What ATO type do you use for ATO functionality with your profilux?

I have run 2 sensors for my AWC on the Maxi 2.2 doser for about a month and just got another sensor to replace my current ATO set-up (Hydor Smart Level Controller).

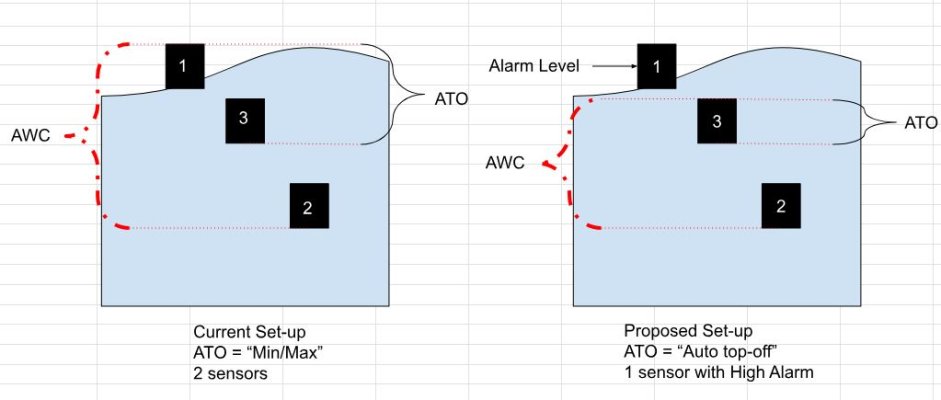

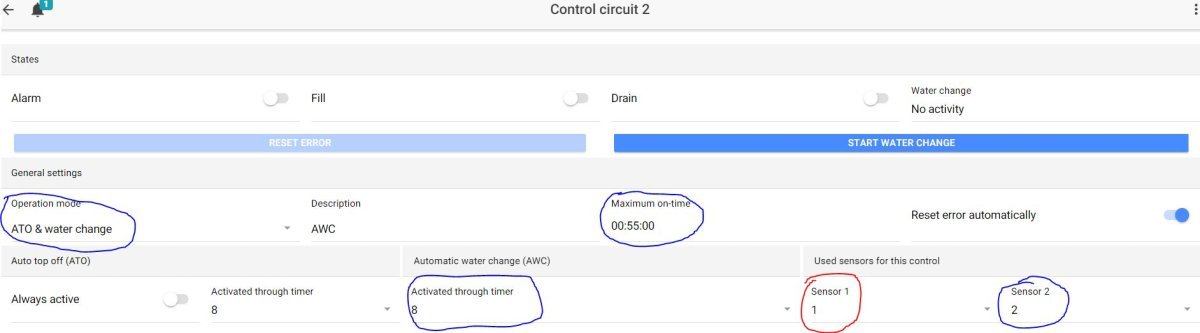

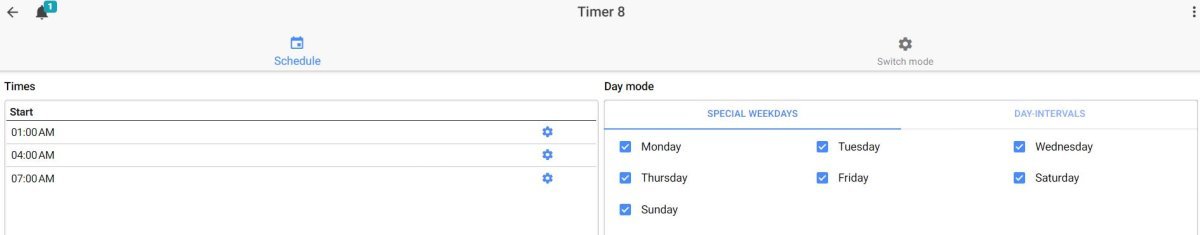

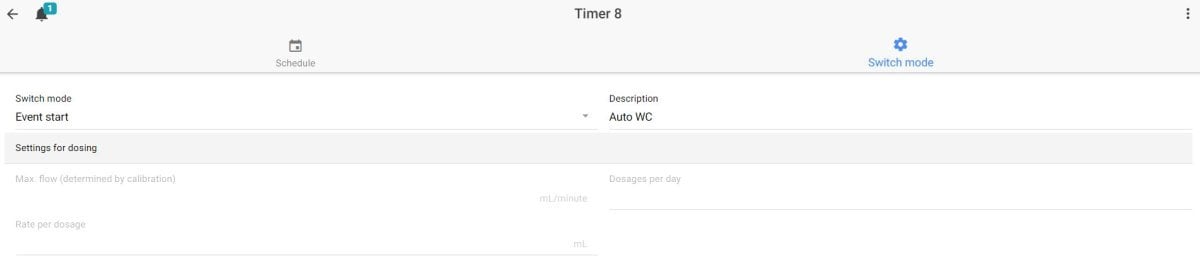

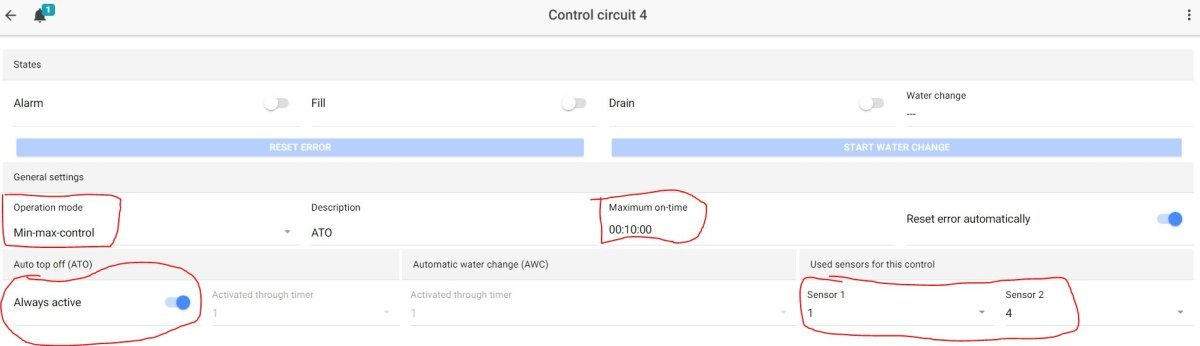

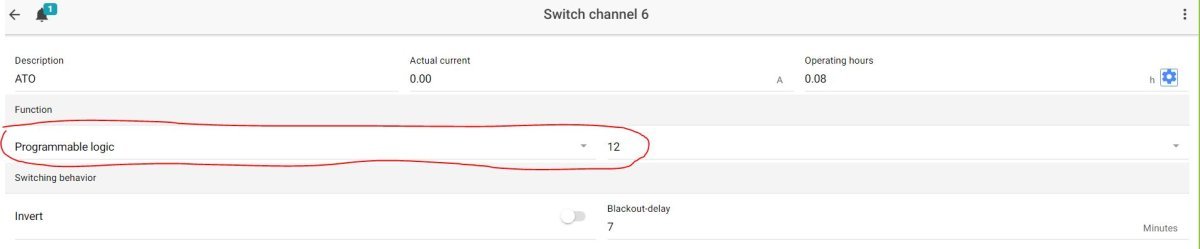

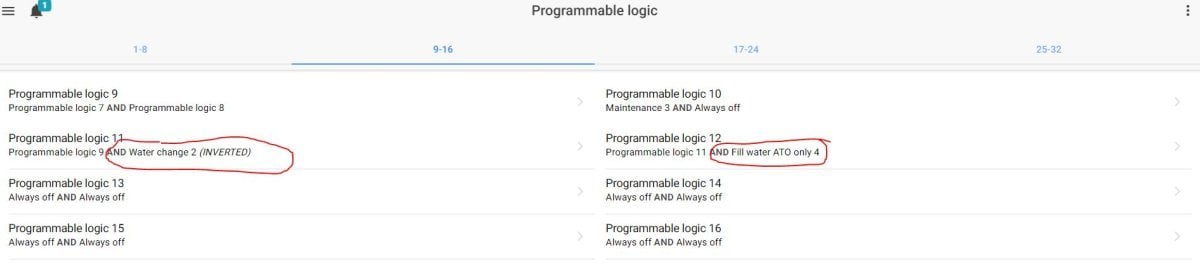

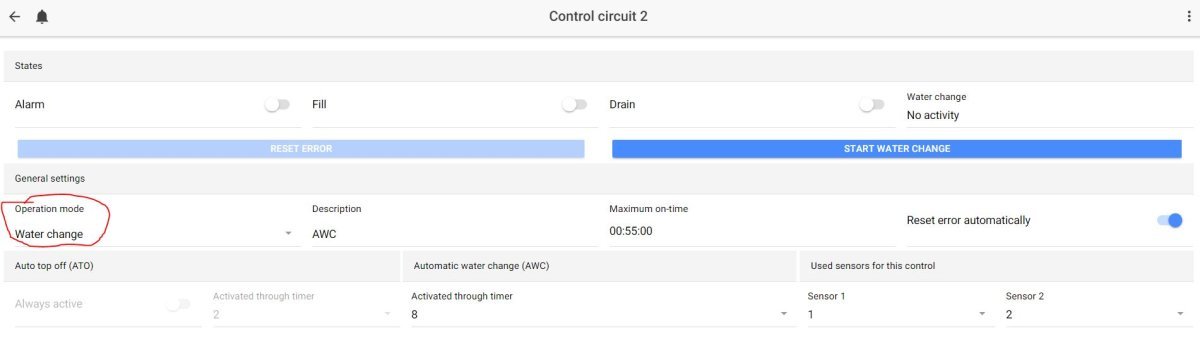

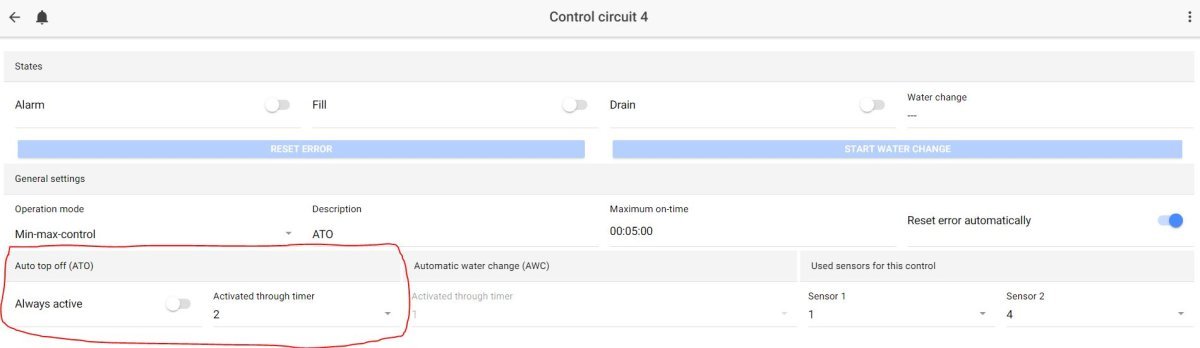

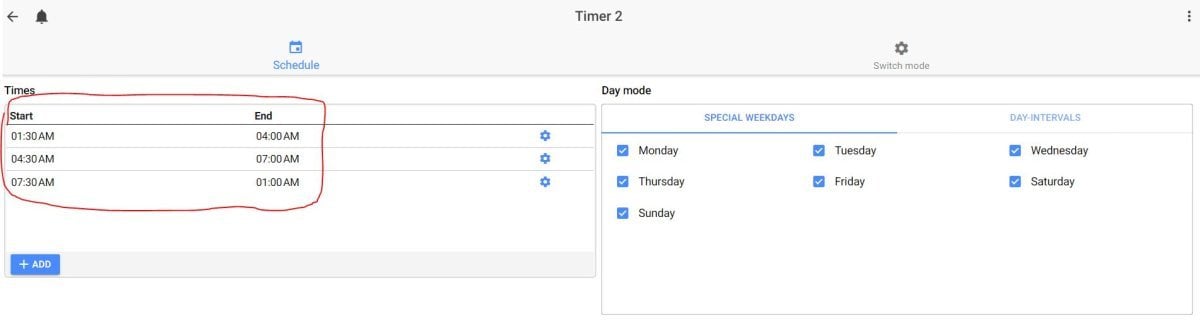

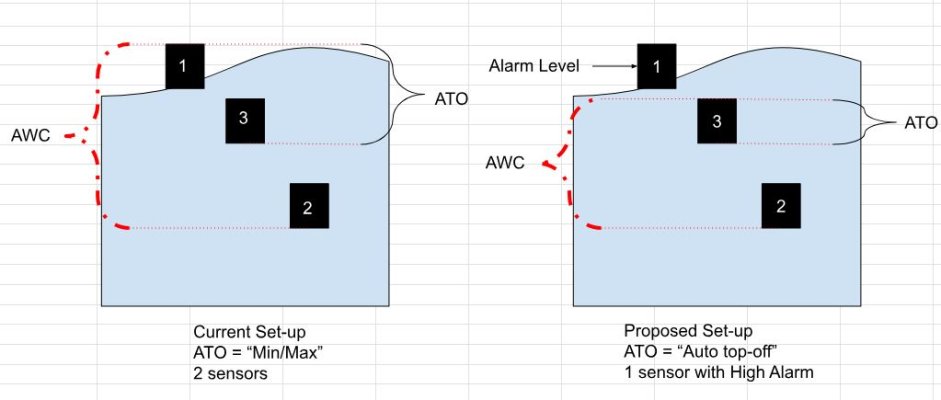

Sensor 1 (Top) and 2 (Bottom) are used for my AWC and spaced ~2" apart. I added my 3rd sensor (Middle) about 1/2" from Sensor 1 (Top) and set the ATO function to "Min/Max" utilizing Sensor 1 (Top) and 3 (Middle). My only concern is this "removes" my high water alarm that I had on my previous ATO. I do have a run-time alarm turned on.

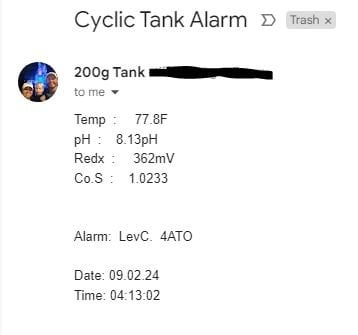

I'm wondering though if I should use ATO in 1-sensor mode using Sensor 3 (Middle), change AWC to use Sensor 3 and Sensor 2, and use Sensor 1 as the high Alarm. The idea of having 2 failsafe methods makes me more at ease (Run-time alarm on ATO AND Sensor 1 alarm). What I'm not sure of exactly, is how a 1-sensor ATO with a float switch works with the system. There's about 0.5" movement in the float, is that the change in sump level during an ATO event?

Does anyone have any thoughts?

I have run 2 sensors for my AWC on the Maxi 2.2 doser for about a month and just got another sensor to replace my current ATO set-up (Hydor Smart Level Controller).

Sensor 1 (Top) and 2 (Bottom) are used for my AWC and spaced ~2" apart. I added my 3rd sensor (Middle) about 1/2" from Sensor 1 (Top) and set the ATO function to "Min/Max" utilizing Sensor 1 (Top) and 3 (Middle). My only concern is this "removes" my high water alarm that I had on my previous ATO. I do have a run-time alarm turned on.

I'm wondering though if I should use ATO in 1-sensor mode using Sensor 3 (Middle), change AWC to use Sensor 3 and Sensor 2, and use Sensor 1 as the high Alarm. The idea of having 2 failsafe methods makes me more at ease (Run-time alarm on ATO AND Sensor 1 alarm). What I'm not sure of exactly, is how a 1-sensor ATO with a float switch works with the system. There's about 0.5" movement in the float, is that the change in sump level during an ATO event?

Does anyone have any thoughts?