- Joined

- May 27, 2020

- Messages

- 27

- Reaction score

- 34

Hi Guys

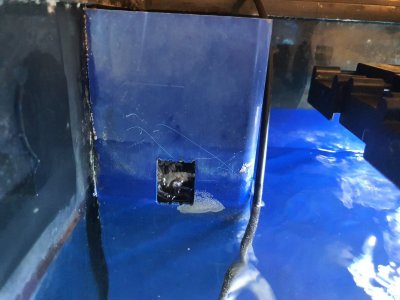

The water level in my display tank is just under the top acrylic, so I can see a half inch above my water, which isnt great.

My sump is also fairly noisy from the drain pipe into it, as the display water level is so low it takes quite a bit of air with it and I get a lot of gargling.

I have seen most people say to never restrict the flow onto the sump by turning the valve, but I tried it anyway to see what would happen, and voila my display level started to rise and the noise issue disappeared, however it went too high and I couldn't seem to find the sweet spot.

Any ideas on what I could do with this, or is it a case of sitting and watching my levels until they level themselves off where I want them, by restricting flow into the sump?

Many Thanks!

The water level in my display tank is just under the top acrylic, so I can see a half inch above my water, which isnt great.

My sump is also fairly noisy from the drain pipe into it, as the display water level is so low it takes quite a bit of air with it and I get a lot of gargling.

I have seen most people say to never restrict the flow onto the sump by turning the valve, but I tried it anyway to see what would happen, and voila my display level started to rise and the noise issue disappeared, however it went too high and I couldn't seem to find the sweet spot.

Any ideas on what I could do with this, or is it a case of sitting and watching my levels until they level themselves off where I want them, by restricting flow into the sump?

Many Thanks!