I received several inquiries, so I decided to put something together. It may not be orderly or proper but if your interested here it is.

Recipe for 80/20 Light supports, Aquatic life Hybrid Fixture

80/20 Inc 15 Series 1.5” x 1.5" Aluminum Extrusion Part #1515-BLACK x 24" Long N @2pc

80/20 Inc 15 Series 1.5” x 1.5" Aluminum Extrusion Part #1515-BLACK x 72" Long N (60" may work for most) @2pc

80/20 Inc T-Slot Aluminum 4 Hole Tall Gusseted Bracket 15 Series #4336-BLACK N @2pc

80/20 Inc 15 Series Black Standard T-Slot Cover x 72.5" Long Part #2110 N helps to contain wiring in channels and gives a clean look

80/20 Inc 15 and 40 Series Steel Milling Connector Part #14132 N vertical to horizontal connection (back side) @2

#3314 5/16-18 x .750" Button Head Socket Cap Screw (B...

#3117 5/16-18 x .875" Button Head Socket Cap Screw For use w/ lock washer recommended

#3203 15 Series 5/16-18 Standard Slide-In T-Nut @25 pc

80/20 Inc 15 Series Black Star Handle Linear Bearing Brake Kit Part #6802 N Recommend all four bearings but two will suffice (one per side) or see below

8020 to Hybrid

80/20 Inc T-Slot Aluminum 2 Hole Inside Corner Bracket 15 Series 4302-BLACK N @ 4 or 8 for heavy load. This is a standard L-bracket with two 5/16" holes.

A better option IF using the Extended M5's (I believe?) That Aquatic Life has generously provided to me for this project.

The 4509-Black 10 to 15 Series 2 Hole - Lite Transition Inside Corner Bracket, it has 1 @ 5/16" hole & 1 @ 1/4" hole.

I could not use the M5's due to the larger 5/16" hole. I had to stack washers thus eating up scarce threads. I think some #8 or #10 fender washers along with a nylock nut would suffice with the 1/4" hole that the 4509 provides when using the extended AL T-slot studs.

80/20 Inc 15 Series ABS Plastic End Cap w/Fastener for 1515 #2030-PLAIN N @2pc

8020 to Stand

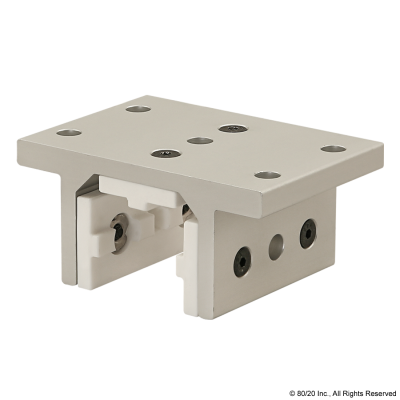

15 Series 3 Slot Mount - Double Flange Short High-Cycle Linear Bearing with Brake Holes silver #6535 $67.20 each @ 4pc.

1/4" angle can substitute at a significant savings but you will need to machine your holes accurately

An option is to purchase an 80/20 angle bracket #4512 BUT this would place vertical rail flush with the back of stand/tank! So a shim will need to be used between stand and mounting angle

(at least 3/8" shim/spacer)

#4281 below might be used. The slotted end could be fastened to stand and use outside series of holes to attach to vertical supports, this would stand-off rails 1.5" away from tank. I would use 2 per connection and a total of 8 pc's for this project with extra fasteners/t-nuts.

#4512 #4281 #6535

https://8020.net/ Is an excellent resource, check it out! The eBay store has pre-cut extrusions and will save you on shipping by ordering the shortest length possible

8020 Catalog PDF download (basics) https://www.bondfluidaire.com/wp-content/uploads/2017/12/8020-tslot.pdf

TIPS & TRICKS

You can use a miter saw with carbide tooth blade to cut extruded aluminum, just cut SLOW and steady. It will make a mess with chips, keep that in mind for the little bare feet that may come in contact with the shavings or from tracking them into the house.

Horizontal to vertical connection, tighten the backside connection first Part #14132 before tightening gusset #4336 this will kick the front slightly upward and will level out when the lights are installed.

Bracket mounting to stand mount your brackets to the 24" section of extrusion, this will align your bearings/brackets and create a template for your holes & vertical rails. I drilled one hole and fastened the entire unit to the stand then placed a level on the 24" section, and then repeated the process alternating from top to bottom. The bearings are so smooth that I recommend installing 4 break kits or use a fastener w/t-nut to lock rails down after setting fixture height.

Counter sink and use Flathead machine screws in cabinet if sump will be in proximity to the fasteners. Red Sea and similar sumps are glass and don't provide much room.

Buy extra fasteners, count up and add 25%. You may wont to mount something to the rails like ballasts behind the cabinet.

Brake Kit Part #6802 is what I chose and is $2.00 each but a better option would be #6807 Brake $13.75 increased torq requiring 1 per rail. Several colors to choose from.

The better brake has a spring-loaded engage disengage, something like a ratchet. It will also save the skin on your knuckles...Ouch!

Mounting the Fixture to 8020 is a whole other story. I touched on it above and this was my solution but required time on the lathe and fitting each by grinding down to exact tolerances.

Good luck Mounting your light

Recipe for 80/20 Light supports, Aquatic life Hybrid Fixture

80/20 Inc 15 Series 1.5” x 1.5" Aluminum Extrusion Part #1515-BLACK x 24" Long N @2pc

80/20 Inc 15 Series 1.5” x 1.5" Aluminum Extrusion Part #1515-BLACK x 72" Long N (60" may work for most) @2pc

80/20 Inc T-Slot Aluminum 4 Hole Tall Gusseted Bracket 15 Series #4336-BLACK N @2pc

80/20 Inc 15 Series Black Standard T-Slot Cover x 72.5" Long Part #2110 N helps to contain wiring in channels and gives a clean look

80/20 Inc 15 and 40 Series Steel Milling Connector Part #14132 N vertical to horizontal connection (back side) @2

#3314 5/16-18 x .750" Button Head Socket Cap Screw (B...

#3117 5/16-18 x .875" Button Head Socket Cap Screw For use w/ lock washer recommended

#3203 15 Series 5/16-18 Standard Slide-In T-Nut @25 pc

80/20 Inc 15 Series Black Star Handle Linear Bearing Brake Kit Part #6802 N Recommend all four bearings but two will suffice (one per side) or see below

8020 to Hybrid

80/20 Inc T-Slot Aluminum 2 Hole Inside Corner Bracket 15 Series 4302-BLACK N @ 4 or 8 for heavy load. This is a standard L-bracket with two 5/16" holes.

A better option IF using the Extended M5's (I believe?) That Aquatic Life has generously provided to me for this project.

The 4509-Black 10 to 15 Series 2 Hole - Lite Transition Inside Corner Bracket, it has 1 @ 5/16" hole & 1 @ 1/4" hole.

I could not use the M5's due to the larger 5/16" hole. I had to stack washers thus eating up scarce threads. I think some #8 or #10 fender washers along with a nylock nut would suffice with the 1/4" hole that the 4509 provides when using the extended AL T-slot studs.

80/20 Inc 15 Series ABS Plastic End Cap w/Fastener for 1515 #2030-PLAIN N @2pc

8020 to Stand

15 Series 3 Slot Mount - Double Flange Short High-Cycle Linear Bearing with Brake Holes silver #6535 $67.20 each @ 4pc.

1/4" angle can substitute at a significant savings but you will need to machine your holes accurately

An option is to purchase an 80/20 angle bracket #4512 BUT this would place vertical rail flush with the back of stand/tank! So a shim will need to be used between stand and mounting angle

(at least 3/8" shim/spacer)

#4281 below might be used. The slotted end could be fastened to stand and use outside series of holes to attach to vertical supports, this would stand-off rails 1.5" away from tank. I would use 2 per connection and a total of 8 pc's for this project with extra fasteners/t-nuts.

#4512 #4281 #6535

https://8020.net/ Is an excellent resource, check it out! The eBay store has pre-cut extrusions and will save you on shipping by ordering the shortest length possible

8020 Catalog PDF download (basics) https://www.bondfluidaire.com/wp-content/uploads/2017/12/8020-tslot.pdf

TIPS & TRICKS

You can use a miter saw with carbide tooth blade to cut extruded aluminum, just cut SLOW and steady. It will make a mess with chips, keep that in mind for the little bare feet that may come in contact with the shavings or from tracking them into the house.

Horizontal to vertical connection, tighten the backside connection first Part #14132 before tightening gusset #4336 this will kick the front slightly upward and will level out when the lights are installed.

Bracket mounting to stand mount your brackets to the 24" section of extrusion, this will align your bearings/brackets and create a template for your holes & vertical rails. I drilled one hole and fastened the entire unit to the stand then placed a level on the 24" section, and then repeated the process alternating from top to bottom. The bearings are so smooth that I recommend installing 4 break kits or use a fastener w/t-nut to lock rails down after setting fixture height.

Counter sink and use Flathead machine screws in cabinet if sump will be in proximity to the fasteners. Red Sea and similar sumps are glass and don't provide much room.

Buy extra fasteners, count up and add 25%. You may wont to mount something to the rails like ballasts behind the cabinet.

Brake Kit Part #6802 is what I chose and is $2.00 each but a better option would be #6807 Brake $13.75 increased torq requiring 1 per rail. Several colors to choose from.

The better brake has a spring-loaded engage disengage, something like a ratchet. It will also save the skin on your knuckles...Ouch!

Mounting the Fixture to 8020 is a whole other story. I touched on it above and this was my solution but required time on the lathe and fitting each by grinding down to exact tolerances.

Good luck Mounting your light