Hi All,

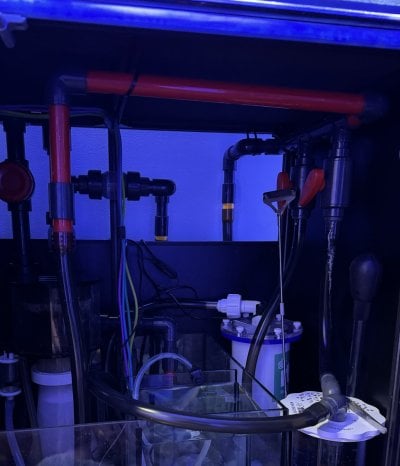

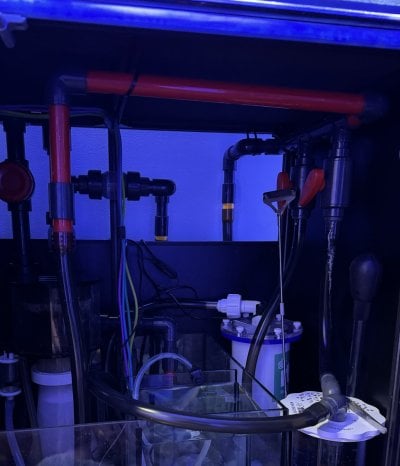

Ive attached some pictures of my DIY manifold I put on my water box tank. I built this one myself but now having used it for a few months I realise it has some serious functionality/design flaws - primarily a loss of head pressure feeding through the UV and back up into the display. After getting my desired flow through the reactors I’m left with a trickle feeding back in to the display once I turn the main return pump off.

I would appreciate some advice on how this should be modified or rebuilt to increase flow through the UV steriliser and up to the display. At the moment the UV is off because I know it would not have sufficient flow coming through and the Main return is running at higher setting to compensate for reduced flow coming from the other pump.

It uses a 6000 LPH running on max to feed a media reactor and an algae reactor, each with ball valves to regulate flow to the requirements of each reactor. The plumbing then takes a dive back down to floor level into my UV before heading back into the main return which is plumbed to a Vectra M2. I have used one way valves to try to ensure the two pumps aren’t fighting each other where they meet. I suspect my issues are because I’ve either got too many 90 degree bends or because I’ve gone down to the UV which is slightly below the level of the pump and all the way up the weir again and the water is pooling in the UV, but don’t know enough to be sure trying to eliminate these things would help or what to attack first.

Advice much appreciated on how this can be done better.

Ive attached some pictures of my DIY manifold I put on my water box tank. I built this one myself but now having used it for a few months I realise it has some serious functionality/design flaws - primarily a loss of head pressure feeding through the UV and back up into the display. After getting my desired flow through the reactors I’m left with a trickle feeding back in to the display once I turn the main return pump off.

I would appreciate some advice on how this should be modified or rebuilt to increase flow through the UV steriliser and up to the display. At the moment the UV is off because I know it would not have sufficient flow coming through and the Main return is running at higher setting to compensate for reduced flow coming from the other pump.

It uses a 6000 LPH running on max to feed a media reactor and an algae reactor, each with ball valves to regulate flow to the requirements of each reactor. The plumbing then takes a dive back down to floor level into my UV before heading back into the main return which is plumbed to a Vectra M2. I have used one way valves to try to ensure the two pumps aren’t fighting each other where they meet. I suspect my issues are because I’ve either got too many 90 degree bends or because I’ve gone down to the UV which is slightly below the level of the pump and all the way up the weir again and the water is pooling in the UV, but don’t know enough to be sure trying to eliminate these things would help or what to attack first.

Advice much appreciated on how this can be done better.