Yo yo! Whats up with them ATOs.....

Salinity is one of the major parameters within our systems that requires our attention to maintain. Differences in salt mixing procedure and products aside, the one factor affecting salinity that all aquarists have to manage is that of evaporation. It happens at different rates within each system depending on flow, air circulation, water temp, ambient humidity and I'm sure plenty of other factors that I cant seem to think of. Having covers on sumps and displays certainly helps slow down the inevitable, but it happens regardless. And since these amazing glass boxes are inside our homes, not receiving any rainwater or runoff, it falls upon us noble keepers of these watery denizens to replenish that which has been lost. Of course thanks to chemistry, and I'm sure some curious taste testers, we know that it is only the water component of the solution we contain that evaporates, not the salt and minerals. As the water leaves and the minerals stay the salinity increases, making the critters sad. So we wait until it feel like its worth it to run down to the RO/DI bin, fill a bucket, run back to the tank and dump a bucket in, making the critters mad............WRONG!!!

We invent Automatic Top Off systems!!!! Or ATOs as I have heard the kids call em. So I says to myself "I gotta get me one of those ATOs", and then I giggled cause it rhymed. But seriously, ATOs are an important part of maintaining stability and every system should have one. And the industry is very aware of that. There are many quality products out there to fill this nearly necessary component of any successful system. Just like with many gadgets in this craft, they ain't all cheap and they all have varying functions, pros/cons and user reviews. This felt like another brilliant opportunity to test my DIY chops and find a solution that fit my KISS ideal for my system. Of course I scrolled the boards here and a bit of YouTubing to see what others are coming up with. I found a great product that fills my desire to be able to create and maintain components of my system and push my comfort level and skill in problem solving. It has been working splendidly for me and I was please with the outcome, so I figured I should share. I wish there more photos but there wasn't a plan to post details.

BEHOLD.........THE AQUAHUB TOP-it-OFF Premium Kit!!!

Now is a good time for a disclaimer. I am not an electrician, electrical engineer, professional aquarist or scientist of any type. Just some guy who had dream of maintaining a sweet reef tank some day and trying to make it happen with in my means. This project does require wiring 120v connections and I would suggest a level of confidence and familiarity with that type of task. Back to the build.......

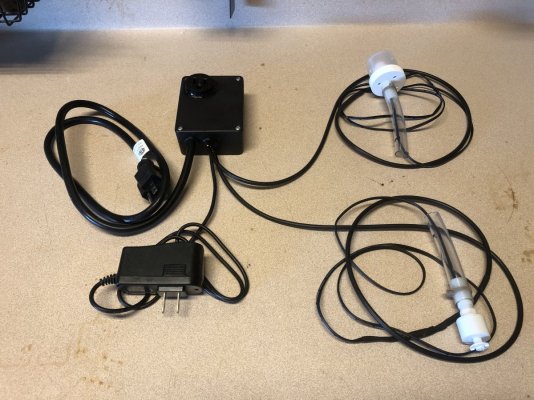

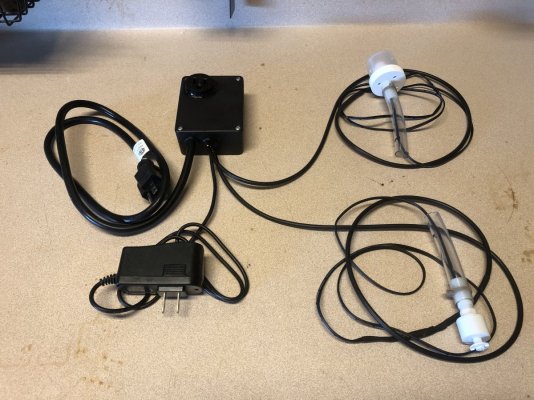

The product is a simple concept that doesn't offer anything it can't deliver. But as the assembly and directions read out and felt kinda clunky, I saw some opportunities for improvement The kit includes a couple magnetic float switches, a transformer to power them, a relay and socket to connect them to the delivery system, a box to cram it all into and a few accessory components. It is not all-in-one and, like most ATO systems, requires you to provide a few things. A reservoir, a small pump w/power supply, an extension cord and tubing to get it to the tank/sump are required to finish the assembly.

ATO reservoirs are one of the items in this craft that seem to be over engineered and overpriced. I have no doubt they perform their task brilliantly, but this was one area that was easy for me to replace with a simpler option.....a sealed pet food container that fits beside the sump. The pump, which is the heart and hardest working part of the ATO system, was one area that I wanted to be sure was a reliable piece of equipment. The Tunze Osmolator system is highly regarded product that is built around a solid little pump. So I picked up one of the Tunze 5000.02 metering pumps that they run them off of. It requires a 9v transformer to power, which I thankfully had laying around. A couple of holes get drilled in the container for the pump power supply and the water line, then lined with rubber grommets to seal them. The pump gets wired to the transform with the cable running through the grommet and the pump inside the container. All wire connections not in sealed enclosures should be spliced with water tight butt splices and shrink wrapped.

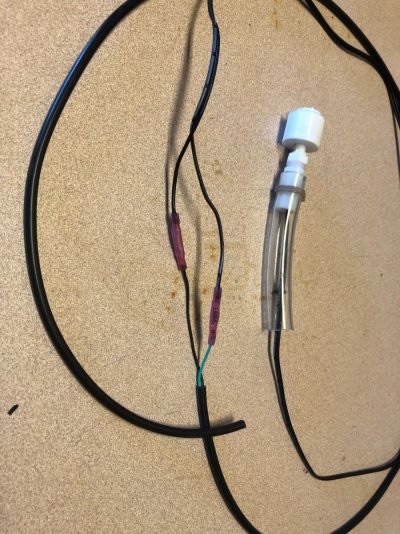

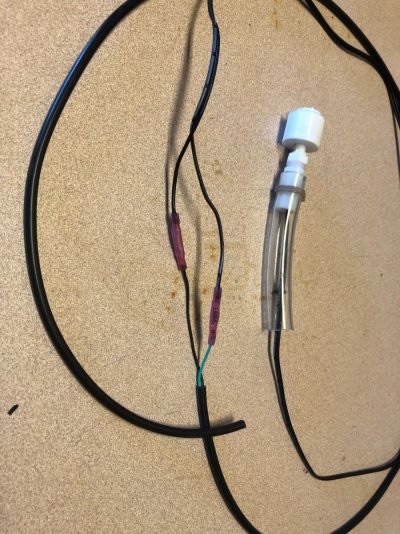

The float switches require a little prep work to prepare them for installation. There are 2 provided for redundancy. They are not entirely seal and require adding on a provided tubing adapter and a length of tubing to protect them in the event of water level increase and submersion. A provided guard should also be installed to protect the float mechanism form critters and growths, only on the main switch that is mostly submerged. In my case the wire leads on the floats were not long enough for my installation and needed to be extended. Again, I used shrink wrapped, water tight splices.

The project box that came the kit is adequate and easy enough to work with. It thankfully has room for me to make a couple improvements. The original assembly calls for an extension cord that you pull one line from the sheathing, cut it to connect to the relay and leave the rest of the wires intact. Though doable, it looks like the ugly hazard that it could be. Since the box was roomy enough, I decides to forgo the mangling of perfectly good extension cord. I found a 15amp female cord end, drilled hole in the box cover to accommodate it, glued it in place and sealed it with silicone. Two hole were also drilled and lined with grommets for the float switch lines as well as the power source.

The relay gets seated into the socket. And with barely enough room for slack wires, the float switches and a cord with a male end get connected to the socket. Its a fair amount of wires in the crammed little box, but they do indeed fit using the provided crimp connectors. Being that it was in an enclosed and sealable, water tight connections are not a concern here.

After carefully jumping on the assembly to get it all to fit , it got sealed up and a couple mounting tabs screwed to the back of the box. I think it ended up looking fairly clean and and improvement from the intended design.

, it got sealed up and a couple mounting tabs screwed to the back of the box. I think it ended up looking fairly clean and and improvement from the intended design.

The float switches get installed in the return chamber of the sump. Given proper sump design and flow any evaporation will manifest in the return chamber. The main float should be installed a few inches above the minimum operating depth for the return pump. The secondary switch gets installed slightly above that to stay mostly out of the water but engage if the main switch gets stuck. Here again I think I made a minor improvement. The kit comes with a wonderful piece of cuttable, moldable plastic that is intended to hold the floats. But I wanted the ability to adjust the water level if need be. The sump and return system should be designed to handle any water that may drain down in the event of a return pump failure. The tubing adapters for the float switches should extend above this maximum level or to the top of the sump for ease of mounting. I used a couple plastic cable clamps that would hold the 3/8" tubing and allow me to adjust the height. The relay box gets mounted, the reservoir set with water line ran into sump (I feel the equipment chamber is the best to dump cool RO/DI water) and the pump plugged into the relay box, relay box and floats plug into main GFCI source..........BOOM!!! NOW WE ATOin!!!!!!! *I would suggest doing a "dry run" to make sure it works prior to final installation*

Estimated Cost:

Aquahub kit - $35

Osamolator pump - $25

Pet food container - $10

Wall wart, tubing, splices, etc. - $20

The way I figure, any key component to our systems that we can provide for a startup cost of less than <$100 and requires minimal maintenance is a solid victory. Not to mention a deeper understanding of your system, easily replaced and maintained components and a great project for anyone with a bit of a tinkering bug........I just had to share!!!

Full disclosure: This is part of the first reef system I have ever set up, which has only been running for 4 months at the time of writing this. It has been working thus far. Please do feel free to point out any faults and flaws, ask questions and suggest any improvement or ideas relating to this project. Hope someone finds some use outta this

Reef HARD yo!!!!

Salinity is one of the major parameters within our systems that requires our attention to maintain. Differences in salt mixing procedure and products aside, the one factor affecting salinity that all aquarists have to manage is that of evaporation. It happens at different rates within each system depending on flow, air circulation, water temp, ambient humidity and I'm sure plenty of other factors that I cant seem to think of. Having covers on sumps and displays certainly helps slow down the inevitable, but it happens regardless. And since these amazing glass boxes are inside our homes, not receiving any rainwater or runoff, it falls upon us noble keepers of these watery denizens to replenish that which has been lost. Of course thanks to chemistry, and I'm sure some curious taste testers, we know that it is only the water component of the solution we contain that evaporates, not the salt and minerals. As the water leaves and the minerals stay the salinity increases, making the critters sad. So we wait until it feel like its worth it to run down to the RO/DI bin, fill a bucket, run back to the tank and dump a bucket in, making the critters mad............WRONG!!!

We invent Automatic Top Off systems!!!! Or ATOs as I have heard the kids call em. So I says to myself "I gotta get me one of those ATOs", and then I giggled cause it rhymed. But seriously, ATOs are an important part of maintaining stability and every system should have one. And the industry is very aware of that. There are many quality products out there to fill this nearly necessary component of any successful system. Just like with many gadgets in this craft, they ain't all cheap and they all have varying functions, pros/cons and user reviews. This felt like another brilliant opportunity to test my DIY chops and find a solution that fit my KISS ideal for my system. Of course I scrolled the boards here and a bit of YouTubing to see what others are coming up with. I found a great product that fills my desire to be able to create and maintain components of my system and push my comfort level and skill in problem solving. It has been working splendidly for me and I was please with the outcome, so I figured I should share. I wish there more photos but there wasn't a plan to post details.

BEHOLD.........THE AQUAHUB TOP-it-OFF Premium Kit!!!

Now is a good time for a disclaimer. I am not an electrician, electrical engineer, professional aquarist or scientist of any type. Just some guy who had dream of maintaining a sweet reef tank some day and trying to make it happen with in my means. This project does require wiring 120v connections and I would suggest a level of confidence and familiarity with that type of task. Back to the build.......

The product is a simple concept that doesn't offer anything it can't deliver. But as the assembly and directions read out and felt kinda clunky, I saw some opportunities for improvement The kit includes a couple magnetic float switches, a transformer to power them, a relay and socket to connect them to the delivery system, a box to cram it all into and a few accessory components. It is not all-in-one and, like most ATO systems, requires you to provide a few things. A reservoir, a small pump w/power supply, an extension cord and tubing to get it to the tank/sump are required to finish the assembly.

ATO reservoirs are one of the items in this craft that seem to be over engineered and overpriced. I have no doubt they perform their task brilliantly, but this was one area that was easy for me to replace with a simpler option.....a sealed pet food container that fits beside the sump. The pump, which is the heart and hardest working part of the ATO system, was one area that I wanted to be sure was a reliable piece of equipment. The Tunze Osmolator system is highly regarded product that is built around a solid little pump. So I picked up one of the Tunze 5000.02 metering pumps that they run them off of. It requires a 9v transformer to power, which I thankfully had laying around. A couple of holes get drilled in the container for the pump power supply and the water line, then lined with rubber grommets to seal them. The pump gets wired to the transform with the cable running through the grommet and the pump inside the container. All wire connections not in sealed enclosures should be spliced with water tight butt splices and shrink wrapped.

The float switches require a little prep work to prepare them for installation. There are 2 provided for redundancy. They are not entirely seal and require adding on a provided tubing adapter and a length of tubing to protect them in the event of water level increase and submersion. A provided guard should also be installed to protect the float mechanism form critters and growths, only on the main switch that is mostly submerged. In my case the wire leads on the floats were not long enough for my installation and needed to be extended. Again, I used shrink wrapped, water tight splices.

The project box that came the kit is adequate and easy enough to work with. It thankfully has room for me to make a couple improvements. The original assembly calls for an extension cord that you pull one line from the sheathing, cut it to connect to the relay and leave the rest of the wires intact. Though doable, it looks like the ugly hazard that it could be. Since the box was roomy enough, I decides to forgo the mangling of perfectly good extension cord. I found a 15amp female cord end, drilled hole in the box cover to accommodate it, glued it in place and sealed it with silicone. Two hole were also drilled and lined with grommets for the float switch lines as well as the power source.

The relay gets seated into the socket. And with barely enough room for slack wires, the float switches and a cord with a male end get connected to the socket. Its a fair amount of wires in the crammed little box, but they do indeed fit using the provided crimp connectors. Being that it was in an enclosed and sealable, water tight connections are not a concern here.

After carefully jumping on the assembly to get it all to fit

The float switches get installed in the return chamber of the sump. Given proper sump design and flow any evaporation will manifest in the return chamber. The main float should be installed a few inches above the minimum operating depth for the return pump. The secondary switch gets installed slightly above that to stay mostly out of the water but engage if the main switch gets stuck. Here again I think I made a minor improvement. The kit comes with a wonderful piece of cuttable, moldable plastic that is intended to hold the floats. But I wanted the ability to adjust the water level if need be. The sump and return system should be designed to handle any water that may drain down in the event of a return pump failure. The tubing adapters for the float switches should extend above this maximum level or to the top of the sump for ease of mounting. I used a couple plastic cable clamps that would hold the 3/8" tubing and allow me to adjust the height. The relay box gets mounted, the reservoir set with water line ran into sump (I feel the equipment chamber is the best to dump cool RO/DI water) and the pump plugged into the relay box, relay box and floats plug into main GFCI source..........BOOM!!! NOW WE ATOin!!!!!!! *I would suggest doing a "dry run" to make sure it works prior to final installation*

Estimated Cost:

Aquahub kit - $35

Osamolator pump - $25

Pet food container - $10

Wall wart, tubing, splices, etc. - $20

The way I figure, any key component to our systems that we can provide for a startup cost of less than <$100 and requires minimal maintenance is a solid victory. Not to mention a deeper understanding of your system, easily replaced and maintained components and a great project for anyone with a bit of a tinkering bug........I just had to share!!!

Full disclosure: This is part of the first reef system I have ever set up, which has only been running for 4 months at the time of writing this. It has been working thus far. Please do feel free to point out any faults and flaws, ask questions and suggest any improvement or ideas relating to this project. Hope someone finds some use outta this

Reef HARD yo!!!!