- Joined

- Jun 26, 2020

- Messages

- 435

- Reaction score

- 335

Hello guys

I have been working on my 120gallon/40breeder sump forquite some time now.

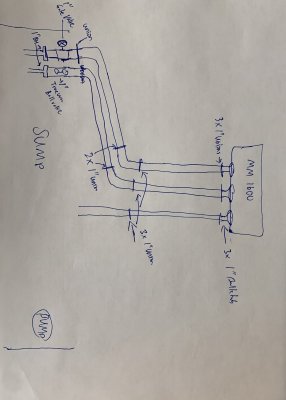

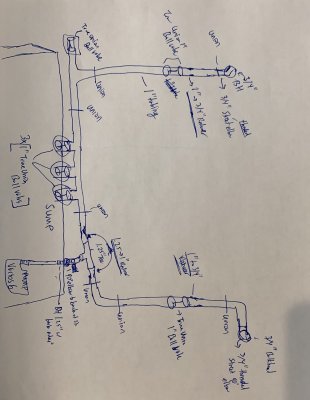

finally time to PLUMB and I have a couple questions. Below are pictures of what I drew. I have been thinking about this for 2 days and I think I have FINALLY decided on the design but would love any ideas/tweaks you experts would recommend.

The drain lines are pretty simple in my thinking. I have the gate valve as low as possible which is recommend a lot and I added a ball valve to the 2nd drain just for symmetry and instead of a union. (I know it’s a bit more pricey).

My real help is needed with my returns.

1. I had bought all 3/4 tubing for the return (due to my bulkheads) then realized the varios6 has a 1.25in barb output. So I decided to buy more of the 1” red tubing for the drain and use it for the return as well. I couldn’t find a sch 80 1.25 to 1” reducing tee so I had to put couplers on both sides of the 1.25” tee. Is this look good so far?

2. The way my stand is (I bought system used but never again) the first return can only go back with that 90 turn before the bulkhead. Which I think is ok since this is the route of least resistance anyways. Plus I need a ball valve to restrict flow a little too. Now...Where should I put this ball valve? I put it higher up behind the stand and use this as the spot to reduce to the 3/4 tubing. Or should I put it right off the tee in the sump area? My concern would be flow and noise level(if this matters). Then I would just reduce the 1” to 3/4” at the top before the bulkhead I guess.

3. Just want overall feedback on manifold design and issues and more or less union placement etc...

Thank you all... @revhtree I love this site

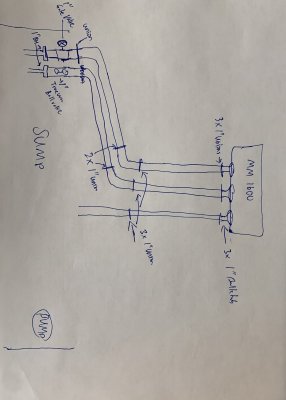

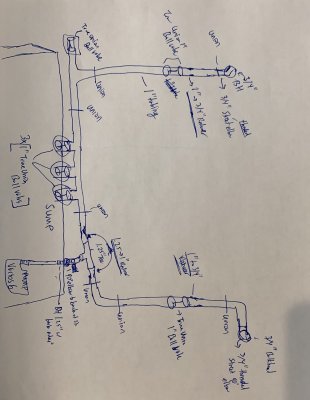

I have been working on my 120gallon/40breeder sump forquite some time now.

finally time to PLUMB and I have a couple questions. Below are pictures of what I drew. I have been thinking about this for 2 days and I think I have FINALLY decided on the design but would love any ideas/tweaks you experts would recommend.

The drain lines are pretty simple in my thinking. I have the gate valve as low as possible which is recommend a lot and I added a ball valve to the 2nd drain just for symmetry and instead of a union. (I know it’s a bit more pricey).

My real help is needed with my returns.

1. I had bought all 3/4 tubing for the return (due to my bulkheads) then realized the varios6 has a 1.25in barb output. So I decided to buy more of the 1” red tubing for the drain and use it for the return as well. I couldn’t find a sch 80 1.25 to 1” reducing tee so I had to put couplers on both sides of the 1.25” tee. Is this look good so far?

2. The way my stand is (I bought system used but never again) the first return can only go back with that 90 turn before the bulkhead. Which I think is ok since this is the route of least resistance anyways. Plus I need a ball valve to restrict flow a little too. Now...Where should I put this ball valve? I put it higher up behind the stand and use this as the spot to reduce to the 3/4 tubing. Or should I put it right off the tee in the sump area? My concern would be flow and noise level(if this matters). Then I would just reduce the 1” to 3/4” at the top before the bulkhead I guess.

3. Just want overall feedback on manifold design and issues and more or less union placement etc...

Thank you all... @revhtree I love this site