Hi All,

I'm in the process of overcomplicating my RODI and Saltwater Mixing Station. For context, the gear and automation is a large part of the appeal of reefing for me, so I'm interested in learning how things work, and creating a system that is convenient, cool, and eventually automated!.

I don't care too much how overkill/unnecessary it may be, since, again, this is my idea of fun. I know its a bit of blasphemy to go this far without actually knowing the TDS of my feed water. I know that there's a chance I'd be perfectly fine with next to nothing for RODI, but minimizing my own work is very much not the point of practically anything I do. Its much more fun to learn and build, even if it's not necessary (or advisable ).

).

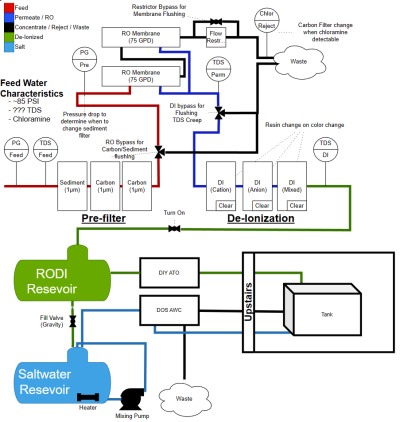

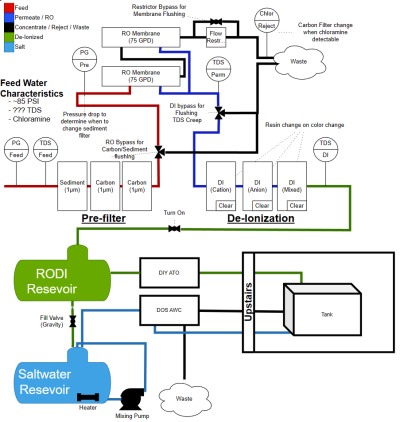

I've come up with the following design, but I wanted to see if any more experienced folks had some thoughts/suggestions on operating/maintaining it efficiently, or could help me with anwers to a few points I'm probably not grasping right. I eventually want to automate the production of RODI water implement auto-flushing and TDS monitoring myself, but for starters I'm thinking manual RODI making is gonna be A-OK.

As to where I am in the design/execution at the moment: I have everything listed below except for the flow restrictor, the DIY ATO, and misc. connectors/valves, and the saltwater mixing pump/heater. The scope of what I'm concerned with at the moment is on the RODI side, not so much the saltwater stuff.

(Woops, I realize I left off the auto-shut-off!)

Questions I have are (See if you can sense the theme):

1. In all the examples I've seen, the flow restrictor on the concentrate lines is a fixed cc/min. Is using a needle/precision valve (like this one) a good/bad idea? Are they reliable or do they wiggle their way out of their settings over time, break easily, etc...? My thought process here is that one piece that I can set to the optimal setting and forget is probably better than buying the wrong one and finding I want a different value, or having to buy a new when I tinker with the system in the future.

2. More about the mechanics... With no flow restrictor in place, is the Feed-to-Concentrate path in an RO membrane more or less unrestricted flow with trivial pressure drop? I have that picture in my head, leading to this "Concentrate staging" approach looking just like a way to scale up the production (and the waste) proportionally, but I'm not sure that's correct (I mean, its sold as "water saving", but what's the math behind that?) What's the meaningful difference between putting a T on the feed and running both RO membranes in "parallel" that way vs feeding the concentrate of one to the feed of the other, would there be a difference in pressure across each membrane?

3. More generally... Seems like there should be a way to say. "Here's my feed pressure, temperature, incoming TDS, and membrane characteristics/configuration. To target X TDS, I'd need Y Flow restriction and have Z waste to product ratio." Where's the magic formula (or the bits and pieces required to get there)?

Thanks for reading! (and thanks in advance for any input you may have!!)

(Edit: Fixed image upload)

I'm in the process of overcomplicating my RODI and Saltwater Mixing Station. For context, the gear and automation is a large part of the appeal of reefing for me, so I'm interested in learning how things work, and creating a system that is convenient, cool, and eventually automated!.

I don't care too much how overkill/unnecessary it may be, since, again, this is my idea of fun. I know its a bit of blasphemy to go this far without actually knowing the TDS of my feed water. I know that there's a chance I'd be perfectly fine with next to nothing for RODI, but minimizing my own work is very much not the point of practically anything I do. Its much more fun to learn and build, even if it's not necessary (or advisable

I've come up with the following design, but I wanted to see if any more experienced folks had some thoughts/suggestions on operating/maintaining it efficiently, or could help me with anwers to a few points I'm probably not grasping right. I eventually want to automate the production of RODI water implement auto-flushing and TDS monitoring myself, but for starters I'm thinking manual RODI making is gonna be A-OK.

As to where I am in the design/execution at the moment: I have everything listed below except for the flow restrictor, the DIY ATO, and misc. connectors/valves, and the saltwater mixing pump/heater. The scope of what I'm concerned with at the moment is on the RODI side, not so much the saltwater stuff.

(Woops, I realize I left off the auto-shut-off!)

Questions I have are (See if you can sense the theme):

1. In all the examples I've seen, the flow restrictor on the concentrate lines is a fixed cc/min. Is using a needle/precision valve (like this one) a good/bad idea? Are they reliable or do they wiggle their way out of their settings over time, break easily, etc...? My thought process here is that one piece that I can set to the optimal setting and forget is probably better than buying the wrong one and finding I want a different value, or having to buy a new when I tinker with the system in the future.

2. More about the mechanics... With no flow restrictor in place, is the Feed-to-Concentrate path in an RO membrane more or less unrestricted flow with trivial pressure drop? I have that picture in my head, leading to this "Concentrate staging" approach looking just like a way to scale up the production (and the waste) proportionally, but I'm not sure that's correct (I mean, its sold as "water saving", but what's the math behind that?) What's the meaningful difference between putting a T on the feed and running both RO membranes in "parallel" that way vs feeding the concentrate of one to the feed of the other, would there be a difference in pressure across each membrane?

3. More generally... Seems like there should be a way to say. "Here's my feed pressure, temperature, incoming TDS, and membrane characteristics/configuration. To target X TDS, I'd need Y Flow restriction and have Z waste to product ratio." Where's the magic formula (or the bits and pieces required to get there)?

Thanks for reading! (and thanks in advance for any input you may have!!)

(Edit: Fixed image upload)