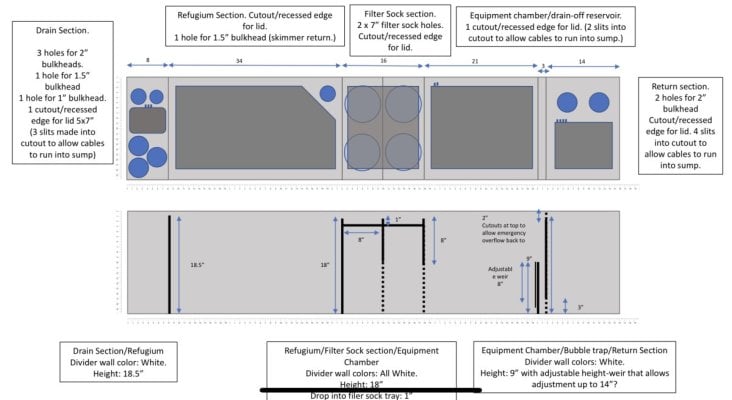

Well, this has been in the planning envisioning stages for about 10 years now, but it should soon be a reality… I hope

I started with a Biocube 29 in 2011, then moved up to a 180 gallon in 2013, moved to Colorado in 2017 and did a slight bump to a 220 gallon tank.

Recent 220G FTS:

I’m mostly focused on SPS and also like to take risks with non traditional reef safe fish, angels, butterflies, puffers.

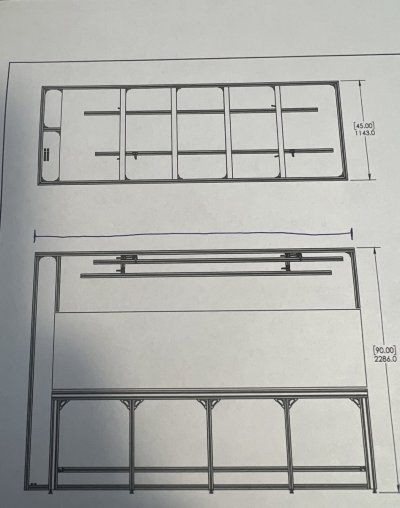

Anyway, this new build will be a 120”x45”x29” Peninsula build.

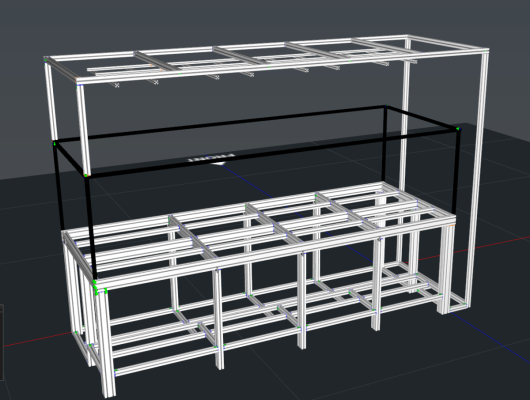

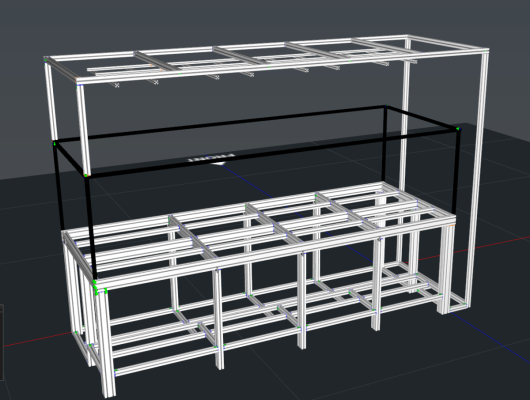

Here’s a rough 3D rendering I made up to give an idea of what I’m shooting for.

The first major obstacle I’ve had to overcome is that this is going to be placed in a finished basement, and there was absolutely no way to fit a 10’ tank, and a 10’ stand down the basement stairs .

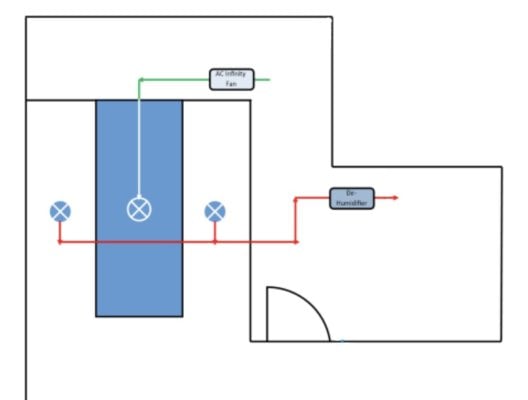

It will be positioned so it sticks out lengthways from the backwall into the room like below (before the basement was finished).

For the stand, it made sense to go with extruded aluminum, it would be easy to move into the basement and assemble on site. I used Controlled Dynamics to build my stand. Russ over there was amazing to work with and highly recommend him and the company/product if you are looking for a top quality stand.

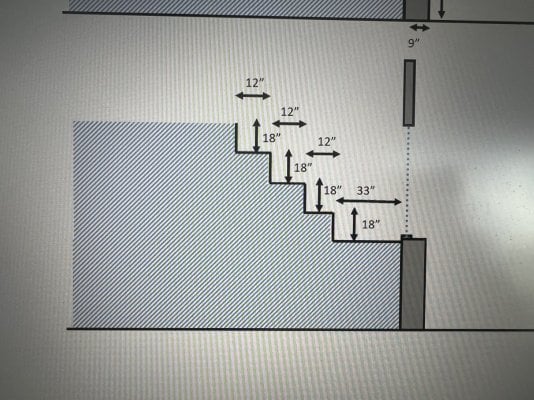

The next problem was how to get the tank down into the basement. I got quotes to build on site and it was about 3X the cost… so I wanted to avoid this. So.. I had an idea. Replace the window and window well in the basement with a French casement window and a terraced window well… managed to sell this idea to the wife, and we actually love the new look.. and it also now allows a 10’ fish tank to slide through the basement window (mathematically speaking).

Finished look.

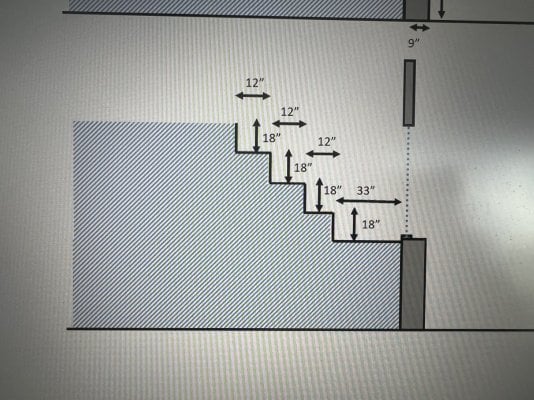

I did some math, and figured out what the levels of the window well needed to be.

I had a company come in and rip the old concrete window well out.

In went the Timbers

New Double French Casing window…

And the finished product

Will provide more updates soon.

I started with a Biocube 29 in 2011, then moved up to a 180 gallon in 2013, moved to Colorado in 2017 and did a slight bump to a 220 gallon tank.

Recent 220G FTS:

I’m mostly focused on SPS and also like to take risks with non traditional reef safe fish, angels, butterflies, puffers.

Anyway, this new build will be a 120”x45”x29” Peninsula build.

Here’s a rough 3D rendering I made up to give an idea of what I’m shooting for.

The first major obstacle I’ve had to overcome is that this is going to be placed in a finished basement, and there was absolutely no way to fit a 10’ tank, and a 10’ stand down the basement stairs .

It will be positioned so it sticks out lengthways from the backwall into the room like below (before the basement was finished).

For the stand, it made sense to go with extruded aluminum, it would be easy to move into the basement and assemble on site. I used Controlled Dynamics to build my stand. Russ over there was amazing to work with and highly recommend him and the company/product if you are looking for a top quality stand.

The next problem was how to get the tank down into the basement. I got quotes to build on site and it was about 3X the cost… so I wanted to avoid this. So.. I had an idea. Replace the window and window well in the basement with a French casement window and a terraced window well… managed to sell this idea to the wife, and we actually love the new look.. and it also now allows a 10’ fish tank to slide through the basement window (mathematically speaking).

Finished look.

I did some math, and figured out what the levels of the window well needed to be.

I had a company come in and rip the old concrete window well out.

In went the Timbers

New Double French Casing window…

And the finished product

Will provide more updates soon.