Hey Guys. Been though all of your videos, everyone's threads regarding... well everything GHL & PL etc.

I just want to have you all double check this and a few questions before I set this up. Everything is ready, just waiting to program.

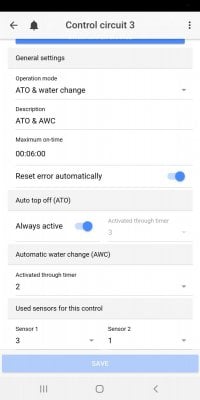

Setting up an AWC with the Maxi / ATO function.

(2) float switches for high / low. WC & ATO - #1 & #3

(2) float Switches for Low reservoirs | ATO #4 & Mixing # 2

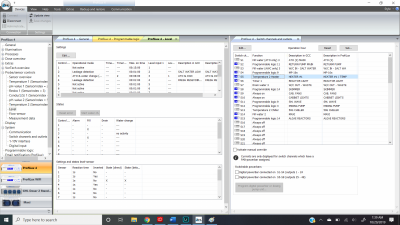

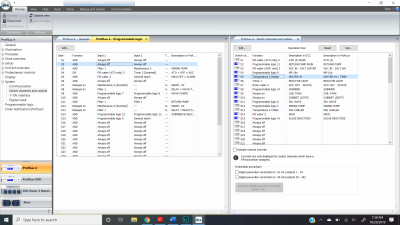

SC are as follows:

12 -Mixing pump - Set to Maintenance mode #3- manual (only equipment activated during)

7 - WC Out / dirty - Doser #5

3 - WC In / Clean - Doser #6

1 - ATO

15 - Reactors - only equipment that needs to be shut down during WC schedule. - Need PL

I am going to set the timer functions as described with ATO / AWC for the float switches and dosers.

*Now, setting up the PL for the reactor, and possible any other equipment to shut off during this is where I am asking, cant afford another flood because I forgot something simple overlooked, like a inverted sensor...

Its an AIO tank, so the amount of water removed doesn't affect anything else really, minimal WC daily. (as all equipment was form by Large tank breakdown)

PL - making sure the WC function is off during Low Level alarms, I believe these are set to Leak Detection inverted.

Any other advice, or PL safety / redundancy I should look into? Basically starting over on all PL functions as the floats and ato etc will be changed.

Thanks,

Josh

I just want to have you all double check this and a few questions before I set this up. Everything is ready, just waiting to program.

Setting up an AWC with the Maxi / ATO function.

(2) float switches for high / low. WC & ATO - #1 & #3

(2) float Switches for Low reservoirs | ATO #4 & Mixing # 2

SC are as follows:

12 -Mixing pump - Set to Maintenance mode #3- manual (only equipment activated during)

7 - WC Out / dirty - Doser #5

3 - WC In / Clean - Doser #6

1 - ATO

15 - Reactors - only equipment that needs to be shut down during WC schedule. - Need PL

I am going to set the timer functions as described with ATO / AWC for the float switches and dosers.

*Now, setting up the PL for the reactor, and possible any other equipment to shut off during this is where I am asking, cant afford another flood because I forgot something simple overlooked, like a inverted sensor...

Its an AIO tank, so the amount of water removed doesn't affect anything else really, minimal WC daily. (as all equipment was form by Large tank breakdown)

PL - making sure the WC function is off during Low Level alarms, I believe these are set to Leak Detection inverted.

Any other advice, or PL safety / redundancy I should look into? Basically starting over on all PL functions as the floats and ato etc will be changed.

Thanks,

Josh