Hey there,

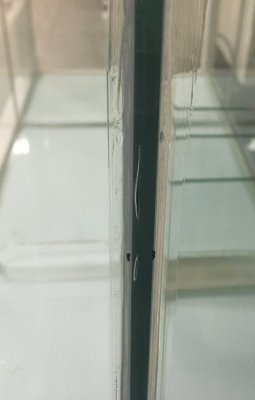

I need some advice on this stand (see picture) in terms of structure and long-term stability.

The steel frame is 49'' L x 21'' W x 39'' H. Each steel frame is about 1.6'' (4 cm) in thickness. I don't have any additional corner supports or vertical supports in the middle of the steel frame. Perhaps I should have requested these.

I've got a large sump ~50 galloons that will rest on 3/4'' plywood. The tank itself will rest on thick 1'' plywood. Plywood will be treated with Kilz and then a marine-grade white.

I need to do some research to find someone who can make magnetic panels. Enough DIY for me for a bit.

Any insights? Will this be a-ok from a structural perspective?

Cheers

I need some advice on this stand (see picture) in terms of structure and long-term stability.

The steel frame is 49'' L x 21'' W x 39'' H. Each steel frame is about 1.6'' (4 cm) in thickness. I don't have any additional corner supports or vertical supports in the middle of the steel frame. Perhaps I should have requested these.

I've got a large sump ~50 galloons that will rest on 3/4'' plywood. The tank itself will rest on thick 1'' plywood. Plywood will be treated with Kilz and then a marine-grade white.

I need to do some research to find someone who can make magnetic panels. Enough DIY for me for a bit.

Any insights? Will this be a-ok from a structural perspective?

Cheers