Hi folks.

Looking at trying to control an array of 6 xr15 knockoffs, actual brand name was 'intelligent ocean r80. Hoping to do so via pwm from my brand new robotank boards, (printing cases as I type!)

I'm from a software background, tiny bit of electronics knowledge but a lot to learn, hopefully this is the project to kick-start that.

First pic is the light with the cover off. To the left are the controller boards, wifi etc. My hope is actually to ditch all that as its interface is borderline unusable anyways. And instead just run a PWM signal to the two boards to the right of the heatsink that each supply four channels for the lights. Ultimately hoping to scrap the rest of the case etc and mount the led pucks, heatsink and boards into a custom low profile canopy that's being built.

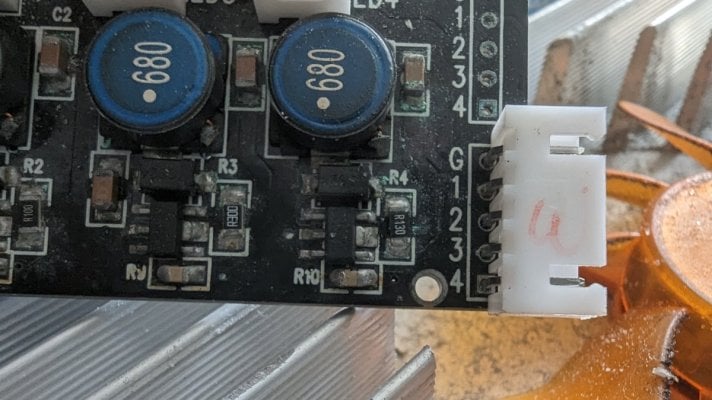

I've got my hands on an oscilloscope, although have next to no idea what I'm doing with it yet, and believe I'm picking up a pwm signal coming in via the headers circled below. It's definately a square wave pattern, but where I'm getting tripped up is that the pattern seems to be the same on each header, even when the channels are running at very different outputs.

The spec sheet I can find for the chip that I believe is doing to work here (mt7201 continuous mode stepdown driver, link below) seems to indicate the chip can be driven either by voltage or pwm.

I'm reading up on how to decipher the electronics ATM, but my hope is I can simply unplug the old control boards, and send a PWM signal from the robotank to each of these channels instead. If any kind soul with a better grasp of electronics than me want to say if that sounds like the right direction to go, or what I should be reading up on instead, I'd be extremely grateful.

Part two of this will then be, can I just daisy chain these lights with the pwm signal, or does something like that generally require a dedicated repeater/distribution board to split the signal between all lights?

Cheers folks!

https://www.google.com/url?sa=t&source=web&rct=j&url=https://pl-1.org/getproductfile.axd?id=13915&filename=MT7201.pdf&ved=2ahUKEwjS-4SQqoj8AhV-7zgGHXn-Df0QFnoECBEQAQ&usg=AOvVaw0rHK_6BVZ28gK8xxR4CjV9

Looking at trying to control an array of 6 xr15 knockoffs, actual brand name was 'intelligent ocean r80. Hoping to do so via pwm from my brand new robotank boards, (printing cases as I type!)

I'm from a software background, tiny bit of electronics knowledge but a lot to learn, hopefully this is the project to kick-start that.

First pic is the light with the cover off. To the left are the controller boards, wifi etc. My hope is actually to ditch all that as its interface is borderline unusable anyways. And instead just run a PWM signal to the two boards to the right of the heatsink that each supply four channels for the lights. Ultimately hoping to scrap the rest of the case etc and mount the led pucks, heatsink and boards into a custom low profile canopy that's being built.

I've got my hands on an oscilloscope, although have next to no idea what I'm doing with it yet, and believe I'm picking up a pwm signal coming in via the headers circled below. It's definately a square wave pattern, but where I'm getting tripped up is that the pattern seems to be the same on each header, even when the channels are running at very different outputs.

The spec sheet I can find for the chip that I believe is doing to work here (mt7201 continuous mode stepdown driver, link below) seems to indicate the chip can be driven either by voltage or pwm.

I'm reading up on how to decipher the electronics ATM, but my hope is I can simply unplug the old control boards, and send a PWM signal from the robotank to each of these channels instead. If any kind soul with a better grasp of electronics than me want to say if that sounds like the right direction to go, or what I should be reading up on instead, I'd be extremely grateful.

Part two of this will then be, can I just daisy chain these lights with the pwm signal, or does something like that generally require a dedicated repeater/distribution board to split the signal between all lights?

Cheers folks!

https://www.google.com/url?sa=t&source=web&rct=j&url=https://pl-1.org/getproductfile.axd?id=13915&filename=MT7201.pdf&ved=2ahUKEwjS-4SQqoj8AhV-7zgGHXn-Df0QFnoECBEQAQ&usg=AOvVaw0rHK_6BVZ28gK8xxR4CjV9

Last edited: