Hello R2R Community.

This will be my first post, I am usually a spectator, but since I could not find anything in the whole web related to this problem, I wanted to share this information with the community.

I have two Vectra pumps, M2 and L2. Two weeks ago, I heard water noises coming from my tank. The Vectra M2 was off, and its Quiet Drive was Flashing Red/Orange, I was able to connect via Mobius and there it was, "Thermistor Error".

Looking into the forums, meaning this community, I found that there are many other users that faced this very same problem.

The problem, according to Ecotech webpage is that a component inside the motor has gone bad, the solution they propose is to ship back the pump to them so they can either, fix it or send you another pump, of course if you are out of warranty, you would be charged for it.

I had only used this pump for no more than two months, the problem is that I bought it from a fellow reefer locally, he bought the pump brand new in California and it was too big for his tank (in Mexico), the pump was stored in his house for a bit more than a year, then I bought it from him. He is a close friend, so I know that is true.

We both live in Guadalajara, Mexico, so shipping the pump back is not an option for us. Only the shipping charges would be enough to buy another pump.

Long story short, out of warranty with a shiny almost new pump.

I tried everything, disassembly/clean the motor, clean the connectors, nothing helped. So, I was about to buy another pump, and decided to mess with the electronics of the Vectra M2. I am an electronics engineer, and the pump was already dead, I had nothing to lose.

My findings were really helpful for me.

There was nothing in the web regarding the guts of the Vectra, nothing, not a single connection pinout, circuit, tear down video, NOTHING. So, I went totally blind during the disassembly.

I started by taking measurements for the Vectra L2 that was working perfectly. Starting by the male connector coming from the motor, we have five connections, three are the BLDC motor (Brushless DC), and the other two are for the so called Thermistor, this is a device that constantly monitors the temperature inside the Vectra, this type of devices changes its electrical resistance (ohms) when they are exposed to thermal changes, this is how the Quiet Drive knows if the pump goes dry (it increases its temperature, drastically).

This is an easy fix if you are familiar with electronics, if you are not, and you have a dead Vectra with the same error, take it to any electronics repair shop and show them this thread, they will understand it.

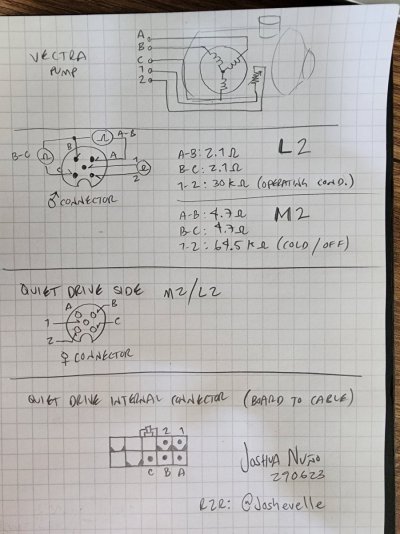

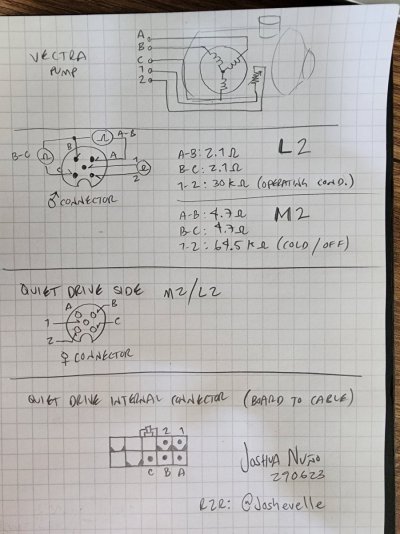

This is the internal diagram of the Vectra, as well as the connection to the Quiet Drive:

From the pump side, we have the male connector. BLDC Motor are terminals A, B and C, Thermistor terminals are 1 and 2. While the Vectra L2 was working, I shut it off, and took the measurement for the Thermistor resistance, it was 30K ohms. The Vectra M2, was off for more than a week, the "cold" or off status measurement for the Thermistor was 64.5 ohms, which must be its value at 25C (water temperature), yes it was inside the sump the whole time.

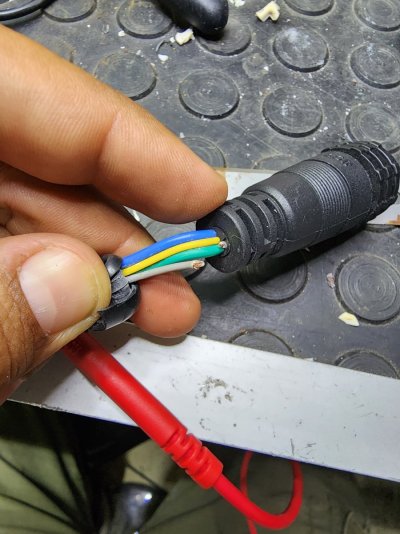

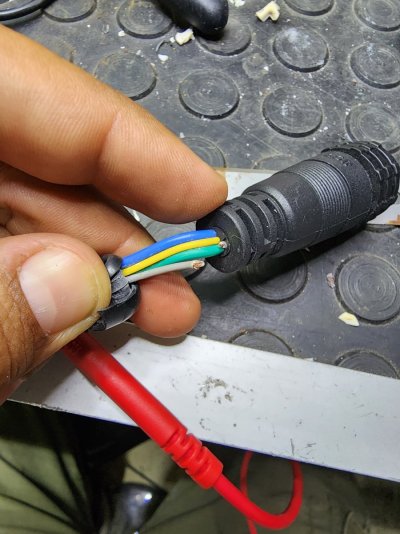

This is the male connector from the pump:

This is the female connector from the Quiet Drive side (sorry for the blurry image):

I was tracking the problem by taking the measurements with all the Vectra M2 connections done, and the Quiet Drive PCB exposed. The problem was not in the motor, it was in the tiny cable going from the female connector in the Quiet Drive, to the PCB inside the Quiet Drive.

First you have to measure directly in the male connector going into the PCB board in the Quiet Drive, is the connector highlighted in green, sorry I did not take a picture while disconnected, but you have to press the upper tab and pull the connector:

I tracked it down by measuring continuity and there was an error in the connection #1, that corresponds to the Thermistor, the Quiet Drive was sensing an "open" circuitry in the Thermistor, hence the error message was Thermistor Error. I fixed this by adding a "bridge", which is a small cable added to the gray cable.

Notice how the gray cable is already cut down, but it was not like that when I removed the black insulation material, the gray cable was in mint conditions, except it did not have electrical continuity. You would need a bit of experience to know where is the open circuit, but is not that hard, I use a multimeter and a small needle to pinch the cable.

After this fix, the pump has been running perfectly, no errors whatsoever.

The cause? well, I noticed that the two cables for the Thermistor are a smaller than the three cables for the BLDC motor (you can notice that in the picture). Mixing cable wires with different gauges inside the same cable is not a good idea, from the manufacturer's perspective, you could save a couple of cents per meter of cable, of course, cents adds up when you are buying kilometers of cable.... From the user point of view, you are paying a bunch of money for a top-quality product that, apparently, is failing in the field.

The natural bends in the external cable during the installation, stress up the inside wires, the two cables corresponding to the Thermistor are the most prompt to break because of the stress.

Summary: if you have a Vectra pump with a Thermistor Error and you are out of warranty, start by measuring continuity using a multi meter, disassembly the Quiet Drive and make sure that the PCB has the corresponding measurements for the BLDC motor (A, B and C connections, shown in my notes) and the Thermistor (1 and 2). If it doesn't, track the open circuitry, chances are, you can fix your own pump.

sorry for the long thread, but I wanted to give as much information as possible, I couldn't find anything in the web, and I hope I can help a fellow reefer by posting this.

Saludos from Guadalajara Jalisco, Mexico.

Joshua Nuno _\m/

This will be my first post, I am usually a spectator, but since I could not find anything in the whole web related to this problem, I wanted to share this information with the community.

I have two Vectra pumps, M2 and L2. Two weeks ago, I heard water noises coming from my tank. The Vectra M2 was off, and its Quiet Drive was Flashing Red/Orange, I was able to connect via Mobius and there it was, "Thermistor Error".

Looking into the forums, meaning this community, I found that there are many other users that faced this very same problem.

The problem, according to Ecotech webpage is that a component inside the motor has gone bad, the solution they propose is to ship back the pump to them so they can either, fix it or send you another pump, of course if you are out of warranty, you would be charged for it.

I had only used this pump for no more than two months, the problem is that I bought it from a fellow reefer locally, he bought the pump brand new in California and it was too big for his tank (in Mexico), the pump was stored in his house for a bit more than a year, then I bought it from him. He is a close friend, so I know that is true.

We both live in Guadalajara, Mexico, so shipping the pump back is not an option for us. Only the shipping charges would be enough to buy another pump.

Long story short, out of warranty with a shiny almost new pump.

I tried everything, disassembly/clean the motor, clean the connectors, nothing helped. So, I was about to buy another pump, and decided to mess with the electronics of the Vectra M2. I am an electronics engineer, and the pump was already dead, I had nothing to lose.

My findings were really helpful for me.

There was nothing in the web regarding the guts of the Vectra, nothing, not a single connection pinout, circuit, tear down video, NOTHING. So, I went totally blind during the disassembly.

I started by taking measurements for the Vectra L2 that was working perfectly. Starting by the male connector coming from the motor, we have five connections, three are the BLDC motor (Brushless DC), and the other two are for the so called Thermistor, this is a device that constantly monitors the temperature inside the Vectra, this type of devices changes its electrical resistance (ohms) when they are exposed to thermal changes, this is how the Quiet Drive knows if the pump goes dry (it increases its temperature, drastically).

This is an easy fix if you are familiar with electronics, if you are not, and you have a dead Vectra with the same error, take it to any electronics repair shop and show them this thread, they will understand it.

This is the internal diagram of the Vectra, as well as the connection to the Quiet Drive:

From the pump side, we have the male connector. BLDC Motor are terminals A, B and C, Thermistor terminals are 1 and 2. While the Vectra L2 was working, I shut it off, and took the measurement for the Thermistor resistance, it was 30K ohms. The Vectra M2, was off for more than a week, the "cold" or off status measurement for the Thermistor was 64.5 ohms, which must be its value at 25C (water temperature), yes it was inside the sump the whole time.

This is the male connector from the pump:

This is the female connector from the Quiet Drive side (sorry for the blurry image):

I was tracking the problem by taking the measurements with all the Vectra M2 connections done, and the Quiet Drive PCB exposed. The problem was not in the motor, it was in the tiny cable going from the female connector in the Quiet Drive, to the PCB inside the Quiet Drive.

First you have to measure directly in the male connector going into the PCB board in the Quiet Drive, is the connector highlighted in green, sorry I did not take a picture while disconnected, but you have to press the upper tab and pull the connector:

I tracked it down by measuring continuity and there was an error in the connection #1, that corresponds to the Thermistor, the Quiet Drive was sensing an "open" circuitry in the Thermistor, hence the error message was Thermistor Error. I fixed this by adding a "bridge", which is a small cable added to the gray cable.

Notice how the gray cable is already cut down, but it was not like that when I removed the black insulation material, the gray cable was in mint conditions, except it did not have electrical continuity. You would need a bit of experience to know where is the open circuit, but is not that hard, I use a multimeter and a small needle to pinch the cable.

After this fix, the pump has been running perfectly, no errors whatsoever.

The cause? well, I noticed that the two cables for the Thermistor are a smaller than the three cables for the BLDC motor (you can notice that in the picture). Mixing cable wires with different gauges inside the same cable is not a good idea, from the manufacturer's perspective, you could save a couple of cents per meter of cable, of course, cents adds up when you are buying kilometers of cable.... From the user point of view, you are paying a bunch of money for a top-quality product that, apparently, is failing in the field.

The natural bends in the external cable during the installation, stress up the inside wires, the two cables corresponding to the Thermistor are the most prompt to break because of the stress.

Summary: if you have a Vectra pump with a Thermistor Error and you are out of warranty, start by measuring continuity using a multi meter, disassembly the Quiet Drive and make sure that the PCB has the corresponding measurements for the BLDC motor (A, B and C connections, shown in my notes) and the Thermistor (1 and 2). If it doesn't, track the open circuitry, chances are, you can fix your own pump.

sorry for the long thread, but I wanted to give as much information as possible, I couldn't find anything in the web, and I hope I can help a fellow reefer by posting this.

Saludos from Guadalajara Jalisco, Mexico.

Joshua Nuno _\m/