- Joined

- Dec 5, 2017

- Messages

- 2,888

- Reaction score

- 4,377

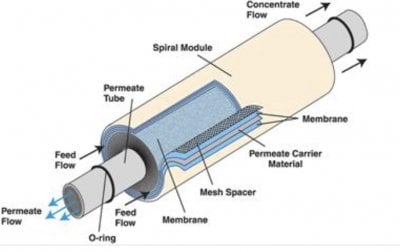

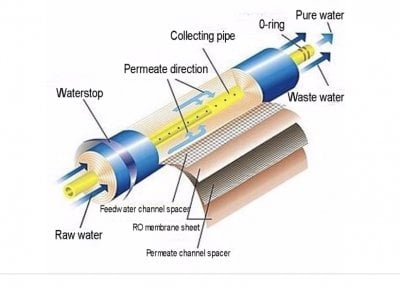

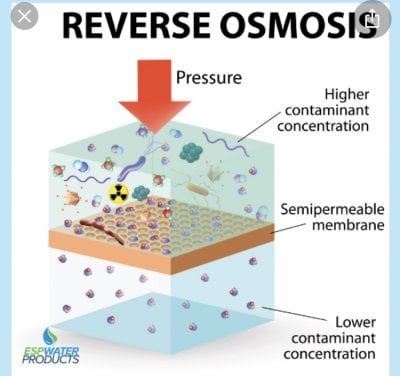

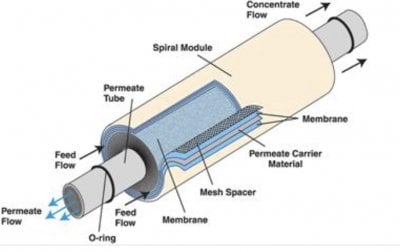

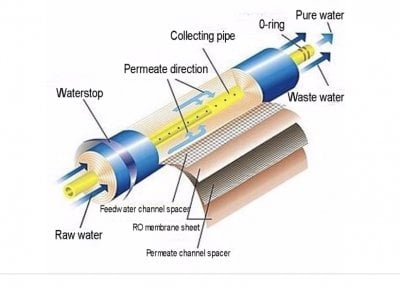

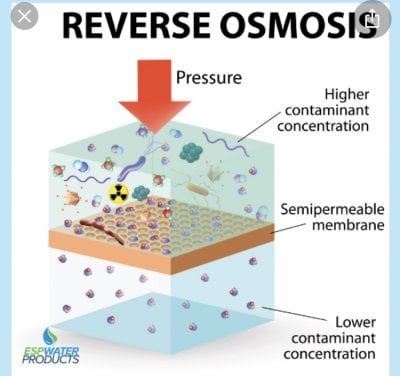

An RO membrane forces molecules through a semipermeable membrane (certain substances can pass through but not others) to form a less concentrated solution then you started with. The inside of the membrane looks like so:

Some of the things an RO membrane can filter out are:

Lead

Copper

Arsenic

Nitrates and Nitrites

Chromium

Selenium

Fluoride

Radium

Barium

Cadmium

TDS

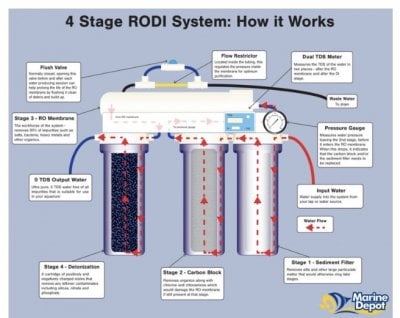

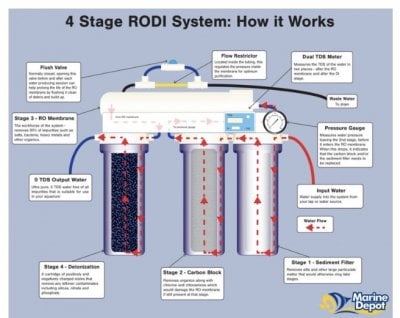

The filters on an RO/DI filter are called stages. The first few stages consist of prefilters that help protect the RO membrane. The first prefilter is a sediment filter. It helps remove large sediment. The next stage is a carbon filter which takes out chlorine. Some filters run two sediment and or two carbon filters. You start with a course filter and then go to a tighter one. From there we go into the RO membrane. The last stage is running the water though a DI filter this takes out the last bit of contaminates that the RO can’t get. The DI filter will take out anything with an ionic charge. You can run two DI filters to get the maximum amount of life out of your DI resin. This is a digram of an RO/DI filter.

An important thing to note about RO filters is that the membrane is flushed with water the whole time you are running the filter. The water that’s used to flush the membrane is waste water. The amount of waste water your filter will produce is giving in a ratio so for example a filter might say it has a 3:1 waste water ratio. For every one gallon of good water you make you will make 3 of waste water. Let’s say we want to make 5 gallons of water for our tank that means we will end up with 15 gallons of waster water and we will end up running 20 gallons of water through the filter. There are a few things we can do to lower the amount of waste water the filter will produce. We can run two RO membranes. We could also run a booster pump to feed the filter.

There are a few things we can do to get the maximum amount of life out of our filters. We can test the water for Cl after the last carbon filter to tell us when to change the carbon out. We can also put a pressure gauge before the RO membrane when we see the pressure drop this lets us know the prefilters are starting to plug and we should change them. We can also add a flush kit to the RO membrane. This allows water to bypass the flow restrictor and flush the membrane clean. The membrane should be flushed before and after each use. You can buy an automatic flush kit which will flush the membrane for you. This will help extend the life of the RO which is the most expensive to replace. The flow restrictors job is to keep the membrane under pressure. The last thing we can do is use a TDS meter. There are two types inline and hand held. If we test the TDS after the DI resin anything higher then 0 tells you it’s time to change the resin. We can find out how well our membrane is preforming by testing the TDS of our tap water and the TDS after the RO membrane. Let’s say we have tap water that’s 200 TDS and after the RO we get 4 TDS our rejection rate is:

4/200=0.02

100(0.02)=2

100-2=98%

Once the rejection rate starts dropping by 3 or 4 % it’s time to start thinking of replacing the membrane. The membrane should tell you the expected rejection rate you will get.

There are a few things that can cause an RO/DI filter not to work well. One is if your on well water and your water has CO2 in it. If that’s the case then we need to degass the water before we run it though the DI filter. This can be done by collecting the water after the RO and putting and air stone in it. Let it sit for a day then use a small pump to run it through the DI resin or something like this can be made to degass the water as your running.

www.reef2reef.com

www.reef2reef.com

Another potential problem is if your water is treated with Chloramines. If that’s the case then you need to run an additional prefilter.

www.bulkreefsupply.com

www.bulkreefsupply.com

An RO/DI filter looks like this. You can see the 2nd RO on top of the main one and you can see the flow restrictor in the 2nd picture.

An automatic RO/DI flush kit looks like this.

And a booster pump looks like this:

Some of the things an RO membrane can filter out are:

Lead

Copper

Arsenic

Nitrates and Nitrites

Chromium

Selenium

Fluoride

Radium

Barium

Cadmium

TDS

The filters on an RO/DI filter are called stages. The first few stages consist of prefilters that help protect the RO membrane. The first prefilter is a sediment filter. It helps remove large sediment. The next stage is a carbon filter which takes out chlorine. Some filters run two sediment and or two carbon filters. You start with a course filter and then go to a tighter one. From there we go into the RO membrane. The last stage is running the water though a DI filter this takes out the last bit of contaminates that the RO can’t get. The DI filter will take out anything with an ionic charge. You can run two DI filters to get the maximum amount of life out of your DI resin. This is a digram of an RO/DI filter.

An important thing to note about RO filters is that the membrane is flushed with water the whole time you are running the filter. The water that’s used to flush the membrane is waste water. The amount of waste water your filter will produce is giving in a ratio so for example a filter might say it has a 3:1 waste water ratio. For every one gallon of good water you make you will make 3 of waste water. Let’s say we want to make 5 gallons of water for our tank that means we will end up with 15 gallons of waster water and we will end up running 20 gallons of water through the filter. There are a few things we can do to lower the amount of waste water the filter will produce. We can run two RO membranes. We could also run a booster pump to feed the filter.

There are a few things we can do to get the maximum amount of life out of our filters. We can test the water for Cl after the last carbon filter to tell us when to change the carbon out. We can also put a pressure gauge before the RO membrane when we see the pressure drop this lets us know the prefilters are starting to plug and we should change them. We can also add a flush kit to the RO membrane. This allows water to bypass the flow restrictor and flush the membrane clean. The membrane should be flushed before and after each use. You can buy an automatic flush kit which will flush the membrane for you. This will help extend the life of the RO which is the most expensive to replace. The flow restrictors job is to keep the membrane under pressure. The last thing we can do is use a TDS meter. There are two types inline and hand held. If we test the TDS after the DI resin anything higher then 0 tells you it’s time to change the resin. We can find out how well our membrane is preforming by testing the TDS of our tap water and the TDS after the RO membrane. Let’s say we have tap water that’s 200 TDS and after the RO we get 4 TDS our rejection rate is:

4/200=0.02

100(0.02)=2

100-2=98%

Once the rejection rate starts dropping by 3 or 4 % it’s time to start thinking of replacing the membrane. The membrane should tell you the expected rejection rate you will get.

There are a few things that can cause an RO/DI filter not to work well. One is if your on well water and your water has CO2 in it. If that’s the case then we need to degass the water before we run it though the DI filter. This can be done by collecting the water after the RO and putting and air stone in it. Let it sit for a day then use a small pump to run it through the DI resin or something like this can be made to degass the water as your running.

DIY CO2 Degassing Chamber for RO/DI

Well, I learned the hard way that the water coming out of my well has a high CO2 content. I burned through a pound of DI resin and only got 40 gallons out of it.... To keep this from happening again, I could either buy lots of RO/DI water or remove the CO2 from the RO water before I pass it...

www.reef2reef.com

www.reef2reef.com

Another potential problem is if your water is treated with Chloramines. If that’s the case then you need to run an additional prefilter.

BRS Universal Carbon Block Filter - 1 Micron

Why does BRS recommend this? We spent a ton of time researching and testing to find the best carbon block available while still being reasonable when it comes to price. There are other filters that work well however do not last as long. By simply just looking down the center of the carbon block...

An RO/DI filter looks like this. You can see the 2nd RO on top of the main one and you can see the flow restrictor in the 2nd picture.

An automatic RO/DI flush kit looks like this.

And a booster pump looks like this:

Last edited: