Hi

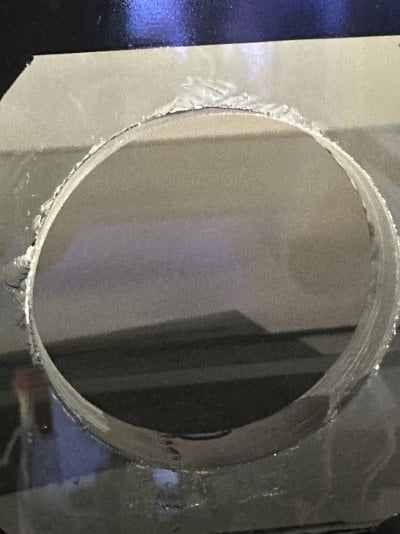

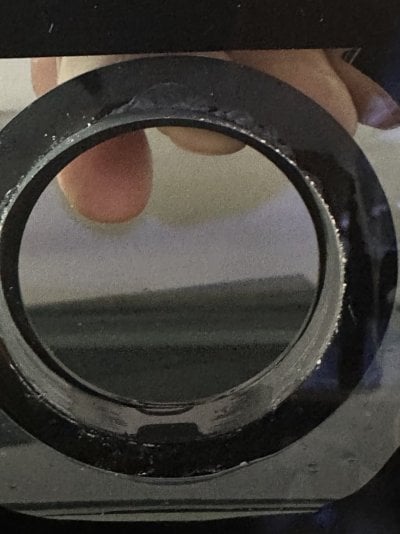

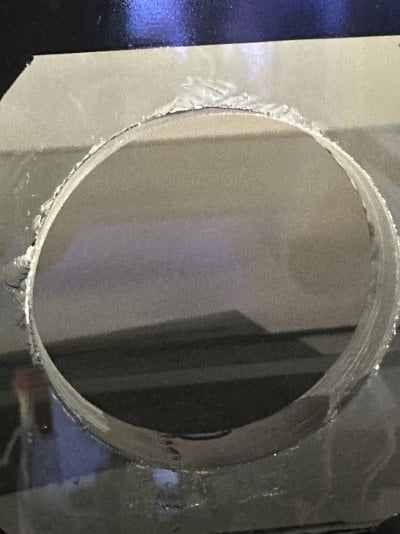

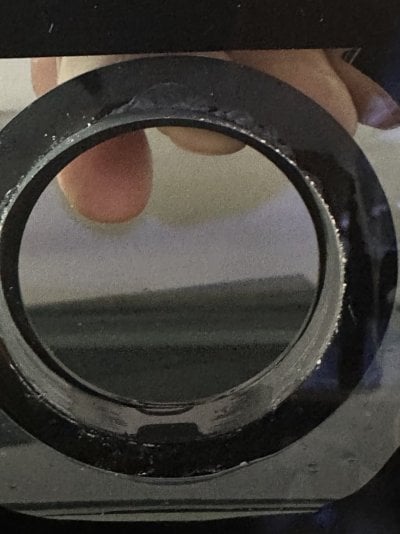

I recently posted on how to stop leak from new tank bulk head for shadow overflow. Attached are two pics. I see after I took off the overflow that I have the imperfections you can easily see. all defects of course are on the inside of the tank. The largest on the top and the left (at 9 oclock). Second pic shows how gasket will fit over the hole. It does cover easily with fair room to spare.

I jsut cut away the black film around the hole thinking that was cause of the leak (which still it could have been).

At least it's almost no pressure on teh hole, since its at top fo the tank. and no defects in bottom half really on either of the holes. I mention that since the overflow will be holding on the the holes, gravity can pull it downwards.

**I was reading for a similar situation, except the hole was on bottom of the tank, a suggestion was to silicone around perimeter of outside of the hole and affix the outside gasket to that to prevent any leaks that way. I was wondering should I do this to the inner gasket as well? The overflow has two gaskets per hole. One on the inside of tank wall and one on outside. the member suggesting this said it works for him/her.

I'm thinking that's the thing to do or no? What shoudl I do (hopefully not too difficult)

TIA

I recently posted on how to stop leak from new tank bulk head for shadow overflow. Attached are two pics. I see after I took off the overflow that I have the imperfections you can easily see. all defects of course are on the inside of the tank. The largest on the top and the left (at 9 oclock). Second pic shows how gasket will fit over the hole. It does cover easily with fair room to spare.

I jsut cut away the black film around the hole thinking that was cause of the leak (which still it could have been).

At least it's almost no pressure on teh hole, since its at top fo the tank. and no defects in bottom half really on either of the holes. I mention that since the overflow will be holding on the the holes, gravity can pull it downwards.

**I was reading for a similar situation, except the hole was on bottom of the tank, a suggestion was to silicone around perimeter of outside of the hole and affix the outside gasket to that to prevent any leaks that way. I was wondering should I do this to the inner gasket as well? The overflow has two gaskets per hole. One on the inside of tank wall and one on outside. the member suggesting this said it works for him/her.

I'm thinking that's the thing to do or no? What shoudl I do (hopefully not too difficult)

TIA