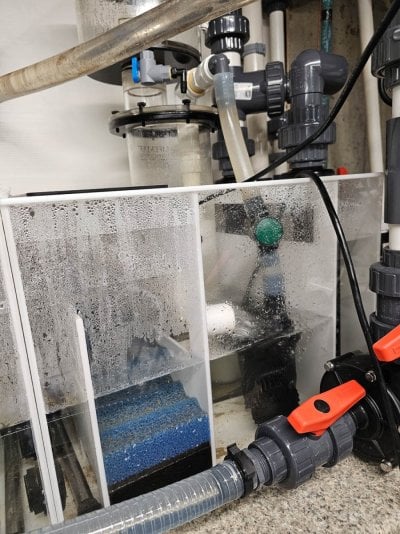

Sump is a LifeReef LF1-300 with the VS3-30 skimmer currently powered by a Sicce Syncra ADV 10. Since the sump is below the tank and tank is in the family room where we spend most of our time I was concerned about noise so the main system pumps are actually in the basement. Water flows from the tank to the sump, then from the sump through the floor to a counter in the basement right below the tank. Return is a Iwaki MD40RXT, original. I also had a closed loop running through the overflow to the basement then back to the top of the tank and split to multiple outlets via an Oceans Motion and powered by a Reeflo Barracuda, but that was dismantled years ago.

Sump is under tank (never looked this clean again):

Oceans Motion piping for closed loop:

Counter in basement showing original chiller, return pump and closed loop pump:

Current tank:

Background and Description: Tank is a custom 225 gallon that’s 72” x 30” x 24” tall. It sits in the corner of my family room between the fireplace and the front wall of the house. Overflow is in the back right corner and there’s a “dry box” next it on the right side that is essentially a closed loop for the chiller. The whole overflow is one of my regrets that I would do very differently now if I had it to do over. Tank is lit by three metal halide PFO fixtures, original, 250 watt DE with Ice Cap HQI ballasts, also original. I’ve resisted temptation to change them out but one of these days a ballast will fail and I’ll have to.

Sump is a LifeReef LF1-300 with the VS3-30 skimmer currently powered by a Sicce Syncra ADV 10. Since the sump is below the tank and tank is in the family room where we spend most of our time I was concerned about noise so the main system pumps are actually in the basement. Water flows from the tank to the sump, then from the sump through the floor to a counter in the basement right below the tank. Return is a Iwaki MD40RXT, original. I also had a closed loop running through the overflow to the basement then back to the top of the tank and split to multiple outlets via an Oceans Motion and powered by a Reeflo Barracuda, but that was dismantled years ago.

Sump is under tank (never looked this clean again):

Oceans Motion piping for closed loop:

Counter in basement showing original chiller, return pump and closed loop pump: