Greetings,

Where do I start...

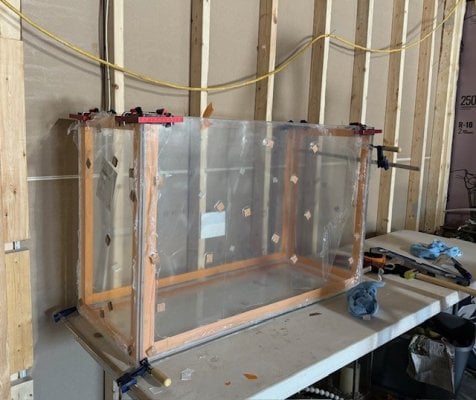

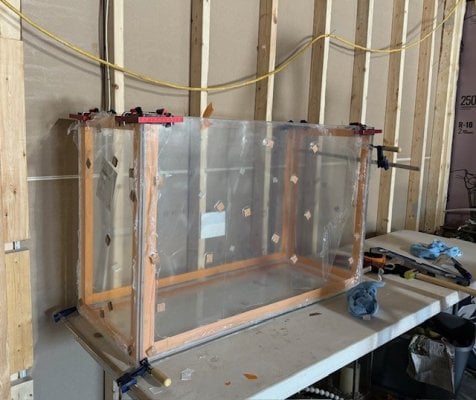

I built this approx 100 gallon tank a few moths ago. The glass is low-e, 10MM and 44"w x 18" deep x 28" h. Silcon used was ASI clear and set up for 2 weeks or so. I did a leek test in the basement for a week and then set up in family room upstairs.

The tank was going well with no leaks and disaster knocked at the door one Sunday evening. Long story short, the tank lost seal in the back center bottom and back panel. 100 gallons gushed out everywhere.

I am in the process of tearing the tank apart and so far, have removed the bottom. The bottom side where the leak occurred seemed to be easier to separate compared to other areas. I started on the sides, and they seem to be very tight. I will take all panels apart and completely clean the old silicone and residue off, I know the drill.

I clamped all sides and probably had a good seal on these panels. I did not clamp the bottom and I'm thinking this was likely the mistake.

I'm debating to re-do myself or take the panels to the glass shop and have them do it.

If I do it, I will get more clamps and clamp everything.

Questions:

-When clamping how much space should be left between the panels? Enough pressure to remove bubbles?

-What are thoughts on bracing?

-Open to reasonable tips and suggestions.

Thanks!

Where do I start...

I built this approx 100 gallon tank a few moths ago. The glass is low-e, 10MM and 44"w x 18" deep x 28" h. Silcon used was ASI clear and set up for 2 weeks or so. I did a leek test in the basement for a week and then set up in family room upstairs.

The tank was going well with no leaks and disaster knocked at the door one Sunday evening. Long story short, the tank lost seal in the back center bottom and back panel. 100 gallons gushed out everywhere.

I am in the process of tearing the tank apart and so far, have removed the bottom. The bottom side where the leak occurred seemed to be easier to separate compared to other areas. I started on the sides, and they seem to be very tight. I will take all panels apart and completely clean the old silicone and residue off, I know the drill.

I clamped all sides and probably had a good seal on these panels. I did not clamp the bottom and I'm thinking this was likely the mistake.

I'm debating to re-do myself or take the panels to the glass shop and have them do it.

If I do it, I will get more clamps and clamp everything.

Questions:

-When clamping how much space should be left between the panels? Enough pressure to remove bubbles?

-What are thoughts on bracing?

-Open to reasonable tips and suggestions.

Thanks!