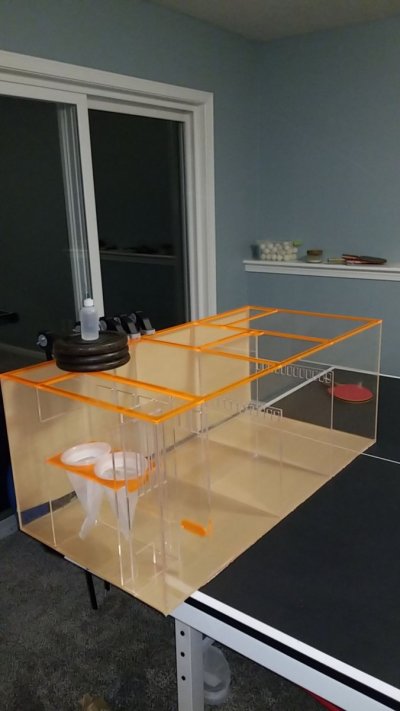

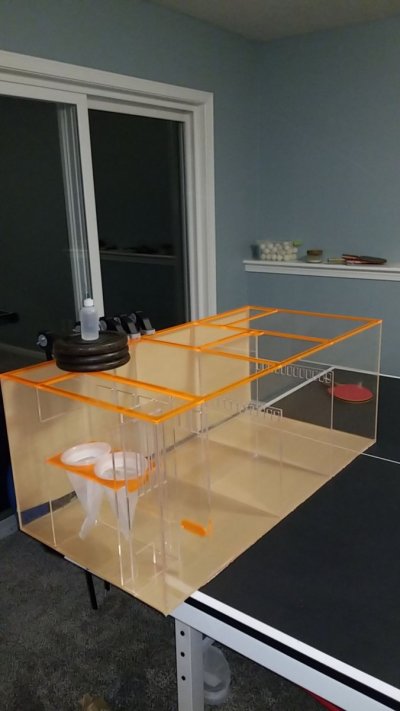

Hey guys, I just finished up my two month long build process, from 2D Design, 3D design, sourcing Acrylic during an Acrylic shortage, sourcing a reliable CNC shop for my product, and designing a logo. I've designed and built everything myself, and wanted to share with you guys my finished product. I am definitely looking for constructive criticism as I have two local shop display orders to fulfil by late spring mid summer as well as some at cost testers. I will be running a quality test for 6 months, but I am very happy to say the bonding with Weld on 4 went spectacular and I have mirror finish clear bonds all the way around. Water Test was a success.

It really is stunning in person, I will get my DSLR and take some accurate pictures later, not tacky at all!

First build post:

Customizable in design and color (I have Blue, Green, Orange, Yellow, Red, and Purple) This current one for my 150, is an Apex themed sump with a rim that will glow orange once a low wattage UV led strip is installed in cabinet (This won't affect the growth of algae, even a simple refugium light would reflect light all inside the rim). Along with that, opaque grey lids to match the Apex Neptune aesthetic. I've got a pending trademark for "PlasmaSumps" to start a trial production of these sumps with a local glass/acrylic manufacturer to fit a demand for sumps under or in the $500-$600 range (UPDATE: I made it well below this and I am in the $400 retail price range, at cost for those who want to get a test run will be lower priced). I will be working on a Nano option next. This sump will be entirely made of Domestic Cell Cast Acrylic of reputable brands, either Polycast, Polyone, Arkema ( I went with this), or Reynolds R for its quality and strength. REMINDER: This is a personal project for my 150, I would not be upset if this idea actually took off and people actually wanted one as I am going through my first prototype.

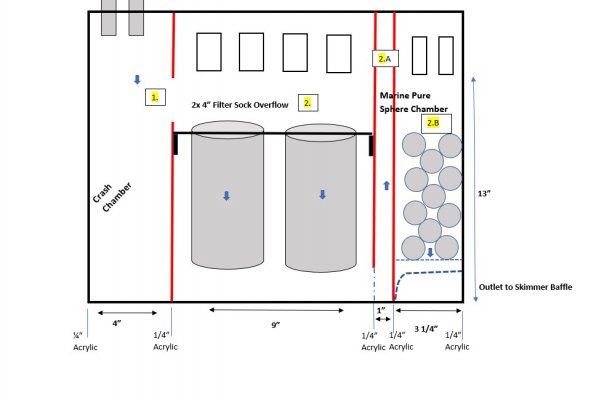

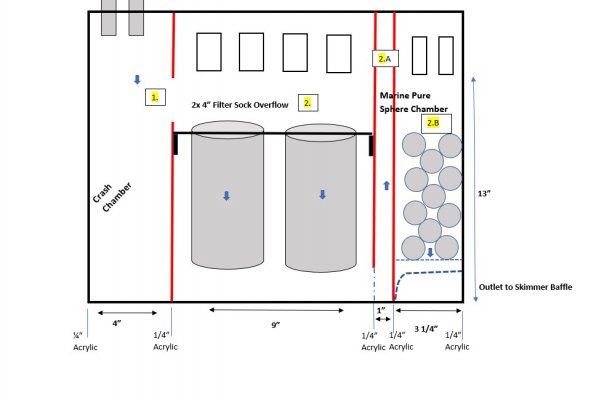

UPDATE: ALL my baffles and the Rim are made out of 1/4" Domestic Cell Cast

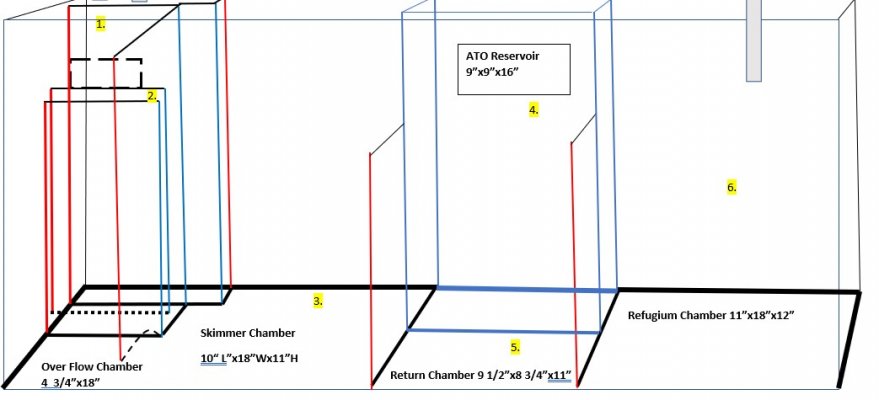

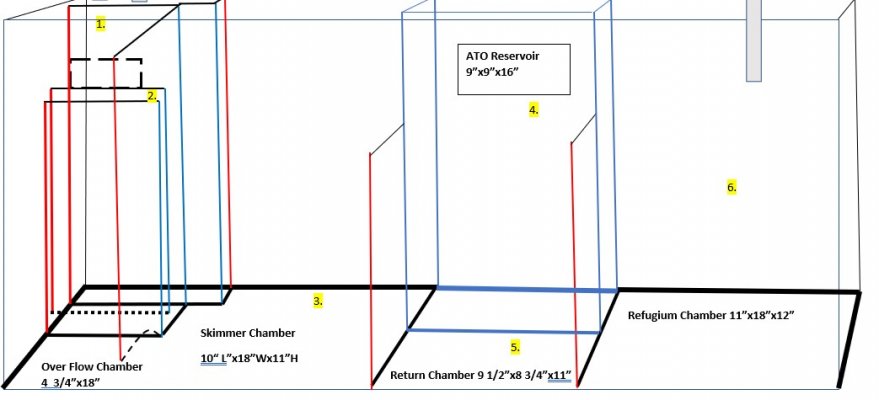

This build has 3 x 1" bulkheads

1. Crash area/drain from DT ( top right of the rim, has two bulk heads built into removable lid)

2.Filter Sock Chamber, goes through the filter socks, down through a panel, up through a bubble trap, through some slits and goes down a marine pure ball chamber, or biological media of your choice) second chamber highlighted by the rim on the second far left section. PLATE FOR FILTER SOCKS IS REMOVABLE.

3. Skimmer, Media Reactor, dosing chamber

4.Ato tank is the top middle section (Holds 5 Gallons with several inches of space left)

5. In front of the ATO Chamber is the return pump ( I could move these two chambers to the end, but I wanted my refugium on the end so that I can split the flow 75/25 from the DT, 25% goes to the refugium)

6/7. Refugium. 10 gallons filled

I figured having it go mechanical filtration (socks), biological filtration (marine pure balls), and then the mechanical/chemical filtration (skimmer/reactor) picking up excess bacteria and fine waste particles would make for a clean sump/system. All chambers including the holder for the filter socks, and marine pure balls are accessible for cleaning.

Skimmer chamber is large enough for several brands like Eshop, Reef Octopus, Aquavitros new skimmer, etc. Return area is 9"x9"x11", plenty of room for most return pumps that would be needed on a 55-250 gal. A lot of time went into the planning too. The prototype is running for 6 months but I am fairly confident in the bonding as every edge came out with a mirror finish when the weld on 4 was applied, all it comes down to is running it so any changes I have to the files, I can make them within that time frame.

The colored part is an 1" wide, it doesn't inhibit any maintenance. I have a pretty average cabinet space and was able to work fairly easy removing and replacing skimmer, and I do have a fairly large skimmer, working on the return pump, removing compartments like the sock holder, all lids removed, fairly easy. I listed all of the chambers in the first page incase you care to look

It really is stunning in person, I will get my DSLR and take some accurate pictures later, not tacky at all!

First build post:

Customizable in design and color (I have Blue, Green, Orange, Yellow, Red, and Purple) This current one for my 150, is an Apex themed sump with a rim that will glow orange once a low wattage UV led strip is installed in cabinet (This won't affect the growth of algae, even a simple refugium light would reflect light all inside the rim). Along with that, opaque grey lids to match the Apex Neptune aesthetic. I've got a pending trademark for "PlasmaSumps" to start a trial production of these sumps with a local glass/acrylic manufacturer to fit a demand for sumps under or in the $500-$600 range (UPDATE: I made it well below this and I am in the $400 retail price range, at cost for those who want to get a test run will be lower priced). I will be working on a Nano option next. This sump will be entirely made of Domestic Cell Cast Acrylic of reputable brands, either Polycast, Polyone, Arkema ( I went with this), or Reynolds R for its quality and strength. REMINDER: This is a personal project for my 150, I would not be upset if this idea actually took off and people actually wanted one as I am going through my first prototype.

UPDATE: ALL my baffles and the Rim are made out of 1/4" Domestic Cell Cast

This build has 3 x 1" bulkheads

1. Crash area/drain from DT ( top right of the rim, has two bulk heads built into removable lid)

2.Filter Sock Chamber, goes through the filter socks, down through a panel, up through a bubble trap, through some slits and goes down a marine pure ball chamber, or biological media of your choice) second chamber highlighted by the rim on the second far left section. PLATE FOR FILTER SOCKS IS REMOVABLE.

3. Skimmer, Media Reactor, dosing chamber

4.Ato tank is the top middle section (Holds 5 Gallons with several inches of space left)

5. In front of the ATO Chamber is the return pump ( I could move these two chambers to the end, but I wanted my refugium on the end so that I can split the flow 75/25 from the DT, 25% goes to the refugium)

6/7. Refugium. 10 gallons filled

I figured having it go mechanical filtration (socks), biological filtration (marine pure balls), and then the mechanical/chemical filtration (skimmer/reactor) picking up excess bacteria and fine waste particles would make for a clean sump/system. All chambers including the holder for the filter socks, and marine pure balls are accessible for cleaning.

Skimmer chamber is large enough for several brands like Eshop, Reef Octopus, Aquavitros new skimmer, etc. Return area is 9"x9"x11", plenty of room for most return pumps that would be needed on a 55-250 gal. A lot of time went into the planning too. The prototype is running for 6 months but I am fairly confident in the bonding as every edge came out with a mirror finish when the weld on 4 was applied, all it comes down to is running it so any changes I have to the files, I can make them within that time frame.

The colored part is an 1" wide, it doesn't inhibit any maintenance. I have a pretty average cabinet space and was able to work fairly easy removing and replacing skimmer, and I do have a fairly large skimmer, working on the return pump, removing compartments like the sock holder, all lids removed, fairly easy. I listed all of the chambers in the first page incase you care to look

Last edited: