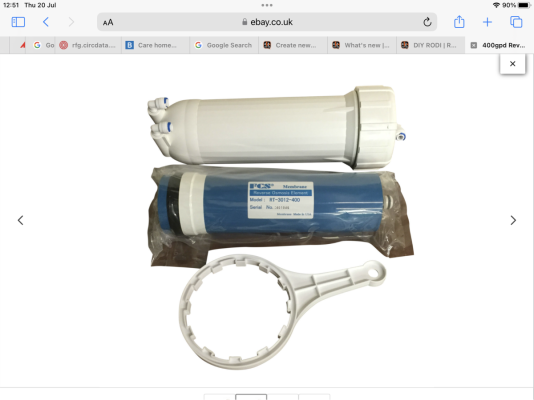

I have just got my DIY RODI setup into basic working configuration. It will be developed further, the solenoid valves will be used to allow control of startup using an automated PIC micro based system that will also monitor conductivity at 4 sample sites. At the moment it’s all manually controlled and I have been looking at real world flow rates through the system by timing collection in a measure. For some reason it seemed like a good idea at the time to use a 400gpd membrane and optimise the system around that. Might have been overkill . My current understanding is that the higher flow membranes give a worse rejection ratio, I don’t yet have conductivity measurements to assess this. Raw water is pretty hard in this area with reasonably good mains pressure. Just wondered what the experts here think about using the setup for now in its basic configuration, underutilising the RO membrane. I fitted an adjustable regulator to allow waste water flow to be tuned. Obviously if you turn that flow up inlet pressure does drop a little. Max inlet pressure with inadequate waste flow was about 43psi, at the low end of acceptable. Tuning the waste flow allowed me to set up a 4:1 waste product ratio, real world product flow is about 120 UK gpd and inlet pressure is now 40 psi which I appreciate is lower end. Product water quality appears good based on kit water quality testing, no TDS as yet. My question is whether the system as configured will burn though DI resin. I think whatever I may need to add a much larger resin stage than the current two 10 inch housings. No problem to do this really. The inlet pressure can be increased by adding a booster pump, maybe such membranes really require one of those? Interested in peoples thoughts on this, TIA

Steve

Steve