Good morning!

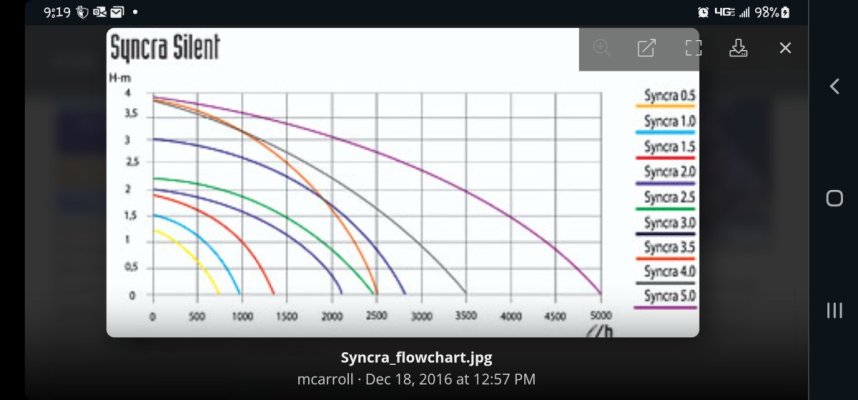

I currently have a 55 Gal tank and can not drill in the side of the tank so thinking about a HOB overflow. The overflow I’m looking at says it has 600 gph flow rate. When looking for a return pump I’m assuming I need something with around that same flow rate if not the same. Attached are some pictures of what I’m thinking please let me know your thoughts or anything else I should be doing regarding this!!! I am going to use a 20 gal long for the sump. I attached 2 pictures of pumps one that has a flow rate of a little under 600 and one a little over

I currently have a 55 Gal tank and can not drill in the side of the tank so thinking about a HOB overflow. The overflow I’m looking at says it has 600 gph flow rate. When looking for a return pump I’m assuming I need something with around that same flow rate if not the same. Attached are some pictures of what I’m thinking please let me know your thoughts or anything else I should be doing regarding this!!! I am going to use a 20 gal long for the sump. I attached 2 pictures of pumps one that has a flow rate of a little under 600 and one a little over