Hey Guys,

please know that english is not my native language. I'm sorry if i made grammer errors.

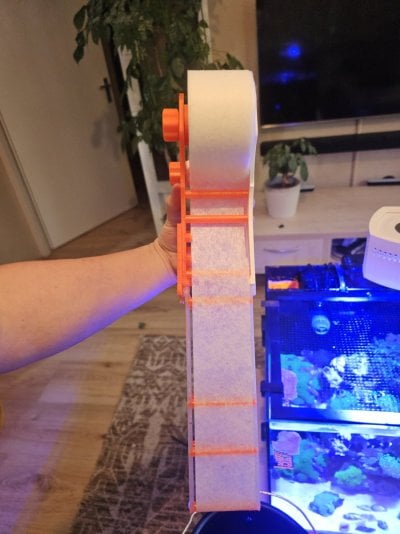

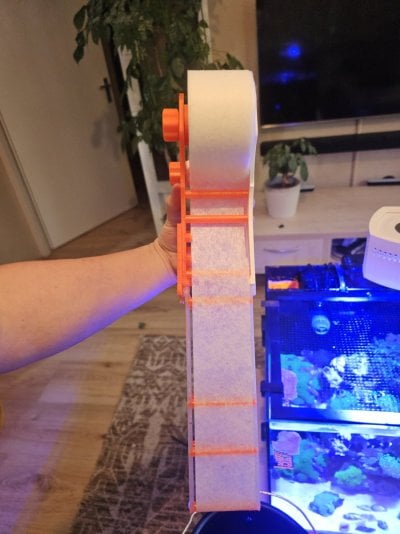

A while back I asked if if was possible to cut a fleece filter rol in half. i've never hold one in my hands at that point. There where some jokes made but that's what started this project.

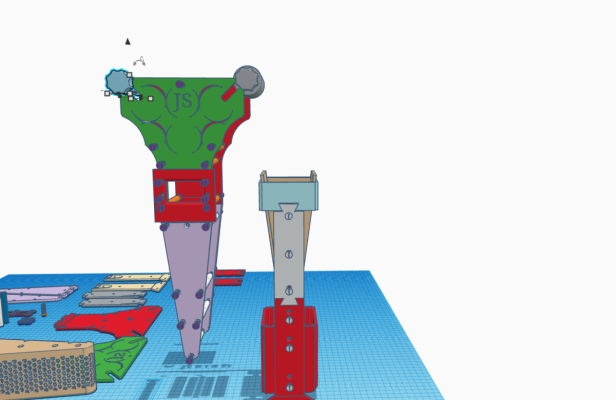

the filter is made for a waterbox nano (cube 10 20 penninsula 15 and 25) but can easily modded in to a different size chamber or even in a small sump ( that does take some modding).

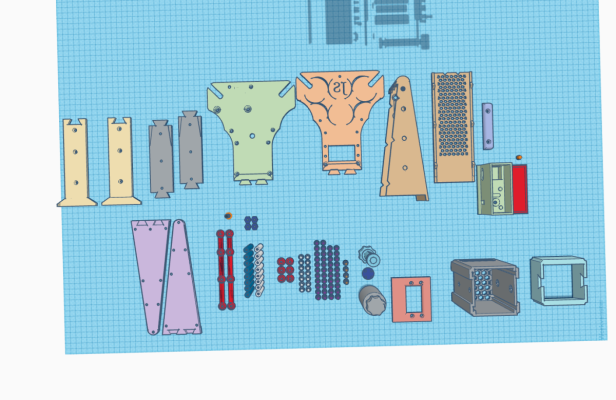

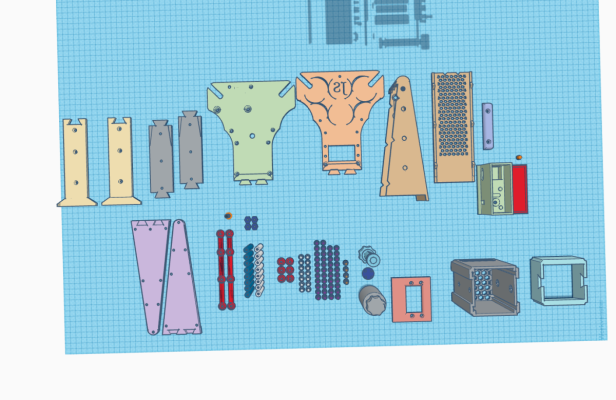

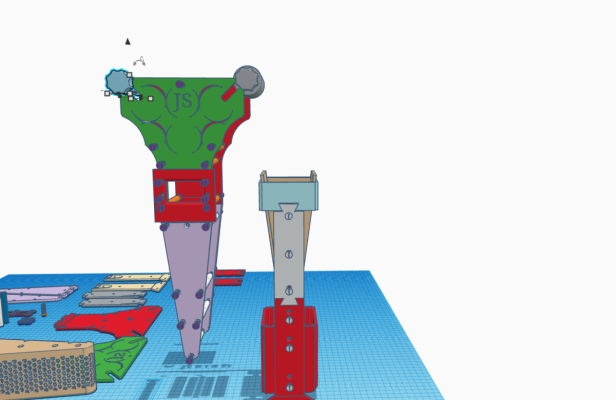

Rightnow I have it working well and i'm waiting for some magnets to arrive to make it motorised. I make this in tinkercad and that does take a lot of time but I do believe it's turning out great.

The whole design is screwed together with 3d printed screws. Only the fleece filter basket is glued together because if I want to print it in 1 part it takes 300 grams of support material.

The 2 filter baskets use inserts for the screws. This why the basket can be printed at a lower resolution.

The motor is a 23rpm dc motor from alieexpress and is going to be easily attachable and removable and hold inplace with magnets but the force of winding up the roll is not put upon the magnets.

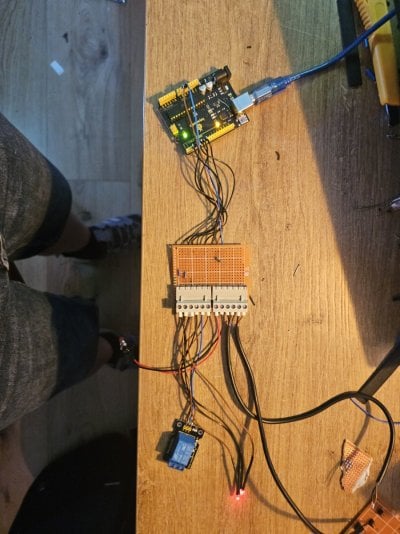

the motor is turned on and of by 2 water level sensors. 1 in the filter it self and 1 in the chamber next to it ( that one is upside down)

when water in filter is HIGH and the camber next to it is LOW the motor starts turning until the sensors turn off. It's really simple.

The whole project is open source. use it as you like as long as you upload your mods.

Edit: here you have the files:

www.tinkercad.com

www.tinkercad.com

please know that english is not my native language. I'm sorry if i made grammer errors.

A while back I asked if if was possible to cut a fleece filter rol in half. i've never hold one in my hands at that point. There where some jokes made but that's what started this project.

the filter is made for a waterbox nano (cube 10 20 penninsula 15 and 25) but can easily modded in to a different size chamber or even in a small sump ( that does take some modding).

Rightnow I have it working well and i'm waiting for some magnets to arrive to make it motorised. I make this in tinkercad and that does take a lot of time but I do believe it's turning out great.

The whole design is screwed together with 3d printed screws. Only the fleece filter basket is glued together because if I want to print it in 1 part it takes 300 grams of support material.

The 2 filter baskets use inserts for the screws. This why the basket can be printed at a lower resolution.

The motor is a 23rpm dc motor from alieexpress and is going to be easily attachable and removable and hold inplace with magnets but the force of winding up the roll is not put upon the magnets.

the motor is turned on and of by 2 water level sensors. 1 in the filter it self and 1 in the chamber next to it ( that one is upside down)

when water in filter is HIGH and the camber next to it is LOW the motor starts turning until the sensors turn off. It's really simple.

The whole project is open source. use it as you like as long as you upload your mods.

Edit: here you have the files:

3D design nano fleece filter for waterbox or nano reeftank - Tinkercad

3D design nano fleece filter for waterbox or nano reeftank

Last edited: