Hi fellow reef junkies, I though I would share the adventure of building my reef tank.

Probably like so many out there, I used the covid-19 lockdown to justify a foray into saltwater aquariums. So, after 4 months of intense focused research the plans were in place, and the minister of finance was vaguely on board, concerned, albeit not too much with the impending credit card implosion as she figured there wasn't really a chance that i would even attempt a project as insane as this...I love being underestimated....it adds flavour to the marriage!

I must stress that his was a risky project as I managed to pull it off (so far) without ever having set foot in a single brick and mortar aquarium store as everything was done online and delivered by courier service.

I ordered a custom made tank 100 gallon (50"x19"x24") and 60 gallon refugium sump (40"x18"19") and began to collect all the working parts. I had wanted to get a AIO Reef tank but would have had to get rid of some furniture including my previous custom designed tank cabinet. The solution was simple...obviously cut a hole in the floor and pipe to the boiler room in the basement and place the sump there. Err...people do it all the time don't they?

Its important to understand the difference between a Eurobraced tank and a rimless one. Apparently I didn't. Regardless the eurobraced looked good and was on its way. The boiler room now needed attention.

I built a mockup of the sump tank and tried my hand at woodwork, annoying the hell out of customers at Home Depot as I cut all 40 of my pieces.

The RODI was installed as well as the water tanks and the shelves to house the gadgets and the future dosing equipment. Struggled to level the old chest of drawers but got it done, but it had me wondering about its load bearing capacity. And then the worst realization hit: my ground floor was not going to be able to hold the display tank. The tank was going to be positioned parallel (not perpendicular) to the floor joists, AND only lying over ONE joist...basically against all the structural rules. After obtaining a 3 hr online PhD in structural engineering I realized I had dangerous knoweldge and had to call in a real engineer. So I did, and he inspected and confirmed the project needed some jackpost intervention. I had already bought them in anticipation so the project was back on track. It was at this point my wife began making a few calls to our insurance company to see if we were covered for a Noah's Ark type event.

Piping was installed and more holes made in the precious dining room wall and floor for the bean-animal style overflow system planned. I generally used 1inch schedule 40 pvc piping but to bend pipes between floors i had to use flexible pipe. People generally avoid this piping for certain reasons so i was nervous. But what the heck, i added enough unions and glue and crossed my fingers nothing leaked. I tried to minimise 90 degree bends for the return pump so as not to lose pressure entering the tank over 8ft above. I lazily ignored my buddy's advice to do some flow calculations and hoped that the Jebao 1700-2600 gal/hr DC pump would suffice. By this time I realized the chest of drawers was not going to hold up the sump so i replaced it with sexy looking concrete blocks. Notice one of the jackposts already installed to support the empty tank directly above.

Blacking out the back and side panel where the overflow box went was an interesting exercise. I was going to paint it with black latex paint for easy removal, but was convinced by a few people to use vinyl film. The film went on but not without hassle. It looks fine, but if i had to do it again I would rather slap a few coats of paint on instead as I can still still see the film's texture against the glass. While the tank was being leak tested I began trying to figure out the right Liferock configuration. I had splurged and ordered some not-so-cheap shrooms and was curious to see how they would look, so I tried to a mock-up with the cardboard representing the height of the tank.

Unfortunately I'm no stone mason so cutting them to get them to balance correctly was out of the question. the best i could do was stand one upright and the other upside down. The thought of it crashing through my 0.5 inch starphire glass at 2am in the morning brought shivers down my spine.

Sand and rock went in after the leak tests revealed that I had miraculously glued everything well enough. Had I fastened all the unions and gate and ball valves and checked the O-rings? Had I put clamps around the pipe connected to the return pump? heck no....lots of small leaks sprung up that had to be systematically adjusted but there were no real issues except forgetfulness. The hardest part was not letting my wife see the panic in my eyes or voice as I sprinted between floors with towels in hand thinking i had bitten off more project than I could chew.

Apparently 4 yrs of university chemistry did not pay off and in trying to get my pH above 7.6 I managed to form a white coating of what I imagine was CaCO3 over everything as it precipitated out. I hadnt gotten my water chemistry test kits yet so was bound to have issues.

At this point i also found out that my primary 300w heater wouldnt fit in my massive sump as it was too long for even my biggest compartment, so had to promote my secondary 250W heater and use a small auxiliary one as the backup in the sump.

The tank cycling went well. Took a good deal longer than i thought it would using Liferock, Livesand and Dr Tims. Probably due to me over cooking the initial ammonia mix to get things going...Note to internet...we need more instructions on mixing powdered ammonia when you cant get your hands on unscented, pure liquid form...and no, i wasnt brave enough to throw in a dead shrimp or pee in the tank to kick start it, lol. Talk about bonding with your tank. I kept an excel spreadsheet to keep things in check.....mostly my eagerness.

At this point i was still trying to work out the GHL Profilux 4 and the heating controls, or even figure out the temperature i wanted for the tank. I also installed most of the probes and was then faced with a mess of wires from all the gadgets. Apparently you CAN have too many gadgets. Ok, dont let anyone ever tell you that.

I put together the Red Sea mesh cover which, if any of you have replaced screen door mesh before that your mother-in-law has bolted through, you will agree its not the most fun job in the world. But in the end I was happy with the result and how neat it looked. I bought extra parts so that i could zigzag the frame around the 2 lights etc, but after realizing that the eurobrace had eliminated that issue I then had a simpler task for the cover construction.

I then installed the cabinet for all the cables and a cable tray and went berserk with the label maker. And installed the second jackpost. By this time i also had had my skimmer up and running for a couple of weeks but was still trying to fine tune it.

For the final job and to add a bit of flair i decided to cut out a clownfish shape into the box cover.

Then followed the obligatory livestock additions. I started with a pair of clowns, then 2 weeks later some cleaner crew and a yellow coris wrasse and a small cyphastrea and psammacora. Nowhere was chaeto to be found within 1000km so i settled on Dragons breath in the interim for the refugium. 2 weeks after that I added a rose bubbletipped anemone (BTA) and a Sunrise Dottyback. With the last addition also came 5 trochus snails to augment my existing 10 trochus (and 2 Ceriths, and 5 Nassarius) as i had suddenly aquired an outbreak of dynoflaggelates with their brown string and bubbles beginning to take over. I'm quite happy to see how quickly the snails have taken up their role and really kept the dynos in check.

Next job is learning more about corals and when to worry about polyp growth or when to be patient.

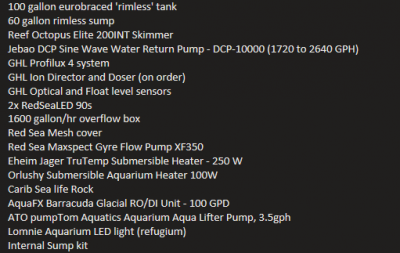

Equipment used:

100 gallon eurobraced 'rimless' tank

60 gallon rimless sump

Reef Octopus Elite 200INT Skimmer

Jebao DCP Sine Wave Water Return Pump - DCP-10000 (1720 to 2640 GPH)

GHL Profilux 4 system

GHL Ion Director and Doser (on order)

GHL Optical and Float level sensors

GHL Cooling fan (hahaha never going to need em here)

2x RedSeaLED 90s

1600 gallon/hr overflow box

Red Sea Mesh cover

Red Sea Maxspect Gyre Flow Pump XF350

Eheim Jager TruTemp Submersible Heater - 250 W

Orlushy Submersible Aquarium Heater 100W

Carib Sea life Rock

AquaFX Barracuda Glacial RO/DI Unit - 100 GPD

ATO pumpTom Aquatics Aquarium Aqua Lifter Pump, 3.5gph

Lomnie Aquarium LED light (refugium)

Internal Sump kit

Lessons learned:

Cheers and keep safe!

Probably like so many out there, I used the covid-19 lockdown to justify a foray into saltwater aquariums. So, after 4 months of intense focused research the plans were in place, and the minister of finance was vaguely on board, concerned, albeit not too much with the impending credit card implosion as she figured there wasn't really a chance that i would even attempt a project as insane as this...I love being underestimated....it adds flavour to the marriage!

I must stress that his was a risky project as I managed to pull it off (so far) without ever having set foot in a single brick and mortar aquarium store as everything was done online and delivered by courier service.

I ordered a custom made tank 100 gallon (50"x19"x24") and 60 gallon refugium sump (40"x18"19") and began to collect all the working parts. I had wanted to get a AIO Reef tank but would have had to get rid of some furniture including my previous custom designed tank cabinet. The solution was simple...obviously cut a hole in the floor and pipe to the boiler room in the basement and place the sump there. Err...people do it all the time don't they?

Its important to understand the difference between a Eurobraced tank and a rimless one. Apparently I didn't. Regardless the eurobraced looked good and was on its way. The boiler room now needed attention.

I built a mockup of the sump tank and tried my hand at woodwork, annoying the hell out of customers at Home Depot as I cut all 40 of my pieces.

The RODI was installed as well as the water tanks and the shelves to house the gadgets and the future dosing equipment. Struggled to level the old chest of drawers but got it done, but it had me wondering about its load bearing capacity. And then the worst realization hit: my ground floor was not going to be able to hold the display tank. The tank was going to be positioned parallel (not perpendicular) to the floor joists, AND only lying over ONE joist...basically against all the structural rules. After obtaining a 3 hr online PhD in structural engineering I realized I had dangerous knoweldge and had to call in a real engineer. So I did, and he inspected and confirmed the project needed some jackpost intervention. I had already bought them in anticipation so the project was back on track. It was at this point my wife began making a few calls to our insurance company to see if we were covered for a Noah's Ark type event.

Piping was installed and more holes made in the precious dining room wall and floor for the bean-animal style overflow system planned. I generally used 1inch schedule 40 pvc piping but to bend pipes between floors i had to use flexible pipe. People generally avoid this piping for certain reasons so i was nervous. But what the heck, i added enough unions and glue and crossed my fingers nothing leaked. I tried to minimise 90 degree bends for the return pump so as not to lose pressure entering the tank over 8ft above. I lazily ignored my buddy's advice to do some flow calculations and hoped that the Jebao 1700-2600 gal/hr DC pump would suffice. By this time I realized the chest of drawers was not going to hold up the sump so i replaced it with sexy looking concrete blocks. Notice one of the jackposts already installed to support the empty tank directly above.

Blacking out the back and side panel where the overflow box went was an interesting exercise. I was going to paint it with black latex paint for easy removal, but was convinced by a few people to use vinyl film. The film went on but not without hassle. It looks fine, but if i had to do it again I would rather slap a few coats of paint on instead as I can still still see the film's texture against the glass. While the tank was being leak tested I began trying to figure out the right Liferock configuration. I had splurged and ordered some not-so-cheap shrooms and was curious to see how they would look, so I tried to a mock-up with the cardboard representing the height of the tank.

Unfortunately I'm no stone mason so cutting them to get them to balance correctly was out of the question. the best i could do was stand one upright and the other upside down. The thought of it crashing through my 0.5 inch starphire glass at 2am in the morning brought shivers down my spine.

Sand and rock went in after the leak tests revealed that I had miraculously glued everything well enough. Had I fastened all the unions and gate and ball valves and checked the O-rings? Had I put clamps around the pipe connected to the return pump? heck no....lots of small leaks sprung up that had to be systematically adjusted but there were no real issues except forgetfulness. The hardest part was not letting my wife see the panic in my eyes or voice as I sprinted between floors with towels in hand thinking i had bitten off more project than I could chew.

Apparently 4 yrs of university chemistry did not pay off and in trying to get my pH above 7.6 I managed to form a white coating of what I imagine was CaCO3 over everything as it precipitated out. I hadnt gotten my water chemistry test kits yet so was bound to have issues.

At this point i also found out that my primary 300w heater wouldnt fit in my massive sump as it was too long for even my biggest compartment, so had to promote my secondary 250W heater and use a small auxiliary one as the backup in the sump.

The tank cycling went well. Took a good deal longer than i thought it would using Liferock, Livesand and Dr Tims. Probably due to me over cooking the initial ammonia mix to get things going...Note to internet...we need more instructions on mixing powdered ammonia when you cant get your hands on unscented, pure liquid form...and no, i wasnt brave enough to throw in a dead shrimp or pee in the tank to kick start it, lol. Talk about bonding with your tank. I kept an excel spreadsheet to keep things in check.....mostly my eagerness.

At this point i was still trying to work out the GHL Profilux 4 and the heating controls, or even figure out the temperature i wanted for the tank. I also installed most of the probes and was then faced with a mess of wires from all the gadgets. Apparently you CAN have too many gadgets. Ok, dont let anyone ever tell you that.

I put together the Red Sea mesh cover which, if any of you have replaced screen door mesh before that your mother-in-law has bolted through, you will agree its not the most fun job in the world. But in the end I was happy with the result and how neat it looked. I bought extra parts so that i could zigzag the frame around the 2 lights etc, but after realizing that the eurobrace had eliminated that issue I then had a simpler task for the cover construction.

I then installed the cabinet for all the cables and a cable tray and went berserk with the label maker. And installed the second jackpost. By this time i also had had my skimmer up and running for a couple of weeks but was still trying to fine tune it.

For the final job and to add a bit of flair i decided to cut out a clownfish shape into the box cover.

Then followed the obligatory livestock additions. I started with a pair of clowns, then 2 weeks later some cleaner crew and a yellow coris wrasse and a small cyphastrea and psammacora. Nowhere was chaeto to be found within 1000km so i settled on Dragons breath in the interim for the refugium. 2 weeks after that I added a rose bubbletipped anemone (BTA) and a Sunrise Dottyback. With the last addition also came 5 trochus snails to augment my existing 10 trochus (and 2 Ceriths, and 5 Nassarius) as i had suddenly aquired an outbreak of dynoflaggelates with their brown string and bubbles beginning to take over. I'm quite happy to see how quickly the snails have taken up their role and really kept the dynos in check.

Next job is learning more about corals and when to worry about polyp growth or when to be patient.

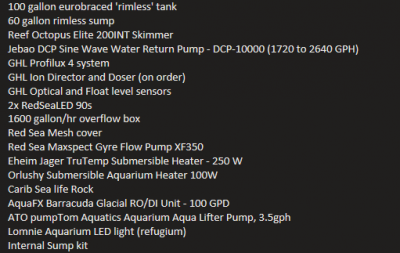

Equipment used:

100 gallon eurobraced 'rimless' tank

60 gallon rimless sump

Reef Octopus Elite 200INT Skimmer

Jebao DCP Sine Wave Water Return Pump - DCP-10000 (1720 to 2640 GPH)

GHL Profilux 4 system

GHL Ion Director and Doser (on order)

GHL Optical and Float level sensors

GHL Cooling fan (hahaha never going to need em here)

2x RedSeaLED 90s

1600 gallon/hr overflow box

Red Sea Mesh cover

Red Sea Maxspect Gyre Flow Pump XF350

Eheim Jager TruTemp Submersible Heater - 250 W

Orlushy Submersible Aquarium Heater 100W

Carib Sea life Rock

AquaFX Barracuda Glacial RO/DI Unit - 100 GPD

ATO pumpTom Aquatics Aquarium Aqua Lifter Pump, 3.5gph

Lomnie Aquarium LED light (refugium)

Internal Sump kit

Lessons learned:

- Dont rush to get an anemone - even though its gorgeous. Then again, I only have 2 corals so maybe it wasnt a bad thing to get it in early. Seems to be doing fine.

- Expect to go at least 50% over budget, and also realize your toolbox is probably way underequiped.

- Have a plan for dealing with Courier companies. Living 8 hrs from Toronto means getting live animals during covid is at the mercy of Fedex. Plan well.

- All-in-one tanks....I'd be all set by now if i had chosen one...and closer to budget. But would i have learned as much or had as much DIY fun? Definitely not. But, might try one next time.

- Sandsifting starfish - dont get it too early. It stresses me out watching it race around the tank then submerge for a day. Still looks healthy after 3 weeks but sure is a weird one.

- I would probably use less rock and have more space for cleaning

Cheers and keep safe!